Biogas [Botswana]

- Creation:

- Update:

- Compiler: Sebego Reuben

- Editor: –

- Reviewer: Fabian Ottiger

Gase ya Boloko (Setswana)

technologies_1521 - Botswana

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Mulale Kutlwano

P/bag UB 00704 Gaborone

Botswana

SLM specialist:

Chanda Raban

University of Botswana

P/bag UB 00704 Gaborone

Botswana

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

DESIRE (EU-DES!RE)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

University of Botswana (University of Botswana) - Botswana1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

19/02/2009

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Production of methane gas from cow-dung for use in house-hold cooking, heating and lighting in order to reduce fire wood demand

2.2 Detailed description of the Technology

Description:

Biogas plant: The biogas plant can be constructed in several ways as long as it can provide a medium for the biological material be digested. Biogas is the name given to the gas that is produced during the decomposition of some organic waste specifically to produce methane gas. The gas is then captured in a storage tank (on site) to be used for household energy needs. In many parts of the world where this technology is used (including Botswana) the most common form of input material is cow dung making it more appropriate for rural environments.

Purpose of the Technology: Advantages: the technology offers two major advantages; first, at every level of use i.e. individual or institutional, savings in terms of energy is realized. The only costs that are borne are at installation, otherwise input of cow dung has a minimal cost of collection (if any at all). The second advantage is that there is reduced usage of fuel wood which translates into less cutting down of trees leading to reduced deforestation and degradation of land. A disadvantage is the initial investment which is significant for poor farmers.

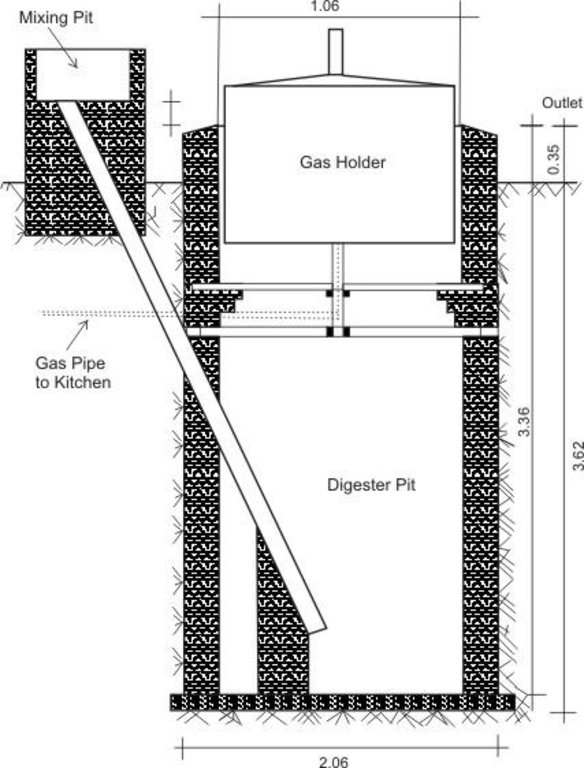

Establishment / maintenance activities and inputs: Construction of the biogas plant: construction of the plant consists of three main chambers: namely, the Digester pit where all the microbiological reactions or decomposition of the material takes place. The digester has to be built to be air-tight with the released gas only escaping into the gas holder. The gas holder is connected to the digester by way of a pipe. Its main purpose is to collect all the gas that has been fermented. The mixing pit is the input chamber where the dung is mixed with water and fed into the digester. The amount and quality of water required for this is no constraint, even in this water stressed area. Construction the biogas plant has to be done according to specifications. A technical drawing of the plant is shown on page 3. The purpose of the technology is to use it for house-hold energy (for cooking, lighting and running appliances).

Natural / human environment: In Botswana the technology was introduced by the Rural Industries Innovation Center which is a government funded research institution. Despite the existence of this company for many years, the uptake has been very low due to poor marketing and extension services and lack of financial assistance to poor farmers.

Biogas is suitable either for a farm, cattle post or rural setting where the inputs (cow dung) are easily available. But there are possibilities of experimenting with other bio-degradable materials in major centres where cow dung is not readily available.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Botswana

Region/ State/ Province:

Southern District

Further specification of location:

Kanye village

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- 10-50 years ago

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

The technology is promoted by a government funded NGO, but has its origins outside the country

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

- conserve ecosystem

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Mixed (crops/ grazing/ trees), incl. agroforestry

- Agro-silvopastoralism

Main products/ services:

Major cash crop seasonal cropping:

Major food crop seasonal cropping:

Major other crops seasonal cropping:

Main products semi-nomadism / pastoralism: Beef cattle, goats, sheep, donkeys, chicken

Main products ranching: Beef cattle

Forest products and services: fuelwood, fruits and nuts, grazing / browsing

Comments:

Major land use problems (compiler’s opinion): Overgrazing of the commons, droughts, saline water and over-harvesting of fuelwood for cooking, heating leading to deforestation and land degradation

Major land use problems (land users’ perception): Overgrazing of the commons, droughts, saline water and over-harvesting of fuelwood for cooking, heating leading to deforestation and land degradation.

Grazingland comments: Biogass technology is not applied in the Boteti area at the moment, only at DESIRE test site.

Selective felling of (semi-) natural forests: specific tree species are felled for fuelwood even though people are supposed to take only fallen-dead wood

Type of cropping system and major crops comments: Mixed cropping is the traditional practice but government extension advice promotes monocropping which the majority find expensive and risky.

Type of grazing system comments: Biogass technology is not applied in the Boteti area at the moment, only at DESIRE test site.

Constraints of settlement / urban

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- rainfed

Comments:

Water supply: Also post-flooding

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 179 Longest growing period from month to month: Oct - Mar

Livestock density (if relevant):

1-10 LU /km2

3.4 SLM group to which the Technology belongs

- energy efficiency technologies

3.5 Spread of the Technology

Comments:

Total area covered by the SLM Technology is 0 m2.

This technology is basically on a point location, even though it is to benefit a wider area in terms of conservation

3.6 SLM measures comprising the Technology

structural measures

- S11: Others

management measures

- M2: Change of management/ intensity level

Comments:

Main measures: management measures

3.7 Main types of land degradation addressed by the Technology

biological degradation

- Bc: reduction of vegetation cover

- Bs: quality and species composition/ diversity decline

Comments:

Main type of degradation addressed: Bc: reduction of vegetation cover, Bs: quality and species composition /diversity decline

Main causes of degradation: deforestation / removal of natural vegetation (incl. forest fires) (harvesting of fuelwood for cooking, sometimes live trees are harvested.), land tenure (Area is communal grazing land)

Secondary causes of degradation: over-exploitation of vegetation for domestic use (Trees are cut for bush fences), droughts (The study area is prone to droughts), poverty / wealth ((lack of alternative livelihood sources))

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- restore/ rehabilitate severely degraded land

Comments:

Secondary goals: prevention of land degradation, mitigation / reduction of land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

The diagram shows the technical layout of a biogas plant; showing the position of the main components: Digester, Gas holder, Mixing pit, and outlet. Cow dung & or kitchen waste (except bones) is mixed with water to form a sludge. This sludge is fed into the digester pit where decomposition and fermentation takes place. As the sludge ferments, methane gas is produced. Methane is a combustible gas and can therefore be used for cooking and lighting. Specially designed gas stoves and lanterns may be required as the gas would not be purified and hence ‚thicker‘ than commercially produced gasses. However, the design can include a water filled pipe bend (u shaped) between the gas holder and outlet pipe. The water in this pipe would help to purify the gas before it is fed to the household appliances. The gas holder tank floats in water, through which the gas bubbles escape and methane gas collects into the floating tank. An outlet through which decomposed material leaves the plant is necessary. Old sludge would float and be removed through this opening (Diagram drawn by G. Koorutwe, Department of Environmental Science, University of Botswana).

Location: Mopipi. Boteti Sub-District

Date: 05/10/11 (revised)

Technical knowledge required for field staff / advisors: high (Skilled technician is needed for installation)

Technical knowledge required for land users: moderate

Main technical functions: reduction of wood exploitation

Secondary technical functions: promotion of vegetation species and varieties (quality, eg palatable fodder), enhancement of tree growth

Structural measure: Digestion pit

Depth of ditches/pits/dams (m): 3.38

Width of ditches/pits/dams (m): 2.06

Structural measure: Gas holder

Depth of ditches/pits/dams (m): 2

Width of ditches/pits/dams (m): 1.6

Construction material (other): bricks, pipes, cement, iron sheets

Change of land use practices / intensity level: Use of biogass for cooking would lead to reduced cutting of wood for cooking

4.3 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Pula

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

6.5

Indicate average wage cost of hired labour per day:

1.08

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Construction | Management | N/A |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | Tank | 1.0 | 198.0 | 198.0 | 100.0 |

| Equipment | Tank | Tank | 1.0 | 615.0 | 615.0 | 100.0 |

| Equipment | Bricks | Tank | 1.0 | 77.0 | 77.0 | 100.0 |

| Equipment | Cement | Tank | 1.0 | 123.0 | 123.0 | 100.0 |

| Equipment | Plumbing material | Tank | 1.0 | 154.0 | 154.0 | 100.0 |

| Construction material | Earth | Tank | 1.0 | 31.0 | 31.0 | 100.0 |

| Total costs for establishment of the Technology | 1198.0 | |||||

Comments:

Duration of establishment phase: 0.5 month(s)

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Filling up with cow dung and water | Management | 1 Day |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | Cow dung | Tank | 1.0 | 33.0 | 33.0 | 100.0 |

| Total costs for maintenance of the Technology | 33.0 | |||||

Comments:

Costs were calculated for labour and material based on the real cost of construction at the Mopipi Site.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Material, labour and equipment used in construction are the most determining factors affecting the costs (installation cost is US$ 1198).

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Seasonal summer rains, approx six months dry (LPG = 75-179)

Agro-climatic zone

- semi-arid

Thermal climate class: subtropics. Sub-tropical climate. Semi-arid with dry winters (LPG=75-179 days).

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Altitudinal zone: 501-1000 m a.s.l. (Part of the Makgadikgadi basin)

Slopes on average: Flat (ranked 1, mainly low lying land of lucrustrine (pans) formation) and gentle (ranked 2, gently sloping (plains))

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

- fine/ heavy (clay)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil depth on average: Shallow (ranked 1, generally soils are 40cm deep, underneath is a calcrete layer at about 40cm deep) and deep (ranked 2, some sandy area away from pans e.g. the Gidikwe Ridge )

Soil texture: Coarse/light (ranked 1, away from pans/river/flood plain = main soil type) and fine/heavy (ranked 2, sticky when wet in the depression)

Soil fertility: Low (ranked 1, sandy areas (Arenosols)) and medium (ranked 2, in flood plains of the Boteti river)

Topsoil organic matter: Low (ranked 1, low on sandy areas/soils) and topsoil organic matter (ranked 2, on the flood plains for molapo farming)

Soil drainage/infiltration: Good (ranked 1, very good on sandy soils) and medium (ranked 2, flood plains are medium)

Soil water storage capacity: Very low (ranked 1, on sandy soils) and medium (ranked 2, on flood plains)

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

poor/ none

Water quality (untreated):

poor drinking water (treatment required)

Comments and further specifications on water quality and quantity:

Ground water table: >50m (ranked 1, for Boreholes) and 5-50 m (ranked 2, wells in the Boteti River bed)

Availability of surface water: poor/none (dry season-unreliable river flow/rainfall)

Water quality (untreated): Poor drinking water (treatement required, salty water in most areas, ranked 1) and unusable (sometimes too salty even for livestock consumption, ranked 2)

5.5 Biodiversity

Species diversity:

- high

Comments and further specifications on biodiversity:

Biodiversity: High (several game reserves (protected areas) nearby, ranked 1) and low (grazing areas with arable agriculture, ranked 2)

5.6 Characteristics of land users applying the Technology

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

- very rich

Individuals or groups:

- individual/ household

Level of mechanization:

- animal traction

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly Leaders / privileged

Difference in the involvement of women and men: There is no difference, as this is mainly a family thing or institutioanal like in schools and community halls

Population density: < 10 persons/km2

Annual population growth: 2% - 3%

10% of the land users are very rich and own 50% of the land (Cattle farmers).

60% of the land users are average wealthy and own 30% of the land (Most inhabitants).

30% of the land users are poor and own 20% of the land (Subsistance farm).

Off-farm income specification: Saves money for buying commercial gas and electric power. Helps conserve the forests. Limited off-farm income opportunities for everyone including non-adopters of the technology.

Level of mechanization: Animal traction (mostly donkeys for draught power)

Market orientation of annual cropping production system: Mixed (subsistence/commercial) Could be used/produced for domestic and commercial purposes.

Market orientation of grazing land production system: Subsistence and commercial/market

Market orientation of forest production system: Mixed (subsistence/commercial) in both cases use of biogas is approppriate

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- large-scale

Comments:

Average area of land owned or leased by land users applying the Technology on grazing land

1000-10000 ha (ranked 1, cattle farmers in ranches and cattle posts)

15-50 ha (ranked 2, subsistence farmers)

Average area of land owned or leased by land users applying the Technology on cropland:

50-100 ha (ranked 1)

2-5 ha (ranked 2, on average)

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

- individual, not titled

Land use rights:

- open access (unorganized)

- individual

Water use rights:

- communal (organized)

- individual

Comments:

The SLM can be used by anybody - not specified to any group. Dual grazing rights is a problem (private ranchers can also use the commons).

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

Assuming large scale removal of dung, there could be reduction in animal manure available for crop production

energy generation

Income and costs

expenses on agricultural inputs

Comments/ specify:

As farmers would have to purchase fertilizer as animal manure becomes scarce

workload

Comments/ specify:

With biogas no labour for fuelwood collection. Time and effort previously used for firewood collection is freed

Socio-cultural impacts

SLM/ land degradation knowledge

conflict mitigation

Comments/ specify:

Future conflict over fuelwood resources would be averted. In case of no ownership of cattle.

situation of socially and economically disadvantaged groups

Comments/ specify:

Less demand on the time and labour of women and the girl child who are the main collecters of fuelwood

Gender related issues

Comments/ specify:

Where taboos exist for women harvesting dung from kraals (livestock enclosure); this could constrain adoption along gender lines

Improved livelihoods and human well-being

Comments/ specify:

Provides cheaper and alternative source of energy. Reduces workload for fuelwood collection for women and the girl child.

Ecological impacts

Water cycle/ runoff

water quantity

Comments/ specify:

Due to reduced plant cover

Soil

soil cover

Comments/ specify:

More trees certaily provides soil cover. But problems possible when plant cover is reduced as a result of less manure

nutrient cycling/ recharge

Comments/ specify:

Reduced soil fertility with distance from water points/kraals

salinity

soil organic matter/ below ground C

Comments/ specify:

Due to redused animal manure

Biodiversity: vegetation, animals

biomass/ above ground C

Comments/ specify:

Trees would have more density or cover

plant diversity

Comments/ specify:

Wood collectors target specific species

Climate and disaster risk reduction

emission of carbon and greenhouse gases

Comments/ specify:

Large scale adoption of biogas production may introduce air pollution. Also unpleasent smell around the village.

Other ecological impacts

Concentration of nutrients (dung)

Comments/ specify:

Cow dung will be reduce around water points and kraals

6.2 Off-site impacts the Technology has shown

water availability

reliable and stable stream flows in dry season

groundwater/ river pollution

buffering/ filtering capacity

wind transported sediments

damage on neighbours' fields

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

| temperature decrease | not well |

Comments:

Biogas technology may be limited under extreme cold conditions whereby fermentation may be limited by cold temperatures.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

Comments:

Very costly to set up, if no government aid. It is however very good for long term water provision.

6.5 Adoption of the Technology

If available, quantify (no. of households and/ or area covered):

10

Comments:

1% of land user families have adopted the Technology with external material support

10 land user families have adopted the Technology with external material support

Comments on acceptance with external material support: A very insignificant number of individual farmers have used this technology

Comments on spontaneous adoption: The technology has mostly been used where the Research institution has installed in farmers' properties. Only in very few instances around the country have individuals installed it for themselves.

There is a little trend towards spontaneous adoption of the Technology

Comments on adoption trend: There seems to be very little marketing of biogas in the country

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

Problems of diminishing firewood species are reduced. How can they be sustained / enhanced? Because it is not every or all species that is used for firewood, the targeted species are quickly diminished |

|

Cost of getting firewood is reduced How can they be sustained / enhanced? Distance to wood collection places are ever increasing hence users have to buy from truck or donkey cart owners |

|

More time is freed How can they be sustained / enhanced? This especially applies to children (of school going age) in that they would have more time for their home works. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Low maintenance and inputs are required for this technology How can they be sustained / enhanced? There is need for promotion of the technology |

|

The structures to be put in place are very basic How can they be sustained / enhanced? There is need for the government to subsidize farmers in installing biogas plants, especially in the rual areas. |

|

Good for rural households where firewood is used extensively. How can they be sustained / enhanced? Improve income of rural families so that they could afford the technology |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Too expensive for poor farmers to adopt without assistance | Donor/government subsidies |

7. References and links

7.2 References to available publications

Title, author, year, ISBN:

Brown, V. J., 2006. BIOGAS: A Bright Idea for Africa. Environ Health Perspectives. 114(5), pp. A300–A303.

Available from where? Costs?

internet

Title, author, year, ISBN:

Dayal, M., Vimal, O.P., Singh, K.K., 1989. Biomass gasification in India — DNES activities. Biomass, Volume 18, issues 3-4,pp. 197-204

Available from where? Costs?

http://www.ganesha.co.uk/Articles/Biogas%20Technology%20in%20India.htm

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules