Small-Scale Nutrient-Dense Pellet Production [Tunisia]

- Creation:

- Update:

- Compiler: Joren Verbist

- Editor: –

- Reviewers: William Critchley, Rima Mekdaschi Studer

technologies_6486 - Tunisia

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

Agricultural Innovation Specialist:

Rudiger Udo

International Center of Agriculture Research in the Dry Areas (ICARDA)

Tunisia

Agricultural and Resource Economist:

Dhehibi Boubaker

International Center of Agriculture Research in the Dry Areas (ICARDA)

Tunisia

Forage Specialist:

El Ayed Monia

Tunisia

Forage Specialist:

Zaiem Anis

Tunisia

Economics and Participatory Methods:

Idoudi Zied

International Center of Agriculture Research in the Dry Areas (ICARDA)

Tunisia

Agricultural Economist:

Frija Aymen

International Center of Agriculture Research in the Dry Areas (ICARDA)

Tunisia

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

ICARDA Institutional Knowledge Management InitiativeName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

International Center for Agricultural Research in the Dry Areas (ICARDA) - Lebanon1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

Nee

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Lessons learned from the "Mind the Gap" project: … [Tunisia]

The “Mind the Gap” project researched the adoption gap between agricultural research and women and men farmers. Its objective was to determine most effective and cost-efficient technology transfer strategies and give recommendations to national extension institutes and development partners to adapt their scaling strategy

- Compiler: Joren Verbist

The 4-Wheels Approach for sustainable scaling [Tunisia]

The 4-Wheels Approach addresses the challenge of slow adoption of agricultural innovations among smallholder farmers by establishing Knowledge Hubs and partnerships with diverse stakeholders. The focus is on income-generating technologies and essential factors behind successful scaling up of innovations, ultimately driving agricultural modernization and sustainability.

- Compiler: Joren Verbist

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Compressing agro-industrial by-products produces nutrient-dense livestock feed pellets that can compete with expensive and imported alternatives. This innovation consists of a small-scale compressor or "pelletizer" and formulae to create feed pellets of sufficient quality with locally available inputs.

2.2 Detailed description of the Technology

Description:

In Tunisia, there are many agropastoralists who are dependent on expensive and imported feed pellets to improve livestock quality and to supplement feed shortages. Risks of relative shortages are likely to increase due to climate change. Simultaneously there are many discarded by-products from (local) agrofood supply chains such as olive cakes, date kernels, and downgraded dates, which contain good levels of nutrients. ICARDA saw an opportunity and, together with local partners, a machine was imported that is able to compress nutritious by-products into pellets. In addition to the machine, ICARDA and OEP experimented with feasible inputs and different ratios, considering local availability as well. It achieved highly dense and nutritious feed pellets from local available inputs, with similar quality to the imported pellets. There are currently two pelletizers on the market, a large model with a maximum capacity of 500 kilograms of pellets per hour, and a more affordable small pelletizer producing 125 kilogram per hour. Four formulae are recommended (see section 4.1). Two have olive cake as the main ingredient and the other two have date palm by-products as the key input. All formulae have an average protein content of 17% which is higher than imported pellets. The benefits include:

-Possibility of overcoming periods of fodder shortages

-Less dependence on expensive imports and price volatility

-Source of nutritious feed and improving livestock quality while reduced feeding costs

-Less pressure on grazing land and thereby reducing land degradation

-Joint purchase and use of a pelletizer by a farmer organization, improves social cohesion

-The pellets generate income and employment for the farmer organization

However the land users have experience challenges when acquiring permits for pellet production and electricity. In addition, there may be by-products supply constraints.

Information and data presented is partly made available through the projects “CRP livestock “Feed and Forages”” funded by CGIAR, and “SWC@scale” funded by GIZ. Projects were managed by the International Center for Agricultural Research in the Dry Areas (ICARDA) and implemented in Tunisia in collaboration with the Livestock and Pasture Office (OEP). Thus far, pelletizers have been made available by the CIGAR Research Program on Livestock (3 large and 2 small) and the German Organization for International Cooperation (GIZ) (a large and 2 small).

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Tunisia

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Is/are the technology site(s) located in a permanently protected area?

Nee

Map

×2.6 Date of implementation

Indicate year of implementation:

2019

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

Ja

Specify mixed land use (crops/ grazing/ trees):

- Agro-pastoralism (incl. integrated crop-livestock)

Cropland

- Annual cropping

Annual cropping - Specify crops:

- cereals - barley

Is intercropping practiced?

Nee

Is crop rotation practiced?

Nee

Grazing land

Extensive grazing:

- Semi-nomadic pastoralism

Intensive grazing/ fodder production:

- Cut-and-carry/ zero grazing

Animal type:

- cattle - dairy and beef (e.g. zebu)

- goats

- sheep

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- No (Continue with question 3.4)

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

3.5 SLM group to which the Technology belongs

- pastoralism and grazing land management

- integrated crop-livestock management

- post-harvest measures

3.6 SLM measures comprising the Technology

other measures

Specify:

The use of small scale machinery to convert by-products into feed pellets for livestock

3.7 Main types of land degradation addressed by the Technology

physical soil deterioration

- Pu: loss of bio-productive function due to other activities

other

Specify:

By using by-products it reduces the pressure of waste on the environment

Comments:

Degradation by overgrazing

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

- adapt to land degradation

Comments:

When land degradation reduces yields, feel pellets are able to compensate for this. In addition, the alternative of feed by pellets might reduce the pressure on the land for grazing, potentially preventing overgrazing.

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

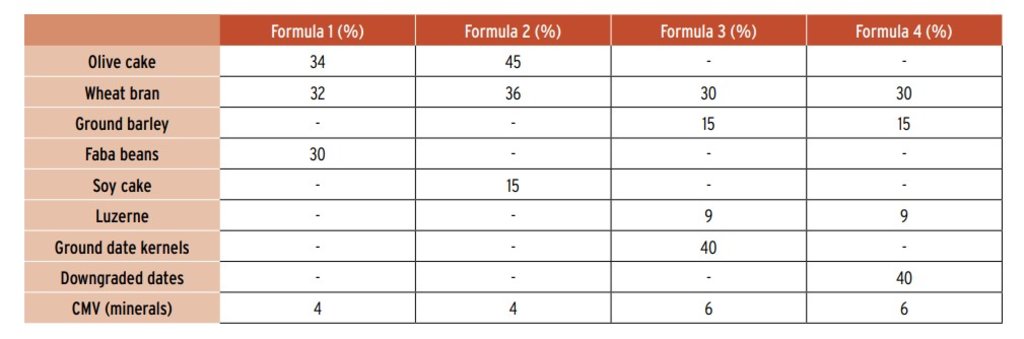

Input composition for different formulas

Author:

Rudiger, U., El Ayed, M., Idoudi, Z., Frija, A., Nefzaoui, A. and Gharsi, M. 2021. Nutrient-dense livestock feed pellets manufactured in Tunisia can compete with imported feed concentrates. Business Model Brief. Nairobi, Kenya: ILRI

Date:

2021

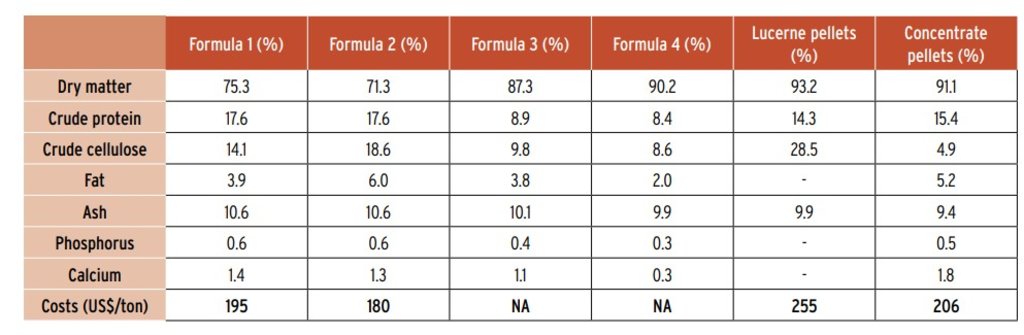

Technical specifications (related to technical drawing):

Nutritional value and costs of four pellet formulae compared to imported concentrates and lucerne pellets.

Author:

Rudiger, U., El Ayed, M., Idoudi, Z., Frija, A., Nefzaoui, A. and Gharsi, M. 2021. Nutrient-dense livestock feed pellets manufactured in Tunisia can compete with imported feed concentrates. Business Model Brief. Nairobi, Kenya: ILRI

Technical specifications (related to technical drawing):

Large Pelletizer:

-Production capacity < 500 kilogram per hour

-Power usage = 5 kilowatt per hours

-Voltage level = 380 volts

-Size = 930 by 550 by 1440 in millimeters

-Weight = 320 kilogram

Author:

Juhaina cooperation

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

1 ton of Pellets

other/ national currency (specify):

Tunisian Dinar

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

3.0

Indicate average wage cost of hired labour per day:

25

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Purchase Machine |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | Large Pelletizer | 1.0 | 9000.0 | 9000.0 | ||

| Total costs for establishment of the Technology | 9000.0 | |||||

| Total costs for establishment of the Technology in USD | 3000.0 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Gather raw feed materials for inputs | |

| 2. | Compress inputs into pellets using the pelletizer | |

| 3. | Feed the pellets to livestock |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Using the pelletizer | Person-hour | 2.0 | 3.0 | 6.0 | |

| Plant material | Olive cake | Kilogram | 340.0 | 0.07 | 23.8 | |

| Plant material | wheat bran | Kilogram | 320.0 | 0.25 | 80.0 | |

| Plant material | Faba Beans | Kilogram | 300.0 | 1.5 | 450.0 | |

| Plant material | Minerals | Kilogram | 40.0 | 0.44 | 17.6 | |

| Other | Electricity | Kilo watt | 30.0 | 0.3 | 9.0 | |

| Total costs for maintenance of the Technology | 586.4 | |||||

| Total costs for maintenance of the Technology in USD | 195.47 | |||||

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

This innovation can be implemented in many different environments.

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

Comments and further specifications on topography:

This innovation can be implemented in many different environments.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- coarse/ light (sandy)

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

This innovation can be implemented in many different environments.

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

poor/ none

Water quality (untreated):

poor drinking water (treatment required)

Water quality refers to:

ground water

Is water salinity a problem?

Ja

Is flooding of the area occurring?

Nee

Comments and further specifications on water quality and quantity:

This innovation can be implemented in many different environments.

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- low

Comments and further specifications on biodiversity:

This innovation can be implemented in many different environments.

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

- Semi-nomadic

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

- average

Individuals or groups:

- individual/ household

- groups/ community

Level of mechanization:

- mechanized/ motorized

Gender:

- women

- men

Age of land users:

- middle-aged

- elderly

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

- individual, titled

Land use rights:

- individual

Water use rights:

- communal (organized)

- individual

Are land use rights based on a traditional legal system?

Ja

Specify:

Land use rights in Tunisia have a long history with religious (e.g. melk) influences and French influences. This resulted in that currently most lands are private owned or state owned

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

fodder production

Comments/ specify:

Pellets allow for better storage of fodder and thus less loss of fodder, translating into improved production. Additionally, inputs that cannot be used as fodder directly, can now be processed by the pelletizer into fodder, also improving the production.

risk of production failure

Comments/ specify:

Since fodder can be better stored, farmers are better able to overcome failures. Additionally, by using the alternative inputs, feed production is diversified.

product diversity

Comments/ specify:

Other inputs are used hence production is diversified.

Income and costs

expenses on agricultural inputs

Comments/ specify:

Less cost on commercially produced pellets, and using the comparative advantage of this technology.

farm income

Comments/ specify:

The reduced cost translate improved in the increased farm income.

diversity of income sources

Comments/ specify:

Farmers may sell their own produced pellets, diversifying their income. In addition, farmers are now not solely dependent on their land as they can also use other inputs.

economic disparities

Comments/ specify:

Marginalized farmers have now comparative advantage.

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

They can produce their own pellets, thus less dependent on imports.

6.2 Off-site impacts the Technology has shown

pressure from by-products on the environment

Comments/ specify:

By making use of the by-products there is less pressure of them on the environment.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Nee

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Pellets can be easily stored, and then be used in periods of feed shortages |

| Pellets are made from local and cheap inputs |

| The pellets have good nutritional value, similar to the more expensive and imported pellets |

| The pelletizer is easy to use |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Inputs can come from by-products that would otherwise be wasted |

| Farmers are less dependent on expensive feed imports and their volatile prices |

| Pellets being an alternative feed source, reduces the pressure on grazing land |

| The pelletizer and produced pellets improve the value chain on a local level |

| When the pelleizer are used in a farmer organization context, it improves the cohesion within this organization. And it provides opportunity for further investment because pellets generate additional income. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Requires an initial investment |

Improve funding schemes with banks or government to support these investments. Farmers can purchase the machine as cooperative. |

| Difficult to arrange permits from the government | Developing an approach by extension workers, who can then help the farmers |

| Difficult to get a 380 volt power supply from electricity companies | Developing an approach by extension workers, who can then help the farmers |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| By-products as inputs, might be difficult to come by if the farmers lacks the right network | Set-up a network to connect farmers with producers of suitable by-products |

| By-products are often only periodically available | Experiment with different inputs that are available in other period, to ensure whole-year availability |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with SLM specialists/ experts

- compilation from reports and other existing documentation

When were the data compiled (in the field)?

2022

7.2 References to available publications

Title, author, year, ISBN:

Boubaker Dhehibi, Jebali Oussama, Aymen Frija, Udo Rudiger, Hassen Ouerghemmi, Zied Idoudi, Mourad Rekik, Monia Elayed, Anis Zaiem, Nizar Moujahed. (26/10/2022). Profitability of Manufactured Feed Pellets for Small-Scale Crop-Livestock Farmers in Tunisia. Beirut, Lebanon: International Center for Agricultural Research in the Dry Areas (ICARDA).

7.3 Links to relevant online information

Title/ description:

Udo Rudiger, Monia Aouinti. (2/6/2021). Locally manufactured feed pellets: Reducing chronic feed deficits and production costs/Les bouchons alimentaires: Réduire les déficits alimentaires chroniques et les coûts de

URL:

https://hdl.handle.net/20.500.11766/10159

Links and modules

Expand all Collapse allLinks

Lessons learned from the "Mind the Gap" project: … [Tunisia]

The “Mind the Gap” project researched the adoption gap between agricultural research and women and men farmers. Its objective was to determine most effective and cost-efficient technology transfer strategies and give recommendations to national extension institutes and development partners to adapt their scaling strategy

- Compiler: Joren Verbist

The 4-Wheels Approach for sustainable scaling [Tunisia]

The 4-Wheels Approach addresses the challenge of slow adoption of agricultural innovations among smallholder farmers by establishing Knowledge Hubs and partnerships with diverse stakeholders. The focus is on income-generating technologies and essential factors behind successful scaling up of innovations, ultimately driving agricultural modernization and sustainability.

- Compiler: Joren Verbist

Modules

No modules