Water harvest [Kenya]

- Creation:

- Update:

- Compiler: Kithinji Mutunga

- Editor: –

- Reviewer: David Streiff

Kunasa maji ya muua yanuyobubugika na kuyuelekeza shambani kwa uzakshaji-Alex R.Adual RSCU/SIDA1996

technologies_1097 - Kenya

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Mutisya Peter Maithya

Daleo's office P.O.Box 42 Makueni Kenya

Kenya

SLM specialist:

Ndengele Michael

Daleo's office P.O.Box 42 Makueni Kenya

Kenya

SLM specialist:

Nguluu Lucas Makau

Daleo's office P.O.Box 42 Makueni Kenya

Kenya

SLM specialist:

SLM specialist:

SLM specialist:

Adunal Alex R.

RELMA/SIDA

Lcraf house P.O.Box 63403 Nairobi, Kenya

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Ministry of Agriculture and Livestock Development of Kenya (MoA) - Kenya1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

21/04/2003

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Water harvest for agricultural production in Asals

2.2 Detailed description of the Technology

Description:

Water harvest enhances extra moisture and reduces risk of crop failure. It can either be external or internal. The activities also reduce runoff/overland flow and soil loss.

Manure and fertilizer improve soil water holding capacity and soil properties.

Appropriate tillage for improvement of infiltration rate of the soil.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Kenya

Region/ State/ Province:

Eastern

Further specification of location:

KiMuiki, Kitise, Mburo, Kwa Kauisi

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

ministry of agriculture and rural development, soil and water conservation branch Nairobi, Kenya

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Main crops (cash and food crops):

Major food crop: Maize

Other: C.peas

Mixed (crops/ grazing/ trees), incl. agroforestry

- Agro-silvopastoralism

Main products/ services:

Major cash crop CT: fruits

Selective felling of (semi-) natural forests for fuelwood purpose

Clear felling of (semi-)natural forests for agricultural production

Forest also for fruits and nuts

Comments:

Major land use problems (compiler’s opinion): Topsoil losses, creation of hardban, soil surface crusting and fertility decline are major problems in areas without SWC.

Major land use problems (land users’ perception): Yield decline and poor quality produce are problems in areas without SWC.

Semi-nomadism / pastoralism: mixed land use type

Mixed: (eg agro-pastoralism, silvo-pastoralism): practiced by few

Other grazingland: semi-intensive grazing: semi-intensive grazing

Grazingland comments: Area closure can not be substituted, stall feeding materials not available. The family leader owns the stock but could fail to meet family needs if the system is not commercialized.

Selective felling of (semi-) natural forests: fuelwood purpose

Clear felling of (semi-)natural forests: for agricultural production

Problems / comments regarding forest use: Some uncontrolled grazing/browsing rather critical tp forest establoshment. Gapping can last long due to rainfall long intervals

Forest products and services: fuelwood, fruits and nuts

Type of cropping system and major crops comments: maize as major crop, followed by tubbers and legumes.

Type of grazing system comments: Area closure can not be substituted, stall feeding materials not available. The family leader owns the stock but could fail to meet family needs if the system is not commercialized.

Constraints of astructure network (roads, railways, pipe lines, power lines): roadside runoff enhances runoff Farming. Isolated trees preserved by traders in Mkt-centres

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- rainfed

Number of growing seasons per year:

- 2

Specify:

Longest growing period in days: 106 Longest growing period from month to month: Mar - Jun Second longest growing period in days: 71 Second longest growing period from month to month: Oct - Dec

3.4 SLM group to which the Technology belongs

- water harvesting

3.5 Spread of the Technology

Comments:

Total area covered by the SLM Technology is 45 m2.

Target-area 485 km^2 inhabited by 6550 farm families and population dynamic 46075.

3.6 SLM measures comprising the Technology

agronomic measures

vegetative measures

- V2: Grasses and perennial herbaceous plants

structural measures

- S3: Graded ditches, channels, waterways

Comments:

Main measures: structural measures

Secondary measures: agronomic measures, vegetative measures

Type of agronomic measures: relay cropping, manure / compost / residues, breaking compacted topsoil

Type of vegetative measures: aligned: -contour, scattered / dispersed, in blocks

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

physical soil deterioration

- Pk: slaking and crusting

- Pi: soil sealing

Comments:

Main type of degradation addressed: Pk: sealing and crusting

Secondary types of degradation addressed: Wt: loss of topsoil / surface erosion, Cn: fertility decline and reduced organic matter content

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

Comments:

Secondary goals: mitigation / reduction of land degradation, rehabilitation / reclamation of denuded land

4. Technical specifications, implementation activities, inputs, and costs

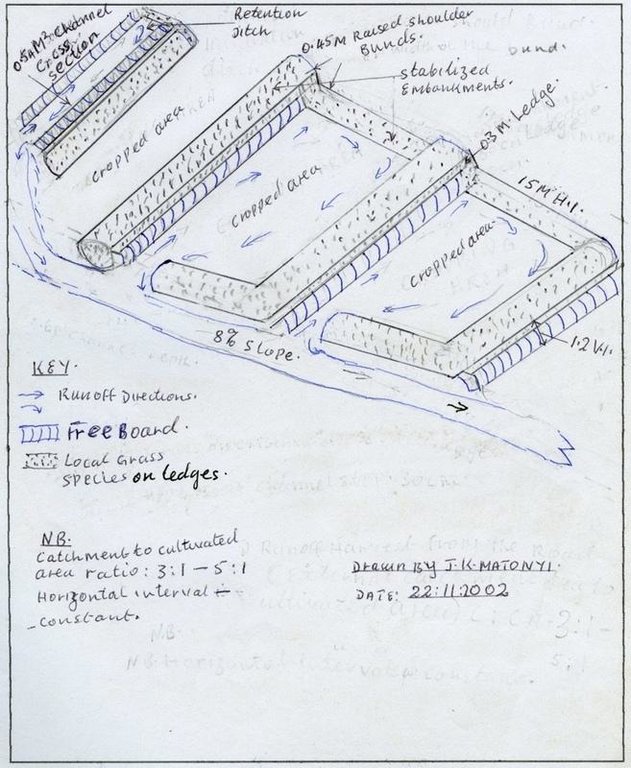

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

technical drawing catchment to cultural area ratio: 3:1 - 5:1 Horizontal interval constant

Makueni district

Date: 22.11.2002

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: high

Main technical functions: water harvesting / increase water supply

Secondary technical functions: increase / maintain water stored in soil, increase in soil fertility

Relay cropping

Material/ species: improved mango trees

Quantity/ density: 124

Remarks: 9 m^2

Manure / compost / residues

Material/ species: FYM/compost

Quantity/ density: 12.5 t/ha

Breaking compacted topsoil

Remarks: appropriate tillage

Aligned: -contour

Vegetative material: G : grass

Vertical interval between rows / strips / blocks (m): 1.2

Spacing between rows / strips / blocks (m): 0.6x0.3

Vertical interval within rows / strips / blocks (m): 15

Width within rows / strips / blocks (m): 1.5

Scattered / dispersed

Vegetative material: T : trees / shrubs

Number of plants per (ha): 40

In blocks

Vegetative material: T : trees / shrubs

Number of plants per (ha): 124

Vertical interval between rows / strips / blocks (m): 9

Spacing between rows / strips / blocks (m): 9x9

Vertical interval within rows / strips / blocks (m): 9

Trees/ shrubs species: Cacia scamea, Accacia albida

Fruit trees / shrubs species: mango, citrus, pawpaw

Grass species: ceuchrus cuharis, erayroster superba

Slope (which determines the spacing indicated above): 8.00%

If the original slope has changed as a result of the Technology, the slope today is (see figure below): 0.00%

Gradient along the rows / strips: 0.20%

Retention/infiltration ditch/pit, sediment/sand trap

Vertical interval between structures (m): 1.2

Depth of ditches/pits/dams (m): 0.6

Width of ditches/pits/dams (m): 1.2

Length of ditches/pits/dams (m): 100

Height of bunds/banks/others (m): 0.45

Width of bunds/banks/others (m): 1.5

Terrace: bench level

Vertical interval between structures (m): 1.2

Spacing between structures (m): 15

Depth of ditches/pits/dams (m): 0.6

Length of ditches/pits/dams (m): 100

Height of bunds/banks/others (m): 0.45

Construction material (earth): earth moving for SWC embankment construction

Slope (which determines the spacing indicated above): 8%

Lateral gradient along the structure: 0.2%

Vegetation is used for stabilisation of structures.

Change of land use type: stock holding capacity of land

4.3 General information regarding the calculation of inputs and costs

Specify currency used for cost calculations:

- US Dollars

Indicate average wage cost of hired labour per day:

1.92

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | grass planting on embankments | Vegetative | after onset of rain |

| 2. | fruits seedling transplanting | Vegetative | october rain |

| 3. | dispersed tree seedlings transplanting | Vegetative | october rain |

| 4. | retention/infiltration ditches | Structural | after crop harvest |

| 5. | Bench terraces | Structural | after crop harvest |

| 6. | external water harvest channels | Structural | before raining season |

| 7. | structure stabilization | Structural | onset of rain |

| 8. | manure/fertilizer application | Structural | after crop harvest |

| 9. | Bush clearing | Management | after grazing |

| 10. | reseeding/grass planting in bare parches | Management | dry season |

| 11. | fodder establishment | Management | rainy season |

| 12. | removal of unwanted shrubs | Management | following rotational sequence |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 296.0 | 296.0 | 100.0 |

| Equipment | Machine use | ha | 1.0 | 32.5 | 32.5 | 100.0 |

| Equipment | Animal traction | ha | 1.0 | 72.3 | 72.3 | 100.0 |

| Equipment | Tools | ha | 1.0 | 385.0 | 385.0 | 100.0 |

| Plant material | Seeds | ha | 1.0 | 76.3 | 76.3 | 100.0 |

| Plant material | Seedligs | ha | 1.0 | 79.5 | 79.5 | 100.0 |

| Fertilizers and biocides | Fertilizer | ha | 1.0 | 58.0 | 58.0 | 100.0 |

| Fertilizers and biocides | Biocides | ha | 1.0 | 47.4 | 47.4 | 100.0 |

| Fertilizers and biocides | Compost/manure | ha | 1.0 | 78.0 | 78.0 | 100.0 |

| Construction material | Stone | ha | 1.0 | 244.0 | 244.0 | 100.0 |

| Total costs for establishment of the Technology | 1369.0 | |||||

Comments:

Duration of establishment phase: 36 month(s)

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | tillaging | Agronomic | before rain / annually |

| 2. | tillaging | Agronomic | on set / seasonally |

| 3. | manure application | Agronomic | dry season / annually |

| 4. | grass cutting and gapping | Vegetative | onset of rain /twice per season |

| 5. | prunning and trimming | Vegetative | after every harvest /annual |

| 6. | pollading and copsing | Vegetative | when intended /after several years |

| 7. | retention/infiltration | Structural | before onset of rain/seasonally |

| 8. | ditch cleaning | Structural | before onset of rain/anually |

| 9. | Bench terraces repairing | Structural | before onset of rain/when necessary |

| 10. | Water channel cleaning/repairing | Structural | dry period/seasonally |

| 11. | grass cutting for stall feedinf | Management | rainy season / at maturity stage |

| 12. | gapping | Management | rainy season / seasonally |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 98.0 | 98.0 | 100.0 |

| Equipment | Animal traction | ha | 1.0 | 72.3 | 72.3 | 100.0 |

| Plant material | Seeds | ha | 1.0 | 67.3 | 67.3 | 100.0 |

| Plant material | Seedlings | ha | 1.0 | 55.7 | 55.7 | 100.0 |

| Fertilizers and biocides | Fertilizer | ha | 1.0 | 44.2 | 44.2 | 100.0 |

| Fertilizers and biocides | Biocides | ha | 1.0 | 21.5 | 21.5 | 100.0 |

| Construction material | Earth | ha | 1.0 | 244.0 | 244.0 | 100.0 |

| Total costs for maintenance of the Technology | 603.0 | |||||

Comments:

Machinery/ tools: oxplough, oxcart, hoe, sprayer, shovel, wheelbarrow

The above costs were calculated in cost per qm

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Factors affecting the costs include hard ground at SWC peak period, labour, slope, catchment area, channel size and source of income

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

350.00

Agro-climatic zone

- semi-arid

- arid

semi-arid: LGP-70-180

arid: LGP-60-120

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Altitudinal zone: about 1000 m a.s.l. average

Landforms: Footslopes 8-16% slope and valley floors 2-8% slope

Slopes on average: Moderate = 6.5 % and rolling = 12 %

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil depth on average: shallow = 35 cm average and moderately deep = 65 cm average

Soil texture: Coarse/light = degradable/erodable and medium is common in the division

Soil fertility is medium in newly opened lands but fertility depletes quickly and is therefore also low.

Topsoil organic matter is medium on newly opened land and low after several years of cultivation.

Soil drainage / infiltration is medium with regular improvement, but there is also top soil crusting and therefore drainage becomes poor,

Soil water storage capacity is low during long duration of rainfall intervals and medium (effectiveness not realistic).

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

- average

Level of mechanization:

- manual work

- animal traction

Indicate other relevant characteristics of the land users:

Population density: 50-100 persons/km2

Annual population growth: 3% - 4%

20% of the land users are rich and own 20% of the land (prestige).

35% of the land users are average wealthy and own 30% of the land (improved living standard).

25% of the land users are poor and own 20% of the land (for subsistance).

Off-farm income specification: Most of youth seek for off-farm employment. Others due to lack of employment engage on trading as small holders.

Level of mechanization: Around 75 % use animal traction and manual labour is especially used for weeding

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Comments:

Average area of land owned or leased by land users applying the Technology: Also 0.5-1 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

- individual, titled

Land use rights:

- individual

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

Extra output 50%

production area

Comments/ specify:

given area reduced by 14%

Income and costs

farm income

Comments/ specify:

Extra income 27.5%

workload

Comments/ specify:

requires high labour costs

Socio-cultural impacts

community institutions

Comments/ specify:

in capacity building

SLM/ land degradation knowledge

Comments/ specify:

to land user

Ecological impacts

Water cycle/ runoff

surface runoff

Quantity before SLM:

32

Quantity after SLM:

14

excess water drainage

Comments/ specify:

risking occasion

Soil

soil moisture

Comments/ specify:

external WH.

soil loss

Quantity before SLM:

20

Quantity after SLM:

10

Comments/ specify:

WH combination

6.2 Off-site impacts the Technology has shown

reliable and stable stream flows in dry season

Comments/ specify:

irrigation potential reduced

downstream flooding

Comments/ specify:

rainfall runoff trapped

downstream siltation

Comments/ specify:

silt retained on cropland

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

6.5 Adoption of the Technology

- 1-10%

If available, quantify (no. of households and/ or area covered):

630 household covered an area of 9%

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 90-100%

Comments:

630 land user families have adopted the Technology without any external material support

Comments on spontaneous adoption: estimates

There is a moderate trend towards spontaneous adoption of the Technology

Comments on adoption trend: Pressure on daily personal needs. No other sources of income yet the rainfall is not reliable in ASALS.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

induces the technique of implementation How can they be sustained / enhanced? land users be aquidance with the technology and its importance. |

|

land users acquires more grass for stall feeding. How can they be sustained / enhanced? introduction of intensive grazing system. |

|

reduces floods of heavy storms downsteram. How can they be sustained / enhanced? Proper tillage to curb soil crusting and hardban. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

water harvest increases farm production and reduces risks of crop failure. How can they be sustained / enhanced? To stabilize SWC structure embankments, desilt channels and retention ditches. |

|

Improvement in infiltration rate and moisture holding capacity. How can they be sustained / enhanced? Use of manure, organic matter, inorganic fertlizer and appropriate tillage. |

|

Reduces soil, fertility, runoff and overland flow losses How can they be sustained / enhanced? Maximum adaptability of the SWC technology to ustain high production level. |

|

Enhanced vegetative cover for moisture retention. How can they be sustained / enhanced? Intercropping, mulching and repairing where needed. |

|

Reduces erosion by wind and other land degradation. How can they be sustained / enhanced? Appropriate stocking rate andd replanting trees and grass. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| consumes a lot of time to implement the technology | the land user awareness of the importance of the activity. |

| Technology area resists a direct grazing | to mitiate stall feeding |

| the technology design is beyond the farmers knowledge. | continuous interaction with SWC specialists. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Land area reduced by SWC structures constructed. | Use of certified seeds, manure and fertilizer. |

| soil fertility is interfered with. | more manure and organic matter use. |

| High labour cost requirement to implement the technology. | Introduced source of smooth loan and policy for ASALS. |

| Risk of water logging where soil drainage is unaimable. | acquired knowledge of different soil types and applicable technology and system. |

| cost-benefit return can last long to be realized. | to maintain record for both, implementing cost and income from the given area (SWC area) |

7. References and links

7.2 References to available publications

Title, author, year, ISBN:

SWC manual for Kenya by D:B: Thomas. 1997.

Available from where? Costs?

Mard Kenya, free

Title, author, year, ISBN:

SWC technology Dev. in ASAL by Kithinji Mutunga

Available from where? Costs?

SWC branch, free

Title, author, year, ISBN:

SC in Kenya, Carl G.Wenner. 1984.

Available from where? Costs?

Aici, free

Title, author, year, ISBN:

ony superb DXE-180 video

Available from where? Costs?

Mard Kenya, free

Title, author, year, ISBN:

The sun will still rise

Available from where? Costs?

Mard Kenya, free

Title, author, year, ISBN:

Run off a friend or a foe

Available from where? Costs?

Mard Kenya, free

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules