Bioslurry [Ethiopia]

- Creation:

- Update:

- Compiler: GERBA LETA

- Editors: Noel Templer, Julia Doldt, Kidist Yilma, Likissa Kurmana Dufera

- Reviewers: William Critchley, Rima Mekdaschi Studer

Siico biogaazi

technologies_6646 - Ethiopia

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Tolessa Tamiru

Farmer

Ethiopia

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Soil protection and rehabilitation for food security (ProSo(i)l)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Alliance Bioversity and International Center for Tropical Agriculture (Alliance Bioversity-CIAT) - Kenya1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

Nee

Comments:

Apart from supplying organic and inorganic nutrients to the plants and organic matter to the soil, bioslurry is alkaline in reaction and has liming effects.

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Farmers Research and Extension Group (FREG) [Ethiopia]

A Farmers Research and Extension Group (FREG) engages about 50 or more farmers in a kebele (lower administrative unit), with three sub groups of 17-20 each who live in a homogenous landscape. It is a local institution established for joint learning, piloting, and evaluating soil improvement technologies across the intervention …

- Compiler: GERBA LETA

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Bioslurry is a byproduct of the anaerobic process used for production of methane (biogas). It is derived from the manure used to feed the biodigester. Bioslurry is an organic fertilizer that serves as a replacement for chemical fertilizers, and also plays a pesticidal role.

2.2 Detailed description of the Technology

Description:

Bioslurry is a byproduct of the anaerobic process used for production of methane (biogas). It is derived from the manure and other organic materials used to feed the biodigester – which is central to a biogas plant. The biodigester is fed with thoroughly mixed livestock manure and water. For instance, a biodigester with a capacity of 8m3 requires manure from 8 cattle mixed with 20 litres of water daily. This allows consistent production of biogas, and bioslurry as a byproduct.

Bioslurry is used as an organic soil amendment that serves as an alternative to chemical fertilizers. It can also play a pesticidal role. Increasing the use of organic fertilizer can reduce the money spent on inorganic fertilizer by at least half. It also improves soil structure via the addition of organic matter. Essentially, the organic matter content of bioslurry is about 20-30%. Appropriate application of the bioslurry as organic fertilizer leads to more moisture retention in the root zone and improves crop resilience to adverse conditions. Usually, bioslurry is applied around homesteads where the biogas plant is sited where it produces energy and light for the household. The main functions of bioslurry are improving soil fertility, increasing crop production, and deterring invasion by various insects. Applying filtered liquid bioslurry to the crop supplies available liquid nutrients and manages crop infestation such as by fall armyworms and maize stalk borer.

Bioslurry is a replacement for chemical fertilizers. It is applied in two forms: liquid and dry forms. The liquid form is mainly used around the homestead, using a watering can or bucket. The dried form can more easily be carried to fields for application. Bioslurry as organic fertilizer is applied to vegetables and other perennial crops around the homestead, once during the growing season. The overall application rate by smallholders is not necessarily based on the recommendation rate per hectare but on the availability of the by-product. Row application is the efficient and effective use of resources in short supply. The rate of application to the specific parcel is on a decremental basis. The end users are pleased by its merit of increasing production, reducing investment costs on chemical fertilizers, improving soil structure and associated properties. They also like the way it makes constructive use of a byproduct that needs to be disposed of. Nevertheless, bioslurry is only available to those who invest in costly biogas plants which also require intensive labour input to collect cattle manure and fetch water.

2.3 Photos of the Technology

General remarks regarding photos:

A farmer makes ready dry bioslurry for use in the farm located far away from the point of production.

2.4 Videos of the Technology

Comments, short description:

Video on this technology was not documented.

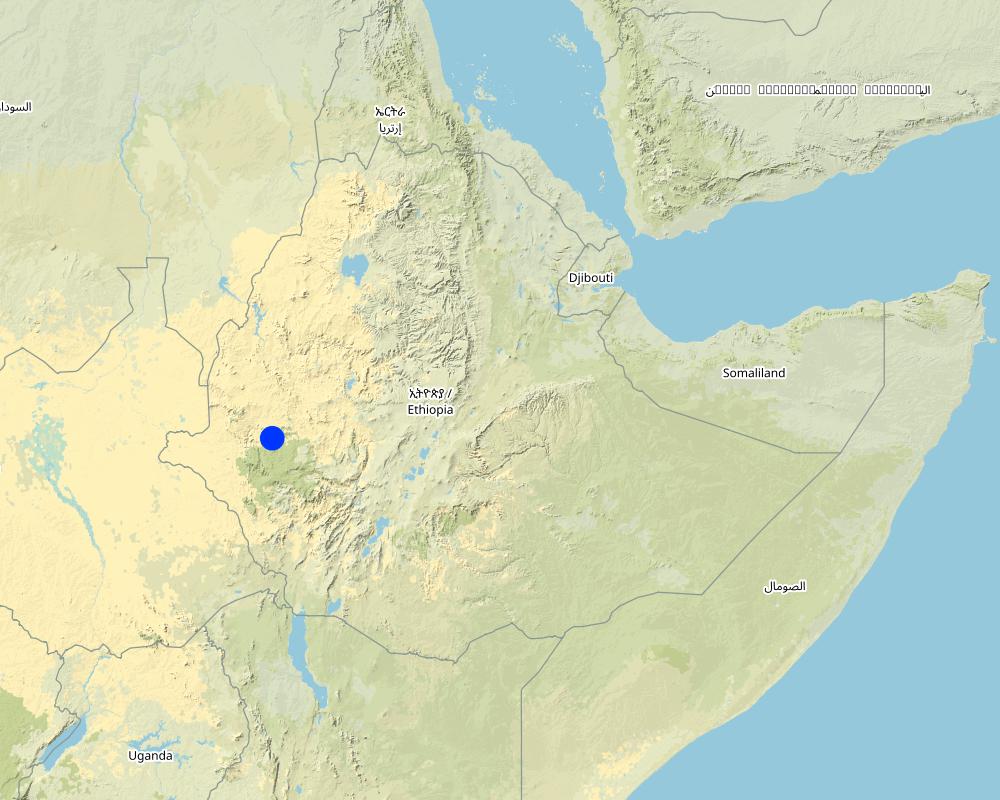

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Ethiopia

Region/ State/ Province:

Oromia

Further specification of location:

Adale-Bise Kebele, Mattu district

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Is/are the technology site(s) located in a permanently protected area?

Nee

Comments:

It is located at the homestead adjacent to the residence.

Map

×2.6 Date of implementation

Indicate year of implementation:

2020

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

The ISFM+ project of the GIZ has introduced it.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- protect a watershed/ downstream areas – in combination with other Technologies

- preserve/ improve biodiversity

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

Nee

Cropland

- Annual cropping

- Tree and shrub cropping

Annual cropping - Specify crops:

- cereals - maize

- cereals - sorghum

- Wheat

Tree and shrub cropping - Specify crops:

- avocado

Number of growing seasons per year:

- 1

Is crop rotation practiced?

Ja

If yes, specify:

Beans with maize.

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- No (Continue with question 3.4)

Land use mixed within the same land unit:

Nee

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

Comments:

Crop grown under rainfed conditions.

3.5 SLM group to which the Technology belongs

- integrated crop-livestock management

- integrated soil fertility management

- integrated pest and disease management (incl. organic agriculture)

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

- A3: Soil surface treatment

management measures

- M2: Change of management/ intensity level

- M5: Control/ change of species composition

Comments:

The effects of bioslurry on improving soil fertility are seen gradually. Six weeks later, the performance of the crop that grew under bioslurry surpassed that grown under chemical fertilizers.

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

- Ca: acidification

physical soil deterioration

- Ps: subsidence of organic soils, settling of soil

- Pu: loss of bio-productive function due to other activities

Comments:

According to the respondent farmer, after applying bioslurry to the degraded soil, the soil that used to be blown up quickly by the wind while tilling and was susceptible to water erosion forms a solid structure that tolerates wind and tolerates wind water erosion.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

- restore/ rehabilitate severely degraded land

Comments:

In addition to the role of complementing chemical fertilizer, bioslurry may have long-term positive effects on soil quality and crop growth via the accumulation of organic matter. It is also proved that bioslurry is rich in micro and macro nutrients.

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

The Photo clearly portrays where the feedstock is added; the biodigester produces methane gas; gas collection and energy production points, and the final collection pits for bioslurry are located. The photo is adopted from W. Critchley PPT presentation. The dimension of the different parts is variable based on the supply of feedstock and financial resources the land users have for investment.

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Biogas structure

Specify dimensions of unit (if relevant):

Structure with 8m3 digester

other/ national currency (specify):

ETB

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

53.12

Indicate average wage cost of hired labour per day:

200

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Constructing biogas structure | Anytime wanted |

| 2. | Supplying feedstock to the digester | On dial basis |

| 3. | Collect bioslurry via collection pits | when collection pits are filled and try to compost to transport the dry to remote farmlands. |

| 4. | Apply the slurry to the crop or the farm either in liquid or dry forms. | During planting and other time of the season depending, on the types of crop. |

Comments:

Construction of the structure needs various inputs such as stone/blocks, sand, cement, and accessories for taking the gas into the home, and generating light and heat energy for the households.

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labor | PDs | 10.0 | 200.0 | 2000.0 | 100.0 |

| Labour | Technician | Lump sum | 1.0 | 10000.0 | 10000.0 | |

| Equipment | PBC, Gate valve, plastic pipes, stove, bulbs | Lump sum | 1.0 | 6000.0 | 6000.0 | |

| Equipment | Spade | Nnumber | 1.0 | 300.0 | 300.0 | 100.0 |

| Equipment | Wheel barrow | Number | 1.0 | 1600.0 | 1600.0 | |

| Construction material | Cement | ton | 1.0 | 10000.0 | 10000.0 | |

| Construction material | Stone | m3 | 2.0 | 1500.0 | 3000.0 | 100.0 |

| Construction material | Sand | m3 | 8.0 | 500.0 | 4000.0 | 100.0 |

| Total costs for establishment of the Technology | 36900.0 | |||||

| Total costs for establishment of the Technology in USD | 694.65 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

ISFM+ project and District Water and Energy Office separately as well as jointly support the establishment of biogas/bioslurry technology.

Comments:

Material prices and labor costs are inconsistently changing. This goes with the economic instability and rousing inflation experienced in the country. Initial investment cost is priceless as compared to the benefit accrued from biogas/bioslurry overtime.

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Labor for collection of livestock drops, supply water, and drying the outputs. | Throughout |

| 2. | Maintenance of the malfunctioning structure and supply of biogas accessories. | Throughout |

Comments:

Access to accessories is an issue that farmers often encounter.

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Family labor to supply feedstock and collect the product. | PDs | 365.0 | 100.0 | ||

| Equipment | Accessories | Lump sum | 5.0 | 200.0 | 1000.0 | 50.0 |

| Total costs for maintenance of the Technology | 1000.0 | |||||

| Total costs for maintenance of the Technology in USD | 18.83 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

ISFM+ project and District Water and Energy office.

Comments:

The large share of maintenance/recurrent cost is the labor cost to collect manure and fetch water that is virtually covered by family labor. Therefore, the cost of family labor is not accounted for as cost.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Economic crisis and price volatility of the labor and materials.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Dry season: January to March, and wet season: June to September.

Indicate the name of the reference meteorological station considered:

Mettu

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

Comments and further specifications on topography:

The application of bioslurry is not limited by the topography.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

good

Water quality (untreated):

good drinking water

Water quality refers to:

surface water

Is water salinity a problem?

Nee

Is flooding of the area occurring?

Nee

5.5 Biodiversity

Species diversity:

- high

Habitat diversity:

- medium

Comments and further specifications on biodiversity:

The district is still endowed with diverse natural resources including the forest and the wetland areas.

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Relative level of wealth:

- rich

Individuals or groups:

- individual/ household

Level of mechanization:

- animal traction

Gender:

- men

Age of land users:

- elderly

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

Comments:

The farmer owns 8 ha of land.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

- individual, titled

Land use rights:

- individual

Water use rights:

- open access (unorganized)

Are land use rights based on a traditional legal system?

Nee

Specify:

He accessed farmland during the land redistribution program through the local government.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

The farmer observed a significant increase in crop yield per unit of land post the application of bioslurry. According to the farmer, the yield increment amounts to more than double the harvest that used to be gained via the use of chemical fertilizers.

crop quality

Comments/ specify:

A farmer communicated the improvement in the taste of the maize grain harvested from the farmland treated with bioslurry.

fodder production

Comments/ specify:

It increases biomass production and feed availability from crop residues.

fodder quality

risk of production failure

land management

Comments/ specify:

According to the land user, tilling the farmland treated by bioslurry is lighter than the other soil. Furthermore, it forms an aggregate that otherwise remains dusty on tillage without the use of organic fertilizer or the bioslurry.

Income and costs

expenses on agricultural inputs

farm income

Socio-cultural impacts

food security/ self-sufficiency

health situation

SLM/ land degradation knowledge

Ecological impacts

Water cycle/ runoff

water quantity

water quality

surface runoff

excess water drainage

groundwater table/ aquifer

Comments/ specify:

Not yet empirically measured.

evaporation

Comments/ specify:

As it promotes the growth of diverse plant species, it has positive effects on reducing evoration.

Soil

soil moisture

soil cover

soil loss

soil accumulation

soil compaction

nutrient cycling/ recharge

soil organic matter/ below ground C

acidity

Biodiversity: vegetation, animals

Vegetation cover

biomass/ above ground C

plant diversity

Climate and disaster risk reduction

emission of carbon and greenhouse gases

Specify assessment of on-site impacts (measurements):

The application of bioslurry has a positive impact on improving the fertility and productivity of the farmland. However, comprehensive data is desirable to quantify the different attributes included in this particular questionnaire.

6.2 Off-site impacts the Technology has shown

water availability

reliable and stable stream flows in dry season

Comments/ specify:

As the technology is not widely adopted and measured its impact is negligible in this regard.

downstream flooding

downstream siltation

Comments/ specify:

Reduces the runoff of soil and water because of good ground cover and high biomass production.

damage on neighbours' fields

Comments/ specify:

As it arrest the downstream runoff, it reduces the damage it may imposes on the adjacent fields.

Specify assessment of off-site impacts (measurements):

The application of bioslurry has positive off-site impacts on the adjacent wetlands and other ecosystems.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | moderately | |

| seasonal temperature | dry season | increase | moderately |

| annual rainfall | decrease | well | |

| seasonal rainfall | summer | decrease | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

very positive

Comments:

During the establishment phase, the farmer hesitates to engage as the cost is on the higher side.

6.5 Adoption of the Technology

- single cases/ experimental

If available, quantify (no. of households and/ or area covered):

The technology piloted by three farmers in a kebele.

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

The project directed almost all the implementers through partner government staff.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Nee

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Improve soil fertility |

| Increase production per unit of land |

| The process allows for cleaning the environment, as cattle manure and urine are collected and safely disposed of or used as feedstock to the biogas structure. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Allows the farm to retain moisture and nutrients, keep the crop vigorous, and become resilient to adverse conditions. |

| It creates employment opportunities for the member of the family farmers. |

| Liquid slurry deters insect pests from the farm and the crop. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Labor-intensive technology for its production and application to the farm. | Aware of family members and engaged them in the production and uses of slurry. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| High initial investment cost. | Provide support via the project as well as relevant government organizations such as water and energy, also through strengthening cost sharing with the end user. |

| As the production per structure is relatively low, the rate and frequency of application have not yet worked out. | Need follow-up, documentation, and defining the right amount and frequency of application to crop and the farm. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

Two (husband and wife)

- interviews with land users

A farmer only.

- interviews with SLM specialists/ experts

One Woreda expert.

When were the data compiled (in the field)?

08/02/2023

7.2 References to available publications

Title, author, year, ISBN:

Bioslurry: A supreme fertilizer. Warnass, L. 2014. ISBN: 978-90-70435-07-3

Available from where? Costs?

https://www.academia.edu/83905083/Bioslurry_A_Supreme_Fertilizer

7.3 Links to relevant online information

Title/ description:

Bioslurry = Brown Gold? A review of scientific literature on co-product of biogas production.

URL:

https://www.fao.org/3/i3441e/i3441e.pdf

7.4 General comments

Some questions in the questionnaire are not directly related to the technology/practice. Sketching also needs technical knowledge and skills as it is demanding for inexperienced individual in drawing.

Links and modules

Expand all Collapse allLinks

Farmers Research and Extension Group (FREG) [Ethiopia]

A Farmers Research and Extension Group (FREG) engages about 50 or more farmers in a kebele (lower administrative unit), with three sub groups of 17-20 each who live in a homogenous landscape. It is a local institution established for joint learning, piloting, and evaluating soil improvement technologies across the intervention …

- Compiler: GERBA LETA

Modules

No modules