The micro water harvesting technology is part of a larger watershed rehabilitation initiative; It is the most upstream technology used in an integrated approach, including upland rehabilitation (Vallerani), gully erosion control, and revegetation (gully plugs), and downstream local barley agriculture using the ‘Marab’ technology.

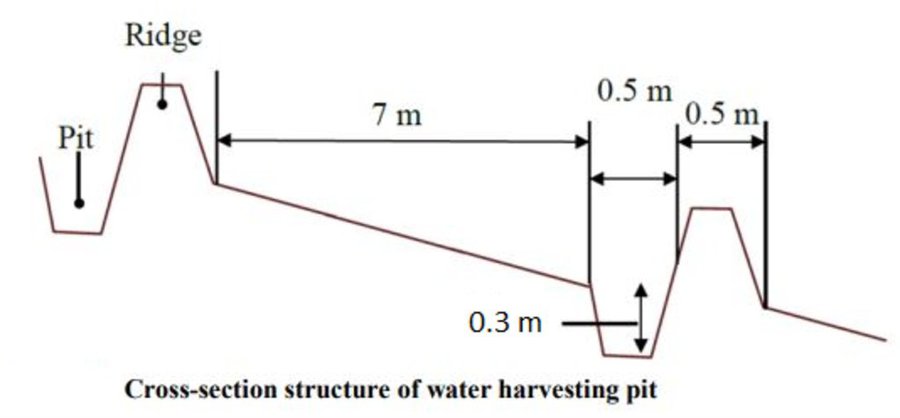

1: Main Elements: The Vallerani tractor plow (Delfino 50 MI/CM) (Gammoh & Oweis, 2011) constructs intermittent water harvesting pits along the contour of terrain and transects the hill slopes at approximately 5-10 m between lines. The local hill slope (at the implementation site) ranges between 2% and 15%. Pit length is adjustable and relates to the speed of the tractor. At the implementation site, pit lengths are around 4.5 m. In the micro water harvesting pits, several native shrub seedlings can be out-planted (at the site, 2 per pit).

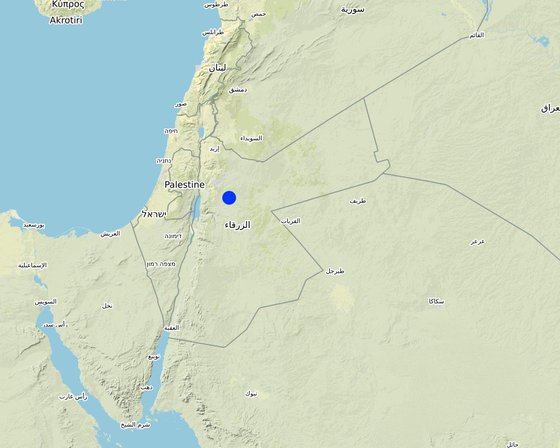

2: Where: This technology is used in a watershed context close to Al Majeddyeh village, located in the Middle Badia zone, approximately 30 km south-east of Amman. The climate is arid and warm (Palmer, 2013). The average annual rainfall is around 130 mm. The natural environment is classified as steppe, Bsh in the köppen classification. The human environment is characterized by agropastoralists. They are semi-nomadic and live in villages around the watershed, for example, Al Majeddyeh village.

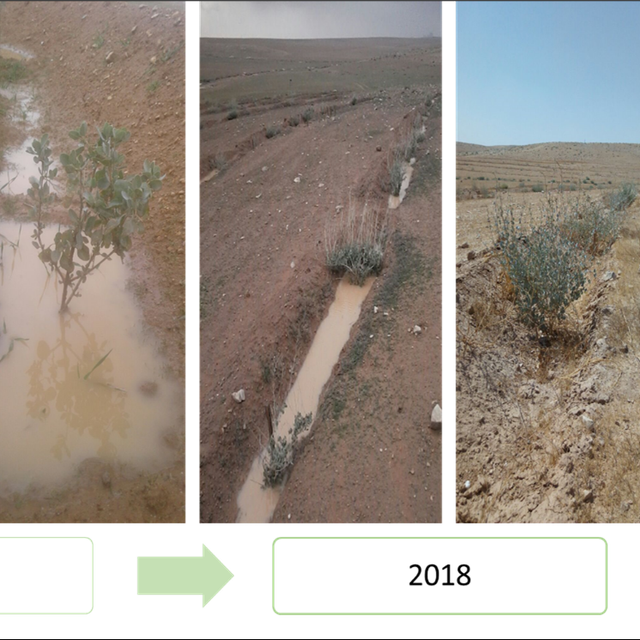

3: The purpose of the technology: Breaking the land degradation cycle by retaining and encouraging deep-infiltration of surface runoff, which supports native vegetation growth. The stored soil moisture boosts the growth of both out-planted shrub seedlings and emerging local seeds towards healthy and resilient vegetation patches. Over time, the plowed pits degrade, but vegetation takes over the dryland hydrological functions of rainfall interception, runoff deceleration, and fostering infiltration. The developing shrubland provides various ecosystem services, predominately fodder for livestock of local agropastoralists.

4: Major activities: 1) Mechanized micro water harvesting establishment through the Vallerani tractor plow. 2) plantation of native seedlings in the pits (2 shrubs per pit at the local site). 3) Manage rangelands through sustainable grazing.

5: Impact: The technology breaks up the degradation cycle, increases soil moisture, and eventually boosts vegetation development and biodiversity. Through retention of runoff, sediments and residues, it decreases erosion and enhances organic carbon storage. It reduces peak surface runoff and thus mitigates flooding. The enhanced biomass supports livestock (grazing) and reduces agricultural inputs required (such as those required for low input barley production).

6: Land users' opinion: Land users evaluate the technology ambivalently. In the short term, landowners are often skeptical, because the rehabilitation requires a recovery time and strict non-grazing/resting for (usually) the first 2 rainy seasons. Thereafter, the rehabilitated lands require sustainable management. Later, after vegetation development, most landowners are convinced of the improvements and understand the economic and environmental value. The acceptance strongly depends on the social and cultural context – many farmers continue preferring the already established barley monoculture, mainly due to lack of sustainable rangeland management options and land ownership. However, well-targeted awareness campaigns can be supportive.

Location: Al Majeddyeh Village, Amman governorates /Al Jiza District/Al Majeddyeh Village, Jordan

No. of Technology sites analysed: single site

Spread of the Technology: evenly spread over an area (30.0 km²)

In a permanently protected area?: Nee

Date of implementation: 2016

Type of introduction

| Species | Count |

| goats | 300 |

| sheep | 50 |

| Specify input | Unit | Quantity | Costs per Unit (USD) | Total costs per input (USD) | % of costs borne by land users |

| Labour | |||||

| Tractor plough operation | Labour Day per hectare | 0.2 | 25.0 | 5.0 | |

| Technical assistance | LD | 0.2 | 50.0 | 10.0 | |

| Seedling planters (local community) | LD | 5.0 | 20.0 | 100.0 | |

| Equipment | |||||

| Tractor + Vallerani Plough (transport & fuel) | Day | 0.2 | 200.0 | 40.0 | |

| Field equipment | Day | 1.0 | 20.0 | 20.0 | |

| Plant material | |||||

| Atriplex Halimus | Seedling | 100.0 | 0.5 | 50.0 | |

| Retama | Seedling | 100.0 | 0.5 | 50.0 | |

| Salsola | Seedling | 100.0 | 0.5 | 50.0 | |

| Other | |||||

| Transportation and storage (e.g. seedlings) | Lumpsum per hectare | 1.0 | 20.0 | 20.0 | |

| Total costs for establishment of the Technology | 345.0 | ||||

| Total costs for establishment of the Technology in USD | 345.0 | ||||