In this case-study, a small-scale biogas system was introduced in order to generate both energy for home consumption and fertilizer. Small-scale biogas systems are implemented in different parts of the world, however the layout thereof varies considerably.

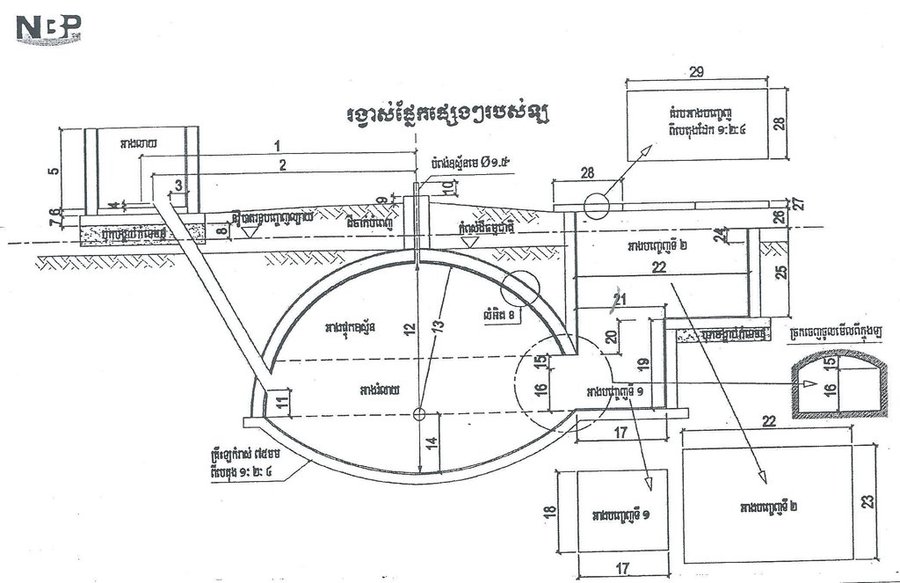

The model used in this case-study consists of different components (cf. technical drawing). First, there is an inlet where the land user puts cow manure mixed with water. On the bottom of the inlet, there is a board which closes the access to the bio-digester situated beneath the inlet. The board can be opened manually by pulling a string. Once the board is open, the fluid components go through a pipe which leads to the bio-digester. In the bio-digester, bacteria transform the organic matter into biogas (mainly methane and CO2) and slurry. At the other end of the digester, there is another pipe (outlet). The outlet is lower than the inlet, and due to the difference in pressure, the slurry is pushed out of the digester. The slurry is dried and applied to the fields two to three times a year with the help of an ox cart. It has similar effects on the plant growth as chemical fertilizer as it does not build up the soil organic matter as much as compost. The biogas, however, is pushed to the pipe situated on top of the digester and can be utilized for domestic uses. The gas is used for cooking and lighting.

The use of biogas allows reducing the expenses on charging batteries for the lighting, as well as reducing the firewood use (usually from deforestation) for cooking. The slurry reduces the expenses on chemical fertilizer in the fields and has the advantage of killing the weed and rice seeds present in the manure and crop residues.

For building the biogas system, there is governmental and NGO support. These two actors finance half of the construction costs. The other half is paid by the land user. Building a biogas system is quite costly, with about 400 $, and not all of the land users in the area can afford paying 50% of its price. However, the costs borne by the land user are paid off within a few years due to reduced expenses on firewood, chemical fertilizer, and charging batteries. The construction itself was undertaken by local companies.

The costs are paid off within a few years due to the reduced expenses on firewood, chemical fertilizer and battery charging.

The analysed area is flat (slope < 2%), tropic (dry and wet season), and the soils are mostly sandy or loamy. The soils contain little organic matter (low soil fertility, acidification, small amount of cattle, area has been deforested a long time ago) and the groundwater table is rather high (1-3 m during the dry season, on the surface during wet season).

Due to climate change, the rainfalls are more erratic, temperatures rise and droughts are more recurrent. Rice is the predominant crop grown in the area, since it serves as staple food (mix subsistence and commercial activities). Rice is often grown in monocultures and harvested once a year. Once the rice is harvested (dry season), the cattle are released to the paddy fields. The cattle is often replaced by hand tractors, which effects the production of manure but allows a higher amount of crop residues on the fields.

As an addition to rice, most land users grow vegetable and fruits in small home gardens (subsistence) and complement their income by producing handicrafts or through off farm income / remittances from family members working in other places. The increasing migration rate (the young generation leaves the villages to work in the cities, garment industry or abroad) results in a decrease of available labour force in the area which has detrimental effects on the agricultural activities. Furthermore, the civil war in the 1970s (Khmer Rouge) led to the loss of agricultural knowledge which different NGOs try to re-establish.

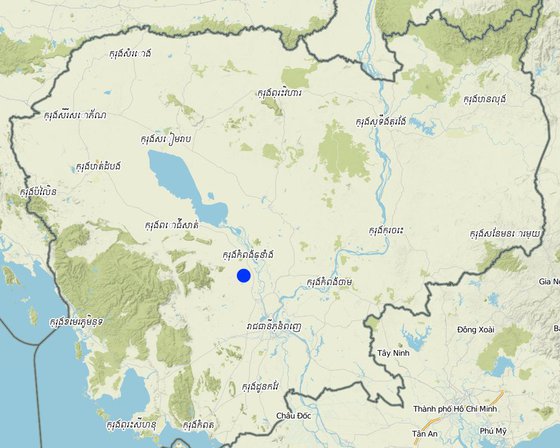

Location: Sre Ouk Samlor Sap/Taing Krasaing/Rolear Pha,er, Kampong Chhnang, Cambodia

No. of Technology sites analysed:

Spread of the Technology: evenly spread over an area (approx. 0.1-1 km2)

In a permanently protected area?:

Date of implementation: less than 10 years ago (recently)

Type of introduction

| Specify input | Unit | Quantity | Costs per Unit (Riel) | Total costs per input (Riel) | % of costs borne by land users |

| Construction material | |||||

| Construction of biodigester | 1.0 | 400.0 | 400.0 | 50.0 | |

| Total costs for establishment of the Technology | 400.0 | ||||

| Total costs for establishment of the Technology in USD | 0.1 | ||||

| Specify input | Unit | Quantity | Costs per Unit (Riel) | Total costs per input (Riel) | % of costs borne by land users |

| Labour | |||||

| Labour | 1.0 | 121.5 | 121.5 | 100.0 | |

| Total costs for maintenance of the Technology | 121.5 | ||||

| Total costs for maintenance of the Technology in USD | 0.03 | ||||

Dried residues are put in the garden (cucumber, pumpkin, watermelon) which increases nutrient availability.

He saves 50 $ on chemical fertilizer per year.

No smoke from open fire.

On the long term livelihood is improved, because he saves over 60 $ per year in firewood and battery charging for light, as well as 50 $ for chemical fertilizer.

Pollution of groundwater due to washing out of nutrients.

Most of the carbon is transformed into methane, not available as organic matter.

Compost usually not completely decomposed, as well as raw manure, contain lots of weed seeds.

Before the installation of the biogas system, the land user bought firewood.

Sludge is left to dry outside, nutrients washed out into groundwater. Not measurable.