Energy efficiency measures to increase the application of organic fertilisers. [Tajikistan]

- Creation:

- Update:

- Compiler: Daler Domullojonov

- Editor: –

- Reviewers: Laura Ebneter, Alexandra Gavilano, Fabian Ottiger

Бехтар намудани хосилнокии замин ба воситаи амалигардонии чорахои самаранокии истифодабарии неру

technologies_1050 - Tajikistan

- Full summary as PDF

- Full summary as PDF for print

- Full summary in the browser

- Full summary (unformatted)

- Energy efficiency measures to increase the application of organic fertilisers.: Nov. 2, 2021 (public)

- Energy efficiency measures to increase the application of organic fertilisers.: Aug. 14, 2019 (inactive)

- Energy efficiency measures to increase the application of organic fertilisers.: Julie 21, 2017 (inactive)

- Energy efficiency measures to increase the application of organic fertilisers.: Junie 2, 2017 (inactive)

- Energy efficiency measures to increase the application of organic fertilisers.: Mei 31, 2017 (inactive)

- Energy efficiency measures to increase the application of organic fertilisers.: Des. 27, 2016 (inactive)

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Hafizova Tahmina

Welthungerhilfe

Germany

SLM specialist:

Olimov Nazarmad

Welthungerhilfe

Germany

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Deutsche Welthungerhilfe e. V. (Welthungerhilfe) - Tajikistan1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

30/04/2011

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

The implementation of several low cost energy efficiency measures to reduce the amount of organic material used as fuel within rural households.

2.2 Detailed description of the Technology

Description:

In many cases local inhabitants of rural areas depend heavily on locally available natural resources, contributing to, and accelerating deforestation. As a low cost fuel source, local households often use cow-dung and wood. Taking these from the local area contributes to decreased soil fertility and erosion processes. Most of the dung collected from livestock is burnt in a very inefficient manner for cooking, baking and heating purposes. Based upon assessments by Welthungerhilfe in 600 households (HH) who were using cow dung as the only fuel material, on average one HH uses 4.6 tons of cow dung annually when using traditional cooking stoves, 6 tons for heating and 4.5 tons for bread baking. This means almost 15.1 tons of cow dung is burnt annually per HH.

Using a simple modification of the traditional cooking stove, approximately 50 - 60% or 2.3 tons of fuel material can be saved. This saving can be further increased by the utilisation of a pressure cooker that decreases the cooking time by 50%. Not all local hot meals can be cooked with a pressure cooker but it can contribute to an additional saving of 0.7 ton of organic matter.

The introduction of a metal heat exchanger on the exhaust pipe of a cast iron stove can help save a household 3 tons of fuel material per year, the effectiveness can be further increased by the incorporation of bread baking compartment.

Further savings can be made by using straw, mud and wood to improve the thermal insulation of the exterior walls, ceiling and floor in the house.

Through the integration of all above measures approx 60% of the current usage rates of organic material used for fuel can be saved. In addition it will keep the house warmer for longer, reduce the smoke in the air, and help retain organic material in the soil.

Purpose of the Technology: The main objective of the energy efficiency technology is to address one of the root causes of the deforestation process and to improve soil fertility i.e. to decrease the demand from the local population for organic fuel. This project used a range of technologies to address this issue which in combination provided substantial savings in organic fuel.

Establishment / maintenance activities and inputs: Cooking stoves: For centuries local populations have been using traditional cooking stoves for cooking, especially during the warm seasons of the year. These were made from a mixture of mud and straw. The modification of these involves improving the aeration process during the burning of the fuel. This is achieved by putting a metallic cover with one inflow cutting and six small smoke outflow holes surrounding the cooking pot. The only input needed which is not locally available is the metallic cover.

Pressure cookers: As maintenance is required 1-2 times per season to keep the cooking stove functioning efficiently, the utilisation of pressure cookers can be easily integrated with the modified cooking stoves.

Heat exchangers: The heat exchangers installed on top of the iron ovens, can be produced by local tradesmen and need to be cleaned every 1-2 months. They have to be installed before the start of the winter season when the heating is needed.

House installation: The house insulation, using locally available materials does not need maintenance once it is installed. However, the storage of dry fruits or bread in the attic should be avoided as it could attract mice which can destroy the insulation.

Welhungerhilfe provided subsidies for all the above work, except for the heat exchangers.

Natural / human environment: The geographical area served by the project is mainly hill slopes, covered in low grade pasture fodder with wheat crops planted in loess soil. Although the soils have the potential to be very fertile, they are overused and not well managed and thus have become degraded and denuded. One of the main contributing factors to this is the removal of organic material from the biomass cycle. Trees, bushes and organic material is cut and collected to be used as fuel.

The main source of income in the area is from semi-subsistence farming, and the removal of organic material has a significant impact on their crops and livestock.

The houses are made from concrete foundations and mud bricks, these and the current stoves are all energy inefficient and fail to retain heat.

2.3 Photos of the Technology

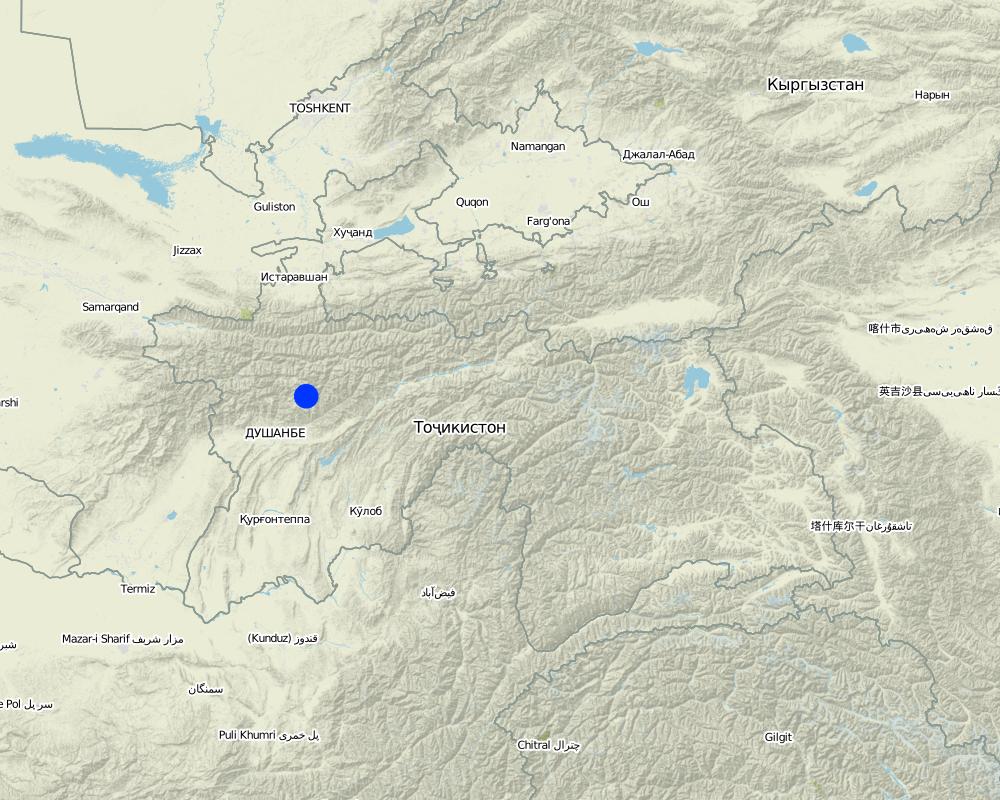

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Tajikistan

Region/ State/ Province:

Tajikistan / Khatlon

Further specification of location:

Temurmalik . Davad

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Promotion of energy efficiency measures began in 2007 by Welthungerhilfe projects

3. Classification of the SLM Technology

3.2 Current land use type(s) where the Technology is applied

Settlements, infrastructure

Comments:

Major land use problems (compiler’s opinion): The land in rural Tajikistan is becomming denuded due to the pressure for organic fertilisers used as a source of fuel for heating and cooking. This impacts on soil quailty, yields and soil stability. This issue is compounded by the relatively high price of mineral fertilisers.

Major land use problems (land users’ perception): Crop yields decrease.

3.3 Further information about land use

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 220Longest growing period from month to month: march - october

3.5 Spread of the Technology

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, indicate approximate area covered:

- > 10,000 km2

Comments:

Several energy efficiency measures were implemented by households in three neighbouring districts; Baljuvon, Temurmalik and Khovaling. These included the following: cooking stoves were modified in 1,924 HHs (households), pressure cookers were used in 132 HHS, heat exchangers were used in 569 HHs, improved house insulation in 850 HHs, and group bread baking - 10 groups (average of 10 families in each group).

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

structural measures

- S11: Others

Comments:

Main measures: structural measures

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

physical soil deterioration

- Pc: compaction

Comments:

Main type of degradation addressed: Cn: fertility decline and reduced organic matter content

Secondary types of degradation addressed: Pc: compaction

Main causes of degradation: soil management (poor ploughing practices), deforestation / removal of natural vegetation (incl. forest fires) (deforestation), over-exploitation of vegetation for domestic use (removal of trees and bushes for fuel pruposes.), overgrazing (imbalance of carrying capacity and size of livestock herds.), disturbance of water cycle (infiltration / runoff) (reduced infiltration capacity.), poverty / wealth (local population have restricted funds)

Secondary causes of degradation: crop management (annual, perennial, tree/shrub) (monoculture), change of seasonal rainfall (more intensive heavy rainfall events), droughts (events occuring more frequently), population pressure (population is increasing), labour availability (external labour migration)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

Comments:

Main goals: prevention of land degradation

Secondary goals: mitigation / reduction of land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Author:

Daler Domullojonov, 14, Giprozem street, app. 27, Dushanbe, Tajikistan

4.2 Technical specifications/ explanations of technical drawing

Heat exchanger adopted by Welthungerhilfe, promoted in communities of the Khatlon region of Tajikistan.

Location: Temurmalik, Baljuvon and Khovaling districts. Khatlon region / Tajikistan

Date: September, 2009

Technical knowledge required for field staff / advisors: high (promotion of EE measures)

Technical knowledge required for land users: moderate (cooking stove modification and use of pressure cookers, mainly by females)

Technical knowledge required for Local masters: high (for construction of heat exchangers and improving house thermal insulation)

Main technical functions: increase in organic matter

Secondary technical functions: improvement of topsoil structure (compaction), increase of infiltration, increase of biomass (quantity)

Structural measure: cook stove

Structural measure: House insulation

Structural measure: Presure cooker

Structural measure: Heat exchanger

4.3 General information regarding the calculation of inputs and costs

other/ national currency (specify):

TJS

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

4.5

Indicate average wage cost of hired labour per day:

11.00

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Cook stove modification | Structural | any |

| 2. | Pressure cooker | Structural | any |

| 3. | House insulation | Structural | once in the beginning |

| 4. | heat exchanger | Structural | once in the beginning |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | per stove | 1.0 | 5.5 | 5.5 | 100.0 |

| Labour | Labour | per room | 1.0 | 37.8 | 37.8 | 100.0 |

| Plant material | Wheat straw | bales | 12.0 | 4.9 | 58.8 | 100.0 |

| Construction material | Metallic cover | per stove | 1.0 | 5.1 | 5.1 | 34.0 |

| Construction material | Earth | per stove | 1.0 | 0.5 | 0.5 | 100.0 |

| Construction material | Wooden lath | per room | 1.0 | 72.0 | 72.0 | 15.0 |

| Construction material | Nail, lime, brush, emalen | per room | 1.0 | 30.75 | 30.75 | 100.0 |

| Construction material | Veneer and glueing silicone | per room | 1.0 | 43.8 | 43.8 | 100.0 |

| Other | Pressure cooker | piece | 1.0 | 22.2 | 22.2 | 80.0 |

| Other | heat exchanger | per stove | 1.0 | 30.0 | 30.0 | 100.0 |

| Other | Transportation cost | 1.0 | 44.0 | 44.0 | 100.0 | |

| Total costs for establishment of the Technology | 350.45 | |||||

Comments:

Duration of establishment phase: 12 month(s)

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | adjustment of modified cook stove | Structural | twice per year |

| 2. | cleaning of heat exchanger | Structural | twice per year |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | per stove | 1.0 | 3.3 | 3.3 | 100.0 |

| Total costs for maintenance of the Technology | 3.3 | |||||

Comments:

Machinery/ tools: brush

The costs are based upon 2010 prices.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The price of the construction materials are dependent on many different external factors, and prices are generally increasing seasonally and annually.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

Thermal climate class: temperate. 3 months below 5 degrees, 7 months above 10 degrees

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

medium

Water quality (untreated):

unusable

5.5 Biodiversity

Comments and further specifications on biodiversity:

Species diversity: medium, low

5.6 Characteristics of land users applying the Technology

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- very poor

- poor

Individuals or groups:

- individual/ household

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Population density: 10-50 persons/km2

Annual population growth: 1% - 2%

90% of the land users are poor.

10% of the land users are poor.

Off-farm income specification: local inhabitants are in many cases dependent on remittances from Russia and other income generating activities.

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

Comments:

There are a variety of land user and water rights within the three districts, but they do not directly affect the implementation of the technologies.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

12 t/ha

Quantity after SLM:

21 t/ ha

risk of production failure

Income and costs

expenses on agricultural inputs

farm income

Quantity before SLM:

TJS 100

Quantity after SLM:

TJS 1200

Socio-cultural impacts

food security/ self-sufficiency

health situation

conflict mitigation

Ecological impacts

Soil

soil loss

soil compaction

Biodiversity: vegetation, animals

biomass/ above ground C

Other ecological impacts

reduce fuel costs

warmer houses, health benefits

pressure cooker

Comments/ specify:

Not possible to cook all meals in this

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not known |

| local windstorm | not known |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not known |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

Comments:

The thermal could be modified to increase its thermal properties.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

Comments:

As it uses mainly locally available materials, it is a low cost approach which increases energy efficiency and improves resource use.

6.5 Adoption of the Technology

Comments:

70% of land user families have adopted the Technology with external material support

1355 land user families have adopted the Technology with external material support

Comments on acceptance with external material support: The amount of the local's contribution to the project themselves was between 52.7% to 100%.

30% of land user families have adopted the Technology without any external material support

569 land user families have adopted the Technology without any external material support

Comments on spontaneous adoption: Fitting heat exchangers, adapting cooking stoves, and improving house thermal insulation are the main forms of technology that have been replicated in the above households.

There is a little trend towards spontaneous adoption of the Technology

Comments on adoption trend: This is restricted due to limited access to funds.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

It is very affordable How can they be sustained / enhanced? By involving local relevant authorities and departments |

| It saves and minimises expenditures for electricity, gas, and firewood procurement |

| The rooms are warmer and I can cook bread inside and save more fuel. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

It is a low cost measure using locally available materials. The heat exchanger can improve the heating capacity of the room threefold, for example. How can they be sustained / enhanced? replication rates could be increased through promotion to larger audiences with support of local authorities or by law. |

|

It is environmental friendly and increases the amount of organic material that stays within the soil. How can they be sustained / enhanced? There could be further awareness raising of the benefits of keeping organic materials in the soil. |

| It saves time for collecting fire material wood and cow dung. |

| It presents an opportunity to increase land productivity through application of organic fertilisers |

|

The technologies do not have a large initial financial cost and can be implemented progressively as funds become available. How can they be sustained / enhanced? Training of more local teachers to provide demonstrations to the community. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| More labour needed to cut fuel into smaller pieces | Behavioural change |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Not all meals can be cooked in a pressure cooker | |

| Heat exchangers can get very hot for cooking purposes |

7. References and links

7.2 References to available publications

Title, author, year, ISBN:

Brochure "Soil improvement starts with efficient cook stoves! low cost options to increase energy efficiency in Southern Tajikistan"

Available from where? Costs?

Weltgungerhilfe projects in Khatlon region, Temurmalik district

Title, author, year, ISBN:

Welthungerhilfe project final narrative report (144-912)

Available from where? Costs?

Weltgungerhilfe projects in Khatlon region, Temurmalik district

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules