Dairy cattle fed with supplementary fodder [Uganda]

- Creation:

- Update:

- Compiler: Aine Amon

- Editors: Aine Amon, Drake Mubiru

- Reviewers: Rima Mekdaschi Studer, Hanspeter Liniger, Donia Mühlematter

Ebinyasi bye ente

technologies_3367 - Uganda

- Full summary as PDF

- Full summary as PDF for print

- Full summary in the browser

- Full summary (unformatted)

- Dairy cattle fed with supplementary fodder: Aug. 10, 2018 (inactive)

- Dairy cattle fed with supplementary fodder: Aug. 22, 2019 (public)

- Dairy cattle fed with supplementary fodder : Junie 20, 2018 (inactive)

- Dairy cattle fed with supplementary fodder : Junie 20, 2018 (inactive)

- Cattle Fodder processing: Junie 15, 2018 (inactive)

- Cattle Fodder processing: Mei 21, 2018 (inactive)

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

National Agricultural Research Organisation (NARO) - Uganda1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

19/01/2018

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

Nee

1.5 Reference to Questionnaire(s) on SLM Approaches

Fodder Crops Production [Türkiye]

To grow different fodder crop species (leguminous and graminous) for feeding livestock

- Compiler: Unknown User

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

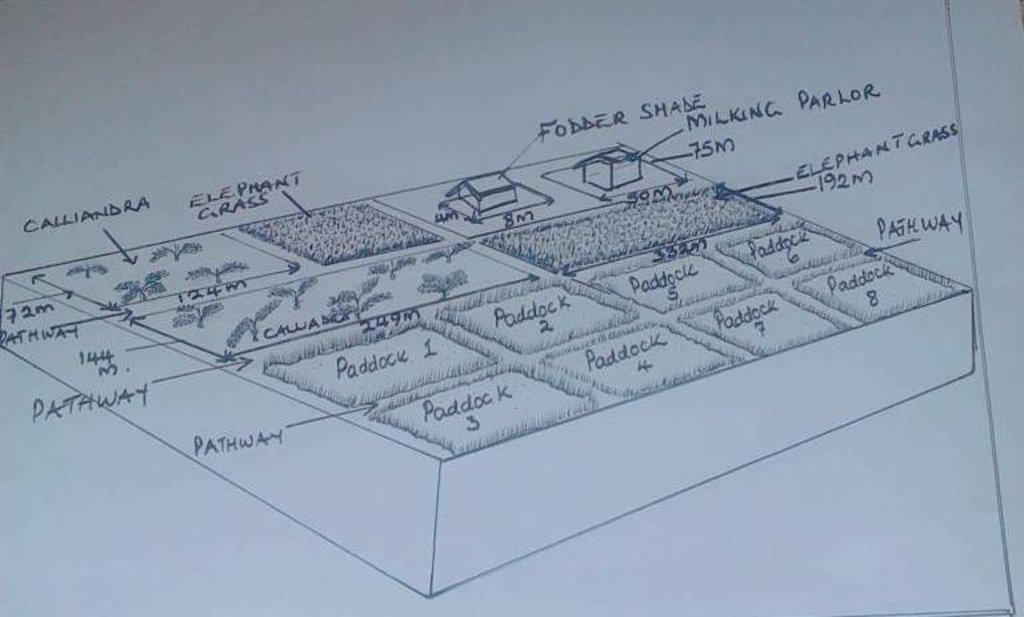

Elephant grass (Pennisteum purpureum) and calliandra (Calliandra calothyrsus), are harvested and chopped using a chaff cutter to produce fodder for dairy cows. The chaff is then mixed with cotton seed cake, molasses and maize bran to improve palatability and nutrient quality for dairy cows. The cattle graze in paddocks during the day and receive the fodder at evening milking.

2.2 Detailed description of the Technology

Description:

High quality fodder for livestock is made by mixing chaff of elephant grass (Pennisteum purpureum) and calliandra (Calliandra calothyrsus) with maize bran, cotton seed cake and molasses. These fodder pastures are grown on a 10 acre piece of land and harvested twice a week for chopping into chaff. For calliandra (a leguminous tree), leaves are harvested while elephant grass is cut at ground level. This vegetation is transported to the electric chaff cutter by tractor. At its best, the chaff is evenly cut, free of dust, of good colour and has a fresh aroma. The chaff is chopped into small pieces which allows for easy mixing with supplements. Chaff in Uganda can be produced on farm or purchased from commercial chaff cutting mills, which grow pastures and process them for sell to farmers during pasture scarcity in the long dry spells.

The farmer in Bushenyi District learnt the technology at a trade show. Today, he processes fodder for his 50 dairy cattle under an intensive system. His grazing/paddock land is about 20 hectares in total and is divided into 8 paddocks which are used in rotation. The cows graze for 8 hours daily. Every evening their diet is supplemented with the processed fodder in the milking parlour. The fields are allowed to mature at intervals to produce a continuous supply of grass for fodder throughout the growing season. The fodder processing procedure includes:

i) Cutting mature pasture grass at ground level and collecting the grass from the fields;

ii) Transportation of elephant grass and calliandrafrom the fields to the fodder shed;

iii) Offloading and sorting of pasture grass/ fodder into different classes of similar diameter and lengths for easy handling during chaff cutting;

iv) Chopping of pastures/ fodder into small pieces using the electric chaff cutter;

v) Mixing the chaffed fodder, cotton seed cake, molasses and maize bran to improve the palatability and nutrient quality of the chaffed fodder.

vi). Putting the processed fodder into troughs for cattle to feed on during milking.

Processing enough pasture grass into chaff for cattle feeding is described by the farmer to be a relatively expensive and a labour intensive process. The key expenses in establishing the system include costs of buying fodder (if not readily available on the farm), purchasing a chaff cutter and buying supplements. The farmer requires 0.5 tonnes of chaffed fodder mixed with supplements to feed 50 dairy cows on a daily basis. The main costs are labour, fodder supplements, the electric chaff cutter, tractor hire and daily operation costs.

The fodder cut into small pieces mixes easily with supplements to make a well nutrient balanced ration. This is palatable and encourages cattle to eat non-selectively and without spilling,hence minimizing wastage. The processed fodder is easy to store in bags and can be kept on wooden pallets raised off ground in a cool store. The farmer notes that the chaffed fodder can further be processed into hay or silage for storage to be fed to cattle during the seasons of pasture scarcity, especially the long dry spells of early June to late August and early December to late February. The system enables the farmer to keep more productive animals on his land than he could using other feeding regimes: in other words this is an intensive system that maximizes production per unit area.

2.3 Photos of the Technology

2.4 Videos of the Technology

Comments, short description:

The video features Elephant grass fodder being sorted at the fodder shade, the chaff cutter, chaffed fodder and a view of the feeding troughs at the milking parlor.

Date:

19/01/2018

Location:

Uganda, Bushenyi District, Kyamuhunga sub county

Name of videographer:

Aine Amon

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Uganda, Western Region

Further specification of location:

Bushenyi District, Kyamuhunga sub county

Map

×2.6 Date of implementation

Indicate year of implementation:

2016

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

Comments (type of project, etc.):

Chopping pastures for silage making.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce risk of disasters

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Grazing land

Intensive grazing/ fodder production:

- Cut-and-carry/ zero grazing

- Improved pastures

Comments:

The farmer has a 400 acres of land under cattle grazing, tea growing, pasture growing and fish farming.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

In the dry season the farmer irrigates with water from the valley.

Number of growing seasons per year:

- 2

Livestock density (if relevant):

50 cows on 22 hectares including the milking parlour, fodder shed and stores are established.

3.4 SLM group to which the Technology belongs

- pastoralism and grazing land management

- integrated crop-livestock management

- improved plant varieties/ animal breeds

3.5 Spread of the Technology

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, indicate approximate area covered:

- 0.1-1 km2

3.6 SLM measures comprising the Technology

other measures

Comments:

The process is for making high quality pasture suplements for cattle.

3.7 Main types of land degradation addressed by the Technology

physical soil deterioration

- Pc: compaction

- Pu: loss of bio-productive function due to other activities

biological degradation

- Bc: reduction of vegetation cover

- Bh: loss of habitats

other

Comments:

Increased productivity per soil unit.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

- adapt to land degradation

4. Technical specifications, implementation activities, inputs, and costs

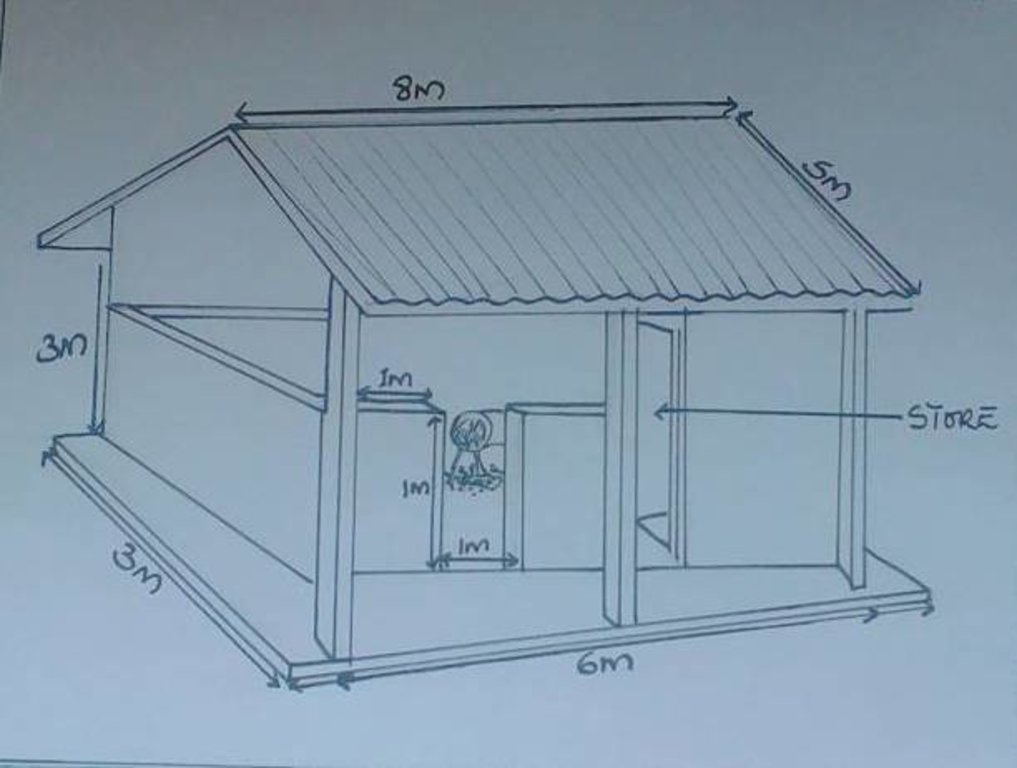

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

The key requirements for the system are the fodder shed, chaff cutter and sources of pastures. The fodder shed of 3×6×6m was constructed close to the milking parlour for efficiency. A store of 2×2×2m for the chaff cutter and other equipment was constructed in one of the corners of the shed. Apart from the store, all other walls are constructed up to one meter height leaving two metres open to the roof for ventilation.

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

other/ national currency (specify):

Uganda shillings

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

3638.0

Indicate average wage cost of hired labour per day:

10000

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Clearing and Preparation of the garden. | Management | Best done at the end of the dry season. |

| 2. | Planting of the desired improved pastures for fodder. | Management | At the start of the rain season. |

| 3. | Construction of the fodder shed and store. | Management | Before the pastures are mature enough to start harvesting. |

| 4. | Purchase and establishment of the chaff cutter. | Management | After establishment of the fodder shelter and store. |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labor | man/day | 12.0 | 10000.0 | 120000.0 | |

| Equipment | Hoe | Pieces | 2.0 | 15000.0 | 30000.0 | |

| Equipment | Panga | Pieces | 1.0 | 5000.0 | 5000.0 | |

| Equipment | Hammer | pieces | 1.0 | 5000.0 | 5000.0 | |

| Equipment | wheel burrow | Pieces | 1.0 | 5000.0 | 5000.0 | |

| Equipment | Tractor hire | Hours | 10.0 | 50000.0 | 500000.0 | |

| Equipment | chaff cutter | unit | 1.0 | 1500000.0 | 1500000.0 | |

| Construction material | Metal rods | Pieces | 4.0 | 20000.0 | 80000.0 | |

| Construction material | Cement | 50kg bags | 20.0 | 29000.0 | 580000.0 | |

| Construction material | Sand | Tonnes | 2.5 | 70000.0 | 175000.0 | |

| Construction material | Bricks | Pieces | 10000.0 | 150.0 | 1500000.0 | |

| Construction material | Timber | Pieces | 20.0 | 5000.0 | 100000.0 | |

| Construction material | Iron sheets | Sheets | 24.0 | 42000.0 | 1008000.0 | |

| Construction material | Gravel | Trips | 1.0 | 75000.0 | 75000.0 | |

| Total costs for establishment of the Technology | 5683000.0 | |||||

Comments:

Bio gas solutions Uganda funded 10% ie establishment of mixing chamber for biogas which works as the mixing chamber for the irrigation fertilizer technology.

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Cutting and collecting of mature elephant grass (Pennisteum purpureum),and calliandra (Calliandra calothyrsus) to one point in the fields. | Management | each morning. |

| 2. | Transportation of pasture grass to the fodder shed. | Management | After cutting. |

| 3. | Offloading and sorting of pasture at the fodder shed. | Management | |

| 4. | Chopping of grass into small units using the electric chaff cutter. | Management | |

| 5. | Mixing the chaff with supplements. | Management | When the pastures are well chopped. |

| 6. | Feeding the processed fodder in troughs. | Management | 30 minutes to milking time at dusk. |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labor | Men/month | 4.0 | 10000.0 | 40000.0 | 100.0 |

| Equipment | Panga | |||||

| Other | Elephant grass (Pennisteum purpureum) and calliandra (Calliandracalothyrsus) | tonnes | 0.5 | 100000.0 | 50000.0 | 100.0 |

| Other | Maize bran | tonnes | 0.0625 | 88000.0 | 5500.0 | 100.0 |

| Other | Molasses | tonnes | 0.13 | 173000.0 | 22490.0 | 100.0 |

| Other | Cotton seed cake | tonnes | 0.0625 | 88000.0 | 5500.0 | 100.0 |

| Total costs for maintenance of the Technology | 123490.0 | |||||

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Establishing the fodder shade, purchasing the chaff cutter and daily operation costs.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

March to May and Sept to Nov

Agro-climatic zone

- humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

poor drinking water (treatment required)

Is water salinity a problem?

Nee

Is flooding of the area occurring?

Nee

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- commercial/ market

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- very rich

Individuals or groups:

- individual/ household

Level of mechanization:

- mechanized/ motorized

Gender:

- men

Age of land users:

- elderly

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- large-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

fodder production

fodder quality

Comments/ specify:

Supplements are added to chaffed fodder

animal production

Comments/ specify:

The grazing cows are supplemented with fodder at milking in the evining

risk of production failure

Comments/ specify:

Better quality and quantity pastures available for feeding livestock

Income and costs

expenses on agricultural inputs

farm income

Comments/ specify:

Increased milk production per cow

workload

Comments/ specify:

Need to grow pasture grass and process them into chaffed supplemented fodder

Ecological impacts

Biodiversity: vegetation, animals

Vegetation cover

biomass/ above ground C

Comments/ specify:

Cut and carry systems can drain the fields of nutrients if not replenished with fertilizer

beneficial species

Comments/ specify:

Calliandra and elephant grass

Climate and disaster risk reduction

drought impacts

Comments/ specify:

It is possible to store and supplement livestock feed in the dry season if processed into hay

emission of carbon and greenhouse gases

Comments/ specify:

Pastures grown are carbon sinks

6.2 Off-site impacts the Technology has shown

downstream siltation

Comments/ specify:

The pastures act as cover crops to regulate run off

damage on neighbours' fields

Comments/ specify:

Cattle have enough feed and therefore don’t need to trespass onto neighbors’ fields

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | decrease | not well | |

| seasonal temperature | dry season | increase | moderately |

| annual rainfall | decrease | well | |

| seasonal rainfall | wet/ rainy season | decrease | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| landslide | well |

Biological disasters

| How does the Technology cope with it? | |

|---|---|

| epidemic diseases | not well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

negative

Long-term returns:

positive

6.5 Adoption of the Technology

- 1-10%

If available, quantify (no. of households and/ or area covered):

1

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 90-100%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Nee

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| The animals feed in the paddocks during the day and are supplemented with more palatable fodder at the milking parlor, to improve their diet. |

| The nutrient quality of the fodder is supplemented to make a more balanced ration for the animals. |

| Under this semi intensive farming system, more animals can be reared per unit area in contrast to a paddock-only system. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The farmer can further process the pastures into hay or silage for storage. |

| The animals are not so much affected by pasture scarcities. |

| There is chance to irrigate the pastures to cope with the long dry seasons. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Expensive to maintain. Production of enough grass at one go and storage for use in the next few days | Production of enough pastures at ago and storing them for use in the next few days. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Need for labour for processing. Further mechanization of the process. | Further Mechanization of the process. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

1

- interviews with land users

1

Links and modules

Expand all Collapse allLinks

Fodder Crops Production [Türkiye]

To grow different fodder crop species (leguminous and graminous) for feeding livestock

- Compiler: Unknown User

Modules

No modules