Low-cost solar drier for preserving crop produce [Uganda]

- Creation:

- Update:

- Compiler: Sunday Balla Amale

- Editors: JOY TUKAHIRWA, Kamugisha Rick Nelson, Bernard Fungo, betty adoch

- Reviewers: John Stephen Tenywa, Nicole Harari, Alexandra Gavilano

twoyo cam ki cheny

technologies_3330 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Odong Kilama

Local Farmer

Uganda

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Uganda Landcare Network (ULN) - Uganda1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

Nee

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

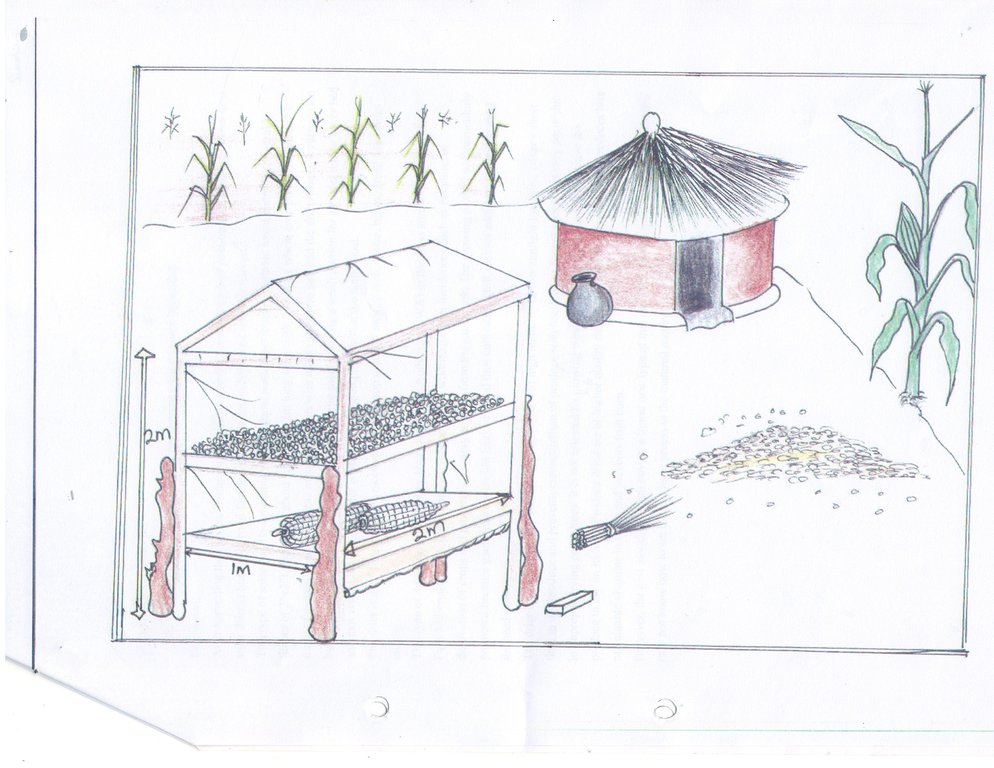

A portable wooden frame solar drier with polythene cover used for drying low moisture content crop produce such as chili and maize. The crop is placed inside the drier and takes 2-3 days to dry depending on the humidity and moisture content at harvest.

2.2 Detailed description of the Technology

Description:

Postharvest crop losses constitute a major concern among farming communities in northern Uganda. This is primarily due to suboptimal drying facilities used by farmers, despite the availability of all year round natural solar radiation. It was in light of this challenge that the Uganda Wildlife Authority (UWA) introduced and promoted a low-cost handy solar drier among the rural farming communities in and around the Murchison Falls National Park. The purpose was to reduce human wildlife conflict incidences such as poaching or destruction of crops and properties by stray animals from the game park. The technology bears potential for out scaling to other non-targeted communities as well.

The drier consists of a wooden frame made from locally available wood material (preferably timber of 2" x 3"), measuring about 1 m wide by 2 m long and 2 m high. The floor where crop produce is placed is made of mesh of materials such as wire mesh or papyrus mat. The entire frame is surrounded by a 0.2 mm thick transparent UV stabilized plastic sheet, leaving a small portion for air inlet on the lower bed and exit vent at the top. The drier is placed in an open air place within the homestead.

The drier is most suited for drying low moisture content crop produce such as chili, maize, beans and green vegetables.

The drier is able to dry crop produce during periods of high humidity or low sunlight intensity, cover a short time to dry produce and prevents contamination of produce with bacterial or fungal spores that may occur due to improper drying procedures. It is not affected by blowing wind or rainfall; thus a farmer can leave the produce to dry on its own. Produce dried are of higher quality than when dried in open sun. The drier also reduces loss of valuable vitamins in fruits and prevents fruit burning. However, the cost associated with buying a brand new type of this drier made from modern materials is high.

2.3 Photos of the Technology

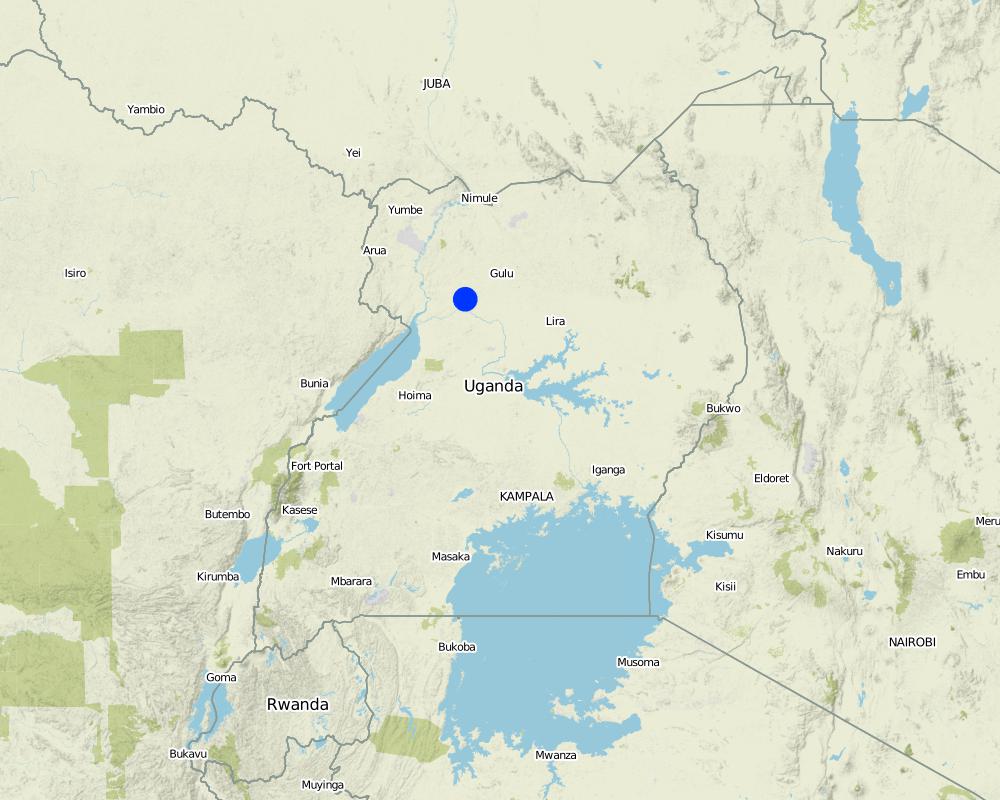

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Nwoya district

Further specification of location:

Anaka sub-county, Agung village

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

Farmer located in Agung Village, Laliya sub village

applied at specific points/ concentrated on a small area

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Project by Uganda Wildlife Authority for the neighboring communities surrounding the national park as a measure to result human wildlife conflicts through encouraging production of crops not destroyed by wildlife.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Annual cropping - Specify crops:

- cereals - maize

- legumes and pulses - beans

- chili, green vegetables, fruits

Number of growing seasons per year:

- 2

Specify:

1st rain mid march to june; 2nd rain mid july to november

Settlements, infrastructure

- Settlements, buildings

Remarks:

The technology is applied within the home stead

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- post-harvest measures

3.6 SLM measures comprising the Technology

other measures

Comments:

post harvest handling of farm produce

3.7 Main types of land degradation addressed by the Technology

other

Comments:

helps to preserve produce in sustainable way, thus indirectly addressing land degradation

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- not applicable

4. Technical specifications, implementation activities, inputs, and costs

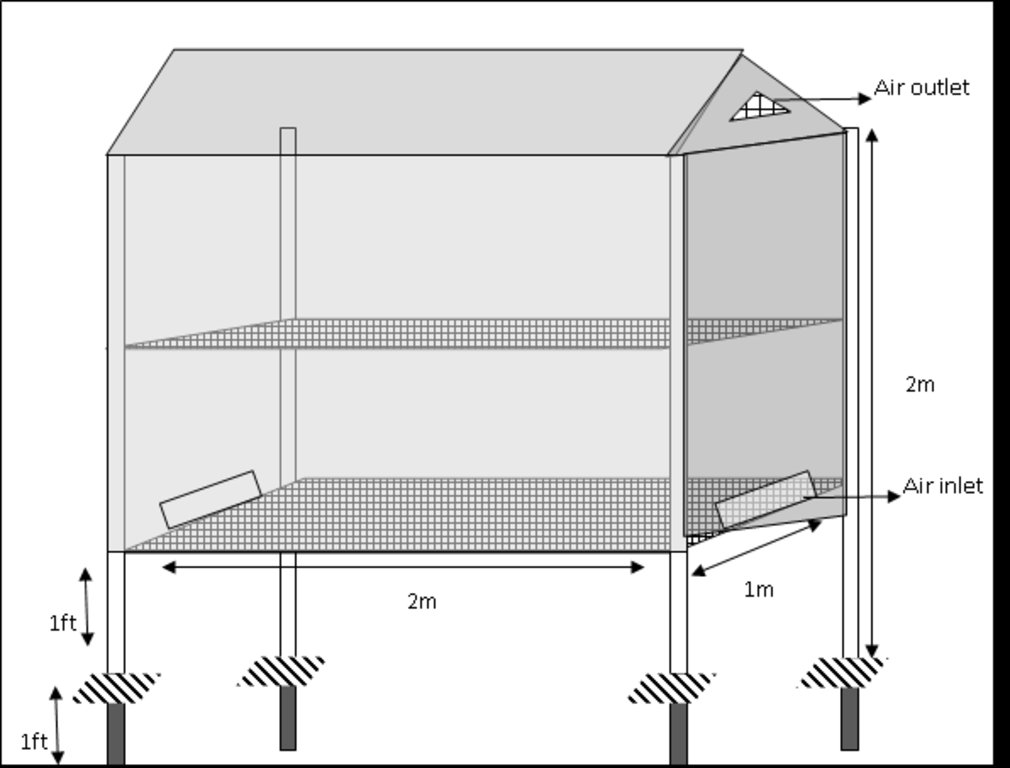

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Rectangular solar dryer of the following dimensions: about 1m wide, 2m long, 2m high. The stand enters 1 foot into the ground to ensure firmness. The tray for putting the produce is about 1 foot above the ground surface and ensures free circulation of air underneath, and also prevents domestic animals from feeding on the produce.

Author:

amale balla sunday

Date:

05/04/2018

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Solar dryer

other/ national currency (specify):

Uganda Shillings

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

3650.0

Indicate average wage cost of hired labour per day:

5000

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Acquiring materials for constructing the drier | any period of the year |

| 2. | Constructing the drier | anytime of the year |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | carpenter | personnel | 2.0 | 15000.0 | 30000.0 | |

| Construction material | Timber 3"X2" | pieces | 10.0 | 9000.0 | 90000.0 | |

| Construction material | Stabilised UV sheet | square meter | 12.0 | 15000.0 | 180000.0 | |

| Construction material | Iron nails assorted | kg | 2.0 | 6000.0 | 12000.0 | |

| Total costs for establishment of the Technology | 312000.0 | |||||

| Total costs for establishment of the Technology in USD | 85.48 | |||||

If you are unable to break down the costs in the table above, give an estimation of the total costs of establishing the Technology:

200000.0

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Uganda Wildlife Authority

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Repairs | anytime of the year |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | personnel | persons | 2.0 | 10000.0 | 20000.0 | 100.0 |

| Construction material | UV stabilized polythene sheet | square meters | 5.0 | 15000.0 | 75000.0 | 100.0 |

| Construction material | Iron nails (assorted) | kg | 1.0 | 6000.0 | 6000.0 | 100.0 |

| Total costs for maintenance of the Technology | 101000.0 | |||||

| Total costs for maintenance of the Technology in USD | 27.67 | |||||

Comments:

The solar drier is maintained whenever the polythene sheet tears off; usually after three years as recommended by Uganda Wildlife Authority

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Material costs for constructing the drier. These include cost of timber, stabilized UV polythene sheet and iron nails.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

convectional rainfall, two rainy seasons

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- coarse/ light (sandy)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

poor drinking water (treatment required)

Is water salinity a problem?

Nee

Is flooding of the area occurring?

Nee

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- poor

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

- men

Age of land users:

- youth

- middle-aged

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- communal (organized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

risk of production failure

Comments/ specify:

improved post harvest handling

Income and costs

farm income

Comments/ specify:

good quality product fetches better prices

workload

Comments/ specify:

the product stays in the drier during the drying period

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

good post harvest handling

6.2 Off-site impacts the Technology has shown

marketability of product

Comments/ specify:

better quality products

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well | |

| annual rainfall | increase | very well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| tropical storm | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

Project promoted by UWA

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Nee

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Crop produce take short time to dry |

| Dried products are of high quality |

| produce being dried is not disturbed by domestic animals, birds, wind or rain |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Efficient drying method utilizing greenhouse effect |

| Reduced contamination with bacterial or fungal spores during drying process |

| Produce does not need to be removed from drier everyday, it stays in the drier until properly dried |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| high cost of materials | Uganda Wildlife Authority did not empower the local people to make their own driers |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| can not be used for drying fruits and high moisture content produce | improvise additional sources of heating |

| did not empower local people to make their own driers | local people need to be empowered |

7. References and links

7.1 Methods/ sources of information

- interviews with land users

1

When were the data compiled (in the field)?

17/07/2017

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules