In Kenya stone lines are mostly practiced in areas that receive 200-750 mm of annual rainfall with a spacing of 15-30 m between them. They are particularly common in areas where rocks are readily available, such as Mbeere, Laikipia, Baringo, Mwingi, Kitui and Tharaka. Since the stonelines are permeable they do not pond runoff water but instead, they slow down the speed, filter it and spread the water over the field, thus enhancing water infiltration and reducing soil erosion. They are built in series running along the slope. In addition, the stone barrier blocks and settles down the sediments transported from the upper slopes.

Purpose of the Technology: They are often used to rehabilitate eroded and abandoned land. The advantages of stonelines include; slowing down the runoff thereby increasing infiltration and soil moisture. They also induce a natural process of terracing, reducing erosion and rehabilitation of eroded lands by trapping silt. They are easy to design and construct and since the stone line structure is permeable there is no need for construction of spillways to drain the excess runoff water. When it rains, the soil builds up on the upslope side of the stonelines and over time a natural terrace is formed.

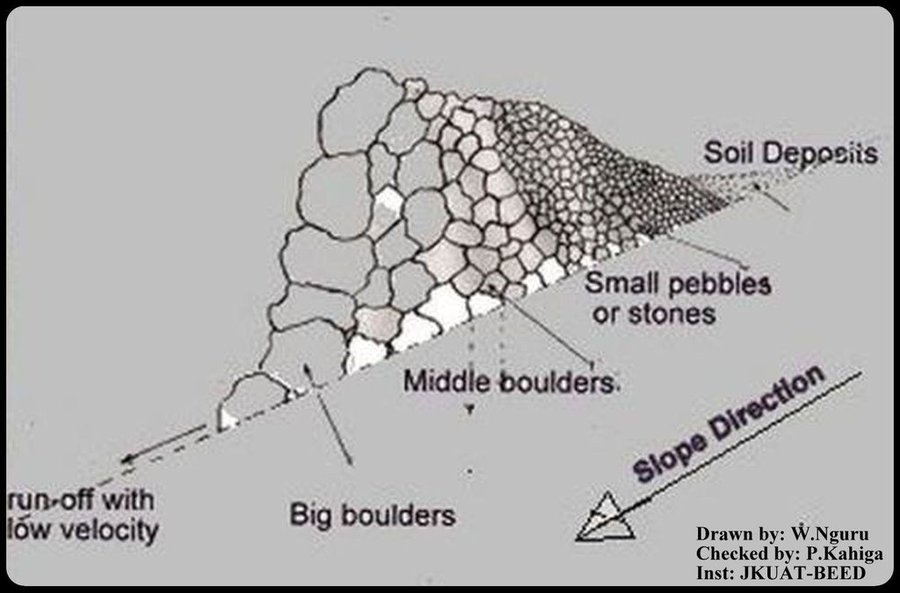

Establishment / maintenance activities and inputs: The stonelines are spaced 15-30 m apart, a shorter distance being used for the steeper slopes. Stonelines are normally suitable on gentle slopes. Slopes above 35% should be avoided. They are established in the following manner: first, the contour line are marked out with the help of a tube level or line levels. In this region here, it is done with the help of the frontline agricultural extension officers. Secondly, a shallow foundation trench is dug across the slope (5-10 cm to 30 cm deep) using basic farm equipments (jembes or hoes). As shown on the above photographs, the larger stones are put on the down slope side of the trench while the smaller stones are used to build the rest of the bund. The smallest stones are used to fill the gaps and increase the heights of the bunds up to the desired level. Farmers plant fruit trees (pawpaws) as show in the photograph above on the upper part. The trees utilises the moisture and rich sediments deposited on the upper part. The stonelines can be reinforced with earth, or crop residues to make them more stable. Maintenance of stonelines is done by repairing the already damaged /fallen stoneline that may have been knocked down or disarranged by livestock or by human beings. In this case animal access needs to be limited and/or the bund should be laid out in a way that allows the animals to pass through.

Natural / human environment: In the lower Mbeere South District where the stoneline technologies is largely practiced, unless there are stones in the individual farms, it might be difficult to import stones from other farms as the exercise can be labor intensive. In this catchment, the Ministry of Agriculture through the front line extension officers has taken a lead role in encouraging farmers to adopt the technology especially the farms which have many stones. Most of the farmers who have implemented this technology in the Lower Mbeere South District learn from the ones who are already practicing through field days or individual initiatives.

Location: Mbeere South District, Eastern Province, Kenya

No. of Technology sites analysed:

Spread of the Technology: evenly spread over an area (approx. < 0.1 km2 (10 ha))

In a permanently protected area?:

Date of implementation: 10-50 years ago

Type of introduction

| Specify input | Unit | Quantity | Costs per Unit (Kshs) | Total costs per input (Kshs) | % of costs borne by land users |

| Labour | |||||

| Establish a contour line | Persons/day | 0.5 | 3.76 | 1.88 | 100.0 |

| Reduce stone size | Persons/day | 0.5 | 3.76 | 1.88 | 100.0 |

| Arranging stones | Persons/day | 0.5 | 3.76 | 1.88 | 100.0 |

| Equipment | |||||

| Mattock | pieces | 1.0 | 18.75 | 18.75 | 100.0 |

| Wheelbarrow | pieces | 1.0 | 20.0 | 20.0 | 100.0 |

| Construction material | |||||

| Stone | no | 1.0 | 1.88 | 1.88 | 100.0 |

| Total costs for establishment of the Technology | 46.27 | ||||

| Total costs for establishment of the Technology in USD | 0.58 | ||||

| Specify input | Unit | Quantity | Costs per Unit (Kshs) | Total costs per input (Kshs) | % of costs borne by land users |

| Labour | |||||

| Repair/Rearrange stone | mandays/acre | 14.0 | 2.5 | 35.0 | 100.0 |

| Total costs for maintenance of the Technology | 35.0 | ||||

| Total costs for maintenance of the Technology in USD | 0.44 | ||||

Such that it hinders mechanisation tractors cannot operate due to the stone line arragement

The operation is labour intensive

Increased food security (the yield near the stoneline is better as compared to the situation that it was before implementation).

Snakes and scorpions