Contour band combined with Sessebania sessebani, beans, manure and trashlines in banana production. [Tanzania, United Republic of]

- Creation:

- Update:

- Compiler: Godfrey Baraba

- Editor: –

- Reviewers: Ursula Gaemperli, Fabian Ottiger

Fanya juu fanya chini na mbaazi katika uzalishaji wa ndizi.

technologies_1208 - Tanzania, United Republic of

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

SLM specialist:

Nkuba Julitha

Bukoba District Council

Tanzania, United Republic of

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Bukoba district council (Bukoba district council) - Tanzania, United Republic ofName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Missenyi District Council (Missenyi District Council) - Tanzania, United Republic of1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

17/06/2014

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

Nee

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Is the digging of a farrow measured 0.6 width by 0.6 depth along the contour line and embankment of the excavated soils on the upper side at the slope <2% and upper side at the slope >5% in the banana, beans inter croped fields.

2.2 Detailed description of the Technology

Description:

Contour bund combined with Sessbania sesseban, beans and manure technology in banana production is the digging and excavation of a 60cm wide by 60co deep furrow, plated Sessbania sessban along the contour bund, application of farm yard manures in a 30cm deep by 60 cm wide furrow at 30cm from the banana stool and plating beans in the space between bunds. The technology is applied on Perennial (non-woody) cropping system, supported with rain fed to prevent and mitigate land degradations. The production mode is mixed (subsistence and commercial. The technology impact should be observed on controlled soil erosion by water, reduced declining soil fertility, and increased water infiltration. To implement this technology, a total of US$ 100.41 establishment costs per hectare and US% 1,076.47 maintenance costs per hectare per year according to the introduction of the technology in 2012 By TAMP –Kagera. Small ruminants rearing are the supportive measures of the technology.

Purpose of the Technology: The major purpose of the technology is land degradation prevented in 50 ha, crop and livestock production increased by 10% to contribute on food security and livelihood improvement with a SLM. Technically the technology should control of raindrop splash, control of dispersed runoff: retain / trap, reduction of slope length, stabilisation of soil (eg by tree roots against land slides), increase in organic matter, increase in nutrient availability (supply, recycling) and increase of water infiltration.

Establishment / maintenance activities and inputs: The establishment activities includes:- First, identification and demarcation of contour line done manually using simple tool (A-frame); this is done in May. Second is the digging of a 0.6m width and 0.6m depth furrow, excavation the soils and place them on the upper side (at the smaller slope) and lower side (at the bigger slope) along the contour using chisel hand hoes, fork hand hoes spades and mattock; this is done in June. Third is to drill two rows of Sessbania sesban seeds, spaced 0.3 m between the rows; this is done in late September. Fourth is the thinning of Sessbania sesban seedlings at the average space of 15cm done manually; this is done when the seedling is at the height of. The maintenance activities include; First is to weed the whole field done manually using local made tools (kahosho); this is done twice in January to February and June to August. Second is to apply farm yard manures in the furrow of 0.3 m deep by 0.6m wide cultivated 0.60 m from the banana stool and facing the granddaughter sucker; this is done early July. Third is desuckering and detrushing of banana stools using local made tools (kihosho and rwabyo) and machete; this is done twice (February and September).Fourth is to plant beans done manually using local made tool (kahosho; this is done in March and September. Fifth is the harvesting of beans and hauling done manually; this is done twice (June and early February). Sixth is cleaning of the furrow done manually using spades; this is done twice at the end of rain seasons (January and December). Finally, harvesting of banana and Sessbania sessban is done according to the market demand.

Natural / human environment: The physical environment is characterized of sub humid climatic zone, 750-1000 mm rain falls, 1000-1500 m.a.s.l, hill slopes land form with gentle slope. The soil texture is medium (loam), Soil fertility is medium, topsoil organic matter is medium (1-3%) and soil drainage/infiltration is medium. The soil water storage capacity is medium, ground water table is 5 - 50 m, availability of surface water is medium and water quality is poor drinking water. This technology is tolerant of seasonal rainfall decrease, droughts / dry spells while sensitive to heavy rainfall events (intensities and amount). The land users applying the technology are individual / household, Small scale land users, common / average land users. The Land ownership is communal / village, individual, not titled . The Land use rights is communal (organised), and/or individual. The water use rights is open access (unorganised). The relative level of wealth is categorized as rich, which represents 4% of the land users and own 34% of the total area. The average category, which represents 64% of the land users own 64% of the total area. The poor category, which represents 32% of the

land users owns 2% of the total area.

2.3 Photos of the Technology

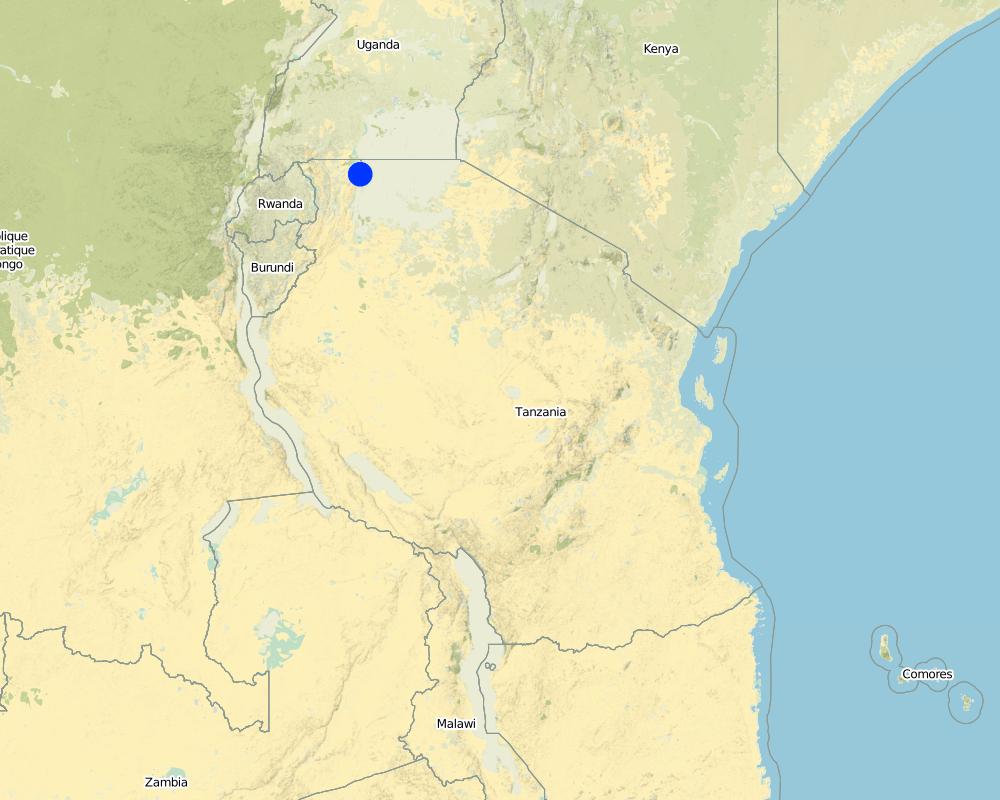

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Tanzania, United Republic of

Region/ State/ Province:

Tanzania

Further specification of location:

Bukoba District council

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

The technology introduce by TAMP -Kagera using FFS in 2012.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Perennial (non-woody) cropping

- Tree and shrub cropping

Main crops (cash and food crops):

Major cash crop: Coffee, Beans, Avocado

Major food crop: Maize, banana

Others: Bambara nuts and sweet potatoes, mangos

Comments:

Major land use problems (compiler’s opinion): The majoe land use problems related to soil, water and vegetation in the area were soil erosion, low water soil infiltration and declining soil nutrients.

Major land use problems (land users’ perception): Moisture stress and low productivity.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- rainfed

Number of growing seasons per year:

- 2

Specify:

Longest growing period in days: 120, Longest growing period from month to month: September to December Second longest growing period in days: 90 Second longest growing period from month to month: March to May

3.4 SLM group to which the Technology belongs

- agroforestry

- integrated soil fertility management

3.5 Spread of the Technology

Comments:

Total area covered by the SLM Technology is 0.002 m2.

The technology applied in a 0.5 acre as FFS site in the host farmer land one year past. However, the period is too short for adoption process to take place.

3.6 SLM measures comprising the Technology

agronomic measures

- A1: Vegetation/ soil cover

- A2: Organic matter/ soil fertility

vegetative measures

- V2: Grasses and perennial herbaceous plants

structural measures

- S2: Bunds, banks

Comments:

Type of agronomic measures: temporary trashlines, legume inter-planting, manure / compost / residues

Type of vegetative measures: aligned: -contour

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

Comments:

Main causes of degradation: soil management (Cultivation along the slope), crop management (annual, perennial, tree/shrub) (continous harvesting perennial crops without fertilizing the soil.), change of seasonal rainfall (seasonal rainfall is unpredictable now days.), droughts (The area experienced a drought period averaged 155 days.), population pressure (Increased population resulted presure on land, while the responce is cultivation in marginal lands.), poverty / wealth (Poor farmers can not afford to invest in land conservation due to its nature of longterm investment.), education, access to knowledge and support services (Most of farmers received primary education where land concervation is not taught. Further more there is inadequate staffing of Agriculture advisors.)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.2 Technical specifications/ explanations of technical drawing

Technical knowledge required for field staff / advisors: low (The technology principles are taught at colleges. Hence retraining should complement this knowledge to accomplish implementation.)

Technical knowledge required for land users: low (The technology is easy to apply, only sensitization can complement the awareness to implement the technology.)

Main technical functions: control of raindrop splash, control of dispersed runoff: retain / trap, reduction of slope length, stabilisation of soil (eg by tree roots against land slides), increase in organic matter, increase in nutrient availability (supply, recycling,…), increase of infiltration

Temporary trashlines

Material/ species: Farm product residue, banana dry leaves and pseudostems.

Remarks: Spread across the slope at 5cm depth.

Legume inter-planting

Remarks: dibling scatered in the space between the bunds,

Manure / compost / residues

Material/ species: cow dunng

Remarks: mixed in the furrow measured 30cm depth, 60cm toward the grand daughter banana plant.

Aligned: -contour

Vegetative material: O : other

Number of plants per (ha): 1667

Vertical interval within rows / strips / blocks (m): 0.15

Width within rows / strips / blocks (m): 0.3

Other species: Sessebania sesseban

Bund/ bank: level

Spacing between structures (m): 6

Depth of ditches/pits/dams (m): 0.6

Width of ditches/pits/dams (m): 0.6

Length of ditches/pits/dams (m): 35

Height of bunds/banks/others (m): 0.6

Width of bunds/banks/others (m): 0.6

Length of bunds/banks/others (m): 35

Construction material (earth): soils

Slope (which determines the spacing indicated above): 3%

Vegetation is used for stabilisation of structures.

4.3 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Tshs

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

1700.0

Indicate average wage cost of hired labour per day:

1.76

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | To plant sessebania seeds by drilling along the contour bunds, | Vegetative | March |

| 2. | To thin extra seedling and allow a 30cm between plants by 30cm between rows. | Vegetative | irregular |

| 3. | To demarcate the contour line | Structural | August |

| 4. | To dig and excavate soils to make bunds | Structural | |

| 5. | Purchase tools | Management |

Comments:

Lifespan of tools: 5 years

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | plant sessebania seeds by drilling along the contour bunds | Mandays | 1.0 | 1.76 | 1.76 | 100.0 |

| Labour | thin extra seedling and allow a 30cm between plants by 30cm between rows | Mandays | 1.0 | 1.76 | 1.76 | 100.0 |

| Labour | demarcate the contour line | Mandays | 1.0 | 1.76 | 1.76 | 100.0 |

| Labour | dig and excavate soils to make bunds | Mandays | 1.0 | 1.76 | 1.76 | 100.0 |

| Equipment | Tools | pieces | 4.0 | 2.91 | 11.64 | 100.0 |

| Plant material | Seeds | kg | 0.9 | 0.588888 | 0.53 | |

| Total costs for establishment of the Technology | 19.21 | |||||

Comments:

Duration of establishment phase: 15 month(s)

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | To Weeding the entire field prior nonseasonal. | Agronomic | June to september & february |

| 2. | To apply manure in a 60 x60 farrow along the daughter plant | Agronomic | october |

| 3. | desuckering and detrushing banana plants | Agronomic | September & February |

| 4. | To plant (dibbling) beans in the space between bunds. | Agronomic | October and March |

| 5. | To harvest seeds | Vegetative | |

| 6. | To prune branches for goat feeds | Vegetative | irregular |

| 7. | To remove soil sediments in the farrow | Structural | june and february |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Weeding the entire field prior nonseasonal. | Mandays | 6.0 | 1.76 | 10.56 | 100.0 |

| Labour | apply manure in a 60 x60 farrow along the daughter plant | Mandays | 10.0 | 1.76 | 17.6 | 100.0 |

| Labour | desuckering and detrushing banana plants | Mandays | 3.0 | 1.76 | 5.28 | 100.0 |

| Labour | lant (dibbling) beans in the space between bunds | Mandays | 3.0 | 1.76 | 5.28 | 100.0 |

| Plant material | Seeds | kg | 30.0 | 0.706 | 21.18 | 100.0 |

| Fertilizers and biocides | Compost/manure | tons | 1.5 | 29.413333 | 44.12 | |

| Other | Labour: harvest seeds | mandays | 5.0 | 1.76 | 8.8 | 100.0 |

| Other | Labour: prune branches for goat feeds | mandays | 5.0 | 1.76 | 8.8 | 100.0 |

| Other | Labour: remove soil sediments in the farrow | mandays | 3.0 | 1.76 | 5.28 | 100.0 |

| Total costs for maintenance of the Technology | 126.9 | |||||

Comments:

The costs were calculated on plant population (banana 1111) per hector as well as length of the bund (sebania spps 6762)

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The most determinate factor is labour (US$ 308.25/799.92).

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- sub-humid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

- fine/ heavy (clay)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility: Medium and low

Soil drainage/infiltration: Medium

Soil water storage capacity: Medium

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

poor drinking water (treatment required)

Comments and further specifications on water quality and quantity:

Availability of surface water: Medium (In dry season all ponds dry of while in rain season some ponds overflows)

Water quality: Poor drinking water (treatement required, surface water during rainy season and ground (spring water) during dry season)

5.5 Biodiversity

Species diversity:

- medium

Comments and further specifications on biodiversity:

Earthworms, ants, grasshoppers etc.

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial

Off-farm income:

- less than 10% of all income

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Indicate other relevant characteristics of the land users:

Population density: 10-50 persons/km2

Annual population growth: < 0.5%

Relative level of wealth: rich, average, poor

4% of the land users are rich and own 34% of the land.

64% of the land users are average wealthy and own 64% of the land.

32% of the land users are poor and own 2% of the land.

Off-farm income specification: The off-farm income is less than 10% for land users who applied the technology because the opportunity cost of implementing the technology is absconded from off-farm activites.

Market orientation: Mixed (banana, beans and maize are for subsistence and commercial while coffee if for commecial purely)

Level of mechanization: Manual work (using handoes and forkhoess)

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

Comments:

Average area of land owned or leased by land users applying the Technology:

< 0.5 ha: Poor

0.5-1 ha: Majority own average of 0.75 ha of cropland, thow few posess established forest as well as rangeland (rweya).

1-2 ha: Rich

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

- individual, not titled

Land use rights:

- communal (organized)

- individual

Water use rights:

- open access (unorganized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

5

Quantity after SLM:

9

Comments/ specify:

banana and beans

fodder production

Quantity before SLM:

0

Quantity after SLM:

2

Comments/ specify:

dessebania tree branches.

fodder quality

Quantity before SLM:

14

Quantity after SLM:

21

Comments/ specify:

Digestable Crude Protein.

animal production

Quantity before SLM:

0.05kg

Quantity after SLM:

0.075kg

Comments/ specify:

liveweight gain per goat kid/annum

Income and costs

expenses on agricultural inputs

Comments/ specify:

manures costs

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Increased banana and beans productivity can sustainthe house hold consuption requirement as well as selling excess to access source of animal protein and utilise a balanced diety for prosperous health.

health situation

community institutions

SLM/ land degradation knowledge

Improved livelihoods and human well-being

Comments/ specify:

It is very difficult to identify the contribution to improved livelihood and well-being of such juvenile technology in the area.

Ecological impacts

Water cycle/ runoff

surface runoff

Comments/ specify:

trashlines

evaporation

Comments/ specify:

trashlines and beans crops

Soil

soil moisture

Comments/ specify:

use of trshlines and beans as crop cover

soil cover

Comments/ specify:

beans

soil loss

Comments/ specify:

sedments collcted if furrows

nutrient cycling/ recharge

Comments/ specify:

sessebania

soil organic matter/ below ground C

Comments/ specify:

manures

Biodiversity: vegetation, animals

biomass/ above ground C

Comments/ specify:

Trashline

beneficial species

6.2 Off-site impacts the Technology has shown

damage on public/ private infrastructure

Comments/ specify:

run-off water retined by bund in the field insteady of running along the roadsides.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Comments:

The technology is tolerant of seasonal rainfall decrease, droughts / dry spells while sensitive to heavy rainfall events (intensities and amount). In case of sensitivity spillways on bands is considered to be the best modification.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

very positive

Comments:

The short term returns (annual farm income) is slightly negative compared with establishment costs while the long term returns anticipated being very positive in the long term returns ( cumulative farm income) due to reduced establishment costs.

The short term return is slightly positive compared with maintenance costs while the long-term return is anticipated to be very positive due increased land productivity.

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

9% of land user families have adopted the Technology with external material support

13 land user families have adopted the Technology with external material support

Comments on acceptance with external material support: 3 participants as host farmer provided with farm inputs during FFS.

13 land user families have adopted the Technology without any external material support

Comments on spontaneous adoption: No body has adopted, because the technology has been introduce in late 2012.

There is no trend towards spontaneous adoption of the Technology

Comments on adoption trend: The technology implementation is still young to be adopted.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Appropriate technology in the sense of intensive labour application. |

| Supportive measures very diversity. |

| Low establishment costs, only structure measures. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Trushlines on can not reduce the moisture strees completely in the drought area as such. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules