There is not a lot of available land to grow fodder grass in the narrow valleys of the mountain rivers of Rasht. So people use slopes in highlands with high and thick grass cover - first as haymaking (in June, July, mow the grass, dried, July-August- lowered hay) and then in September allow to graze cattle. The common spread in the last 20-25 years, method of descent sheaves of hay takes a lot of time and causes great damage to slopes vegetation and soil cover.

It was as follows: 5-6 big branches of trees and shrubs, knot like sleigh on which the 20-30 sheaves of hay (each of them is 6-7 kg). Then drag on the down-slope. This process each year and many times was repeated by every family (each household lowers minimum 400-500 sheaves of hay. "Sleigh" left along the slope consequence devoid of vegetation and topsoil. Through which at spring the flow of water is concentrated, with time there formed gullies. Now, the cutting of trees, destruction of vegetation and soil down the hill in k.Shulmak stopped since descent sheaves of hay from alpine slopes areas down to the foot is carried through the air using a special device - hay carrying mechanism. One person knot each sheave with twine, a special metal hook catches, strung on steel wire and alternately releases. Under the influence of its own gravity, and due to a good tension steel wire, bundles rapid slide down. In the foot, the second person takes them. In one hour they can descend from an elevation of more than 1000m 100-150 sheaves of hay (before it took 3-5 days). Hay is immediately loaded into trucks and transported home.

This technology decreases the human made degradation of natural resources (mountain forests and soil on the slopes) by facilitating the process of hay descend for winter cattle, through the application of advanced resource-saving technologies.

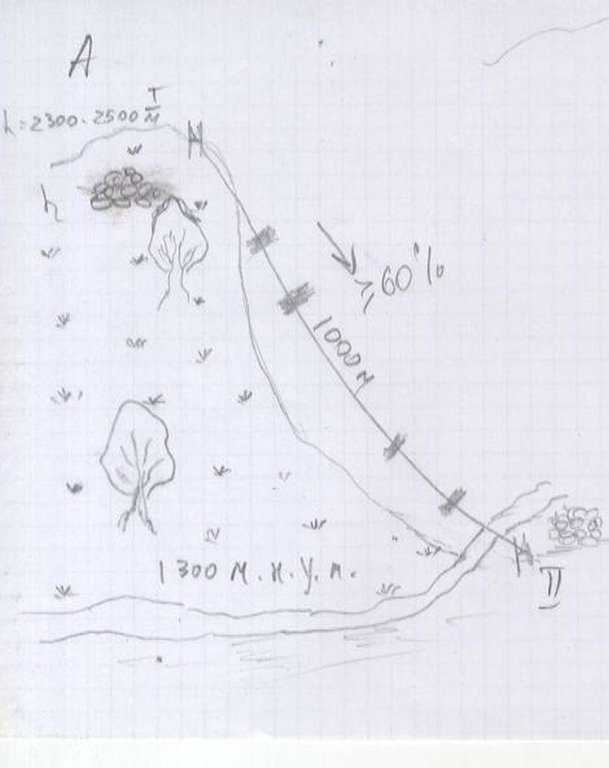

This technology was also used 30-40 years ago, but the footholds were wooden, and all were destroyed and farmers were unable on their own to restore them. PO "Azal" has modified them, made entirely of metal and more durable. For the construction of the device of air transportation of hay, with financial support from BMZ all the necessary building materials were delivered and they carry out construction supervision. For each of the foothold (made of metal pipes with diameter 70-80mm) - preparing the site - 2 x 2.5m (x 1m depth of cement, sand, gravel). Pull between them steel wire is sometimes 1000-1200m long D 3-3.5mm it should be solid, without knots for good sliding sheaves down. Depending on the topography (slope elevation and steepness), hay carrying mechanism are constructed in different ways: on the straight slopes installed one long, if the slope has a step or hayfields are far from the mechanism consist of two step parts and all the sheaves first pull on the middle point, and then by using the second wire send hay sheaves further down. Such mechanism is two time intensive. In total for 2012 in jamoat Rahim-zoda nine of them were constructed.

The center of Rash district - Garm is 230 km far from Dushanbe. From Garm to the Shulmak village another 25 km. It refers to the jamoat Rahim -zoda, and is closely located to the leskhoz- "Kamarov" (4-5 km), at 1300 m a.s.l. The average annual rainfall is more than 800 mm, winter is long and snowy. Summer in the narrow valleys of mountain rivers is dry but in the highlands at this time cool and creates favorable conditions for germination of thick and high grass cover.

The main income-generating sector is livestock, in second place fruit production. Therefore it is very important for farmers to have enough storage of fodder for a long stall period (4.5-5 months, from November 20 until April). Sometimes the feed end in winter and farmers are forced to buy them very expensive (summer sheaf is -6s) or slaughter the cattle and sale very cheap. So hay storage for winter is one of the most important events in the village. The presence of a sufficient amount of food at the time of confinement also reduces the load on the near village pasture - because the greater the supply of food for the winter, the later in the spring they will bring the cattle on the mountain slopes and less soil will be degraded.

Location: Rasht district, jamoat Rakhim-zoda, v. Shulmak., Tajikistan, DRS, Tajikistan

No. of Technology sites analysed:

Spread of the Technology: evenly spread over an area (approx. 1-10 km2)

Date of implementation: 10-50 years ago

Type of introduction

Technical specifications

Author: Shokhumorova Pariso

depending on the topography of the slopes the hay carrying mechanism can be simple straight from up to down, or if hayfields are far, it has to do this mechanism consisting of two parts

Location: Tajikistan. Rasht district, jamoat Rahim- zodа k.Shulmak Date: 25.04.2015 Technical knowledge required for field staff / advisors: moderate (he should be able to calculate the length of the cable, the number of necessary cement, etc.) Technical knowledge required for land users: moderate (they have to have some skills to gain a sustainable design) Main technical functions: improvement of ground cover, stabilisation of soil (eg by tree roots against land slides), increase of biomass (quantity) Secondary technical functions: improvement of topsoil structure (compaction), increase in organic matter, increase of infiltration, increase / maintain water stored in soil, promotion of vegetation species and varieties (quality, eg palatable fodder) Structural measure: foothold (iron pipes) on top and foot of slopes Vertical interval between structures (m): 1000m Width of bunds/banks/others (m): D=70-80mm Length of bunds/banks/others (m): 8m Structural measure: Steel wire stretched between them. Vertical interval between structures (m): 1000m Width of bunds/banks/others (m): D=2-3,5mm Length of bunds/banks/others (m): 1000-1200m Construction material (stone): Gravel, sand Construction material (concrete): cement Construction material (other): Iron pipe D70- 80mm; steel wire D = 2-3,5mm Major change in timing of activities: Job that required time (100 sheaves of hay took 3-5 days) is now done in an hour |

|||||||||||

| Specify input | Unit | Quantity | Costs per Unit (Somoni) | Total costs per input (Somoni) | % of costs borne by land users |

| Labour | |||||

| Labour | 1.0 | 255.9 | 255.9 | 100.0 | |

| Equipment | |||||

| Machine use | 1.0 | 70.0 | 70.0 | ||

| Animal traction | 1.0 | 33.6 | 33.6 | 100.0 | |

| welding apparatus | 1.0 | 21.0 | 21.0 | 100.0 | |

| Gas for welding apparatus | 1.0 | 11.6 | 11.6 | ||

| Construction material | |||||

| steel wire D=2-3,5mm | 1.0 | 96.6 | 96.6 | ||

| thick iron pipes,D=70-80mm | 1.0 | 126.0 | 126.0 | ||

| cement | 1.0 | 151.3 | 151.3 | ||

| gravel, sand | 1.0 | 31.5 | 31.5 | ||

| Other | |||||

| iron wire D=5-6mm for hooks | 1.0 | 16.8 | 16.8 | ||

| solidol | 1.0 | 3.0 | 3.0 | 100.0 | |

| Total costs for establishment of the Technology | 817.3 | ||||

| Specify input | Unit | Quantity | Costs per Unit (Somoni) | Total costs per input (Somoni) | % of costs borne by land users |

| Labour | |||||

| Labour | 1.0 | 30.9 | 30.9 | 100.0 | |

| Other | |||||

| iron wire D=5-6mm for hooks | 1.0 | 1.9 | 1.9 | 100.0 | |

| solidol | 1.0 | 1.5 | 1.5 | 100.0 | |

| Total costs for maintenance of the Technology | 34.3 | ||||

freed time for other types of profitable work

all of the obstacles on the descent (time, etc.) are eliminated

Hay lossless quickly stored., Then the fodder security is provided for cattle

It excludes the hard work -the long distance descent of hay from the highlands

These free days, they can relax in the family. Goin to the cinemai etc.

The descent became very lightweight, so men neighbors can now find the time to help an elderly neighbor or women get the hay down etc

many days they spent on the trigger of hay, they can now spend an amendment on health, or the acquisition of necessary goods for their livelihood as well as their education

With the reduction of number of artificial gullies and places devoid of vegetation, decrease runoff

the destruction of topsoil is decrease

Each descent of hay on the branches, disturbed topsoil, and later it washed off by rain

reduced trampling

By reducing trampling and destruction of vegetation biomass increases

With less trampling increased number of plant species

The absence of trampling leads to the restoration of biodiversity

If less trampling, the more insects and soil fauna will be safe

The absence of trampling leads to the restoration of biodiversity

The destruction of vegetation and soil down the slope is stopped now