-The Zero-Waste Pig Farm or Moo Lum is the integrated management of pigs in pens with the use of microorganisms that lead to the safety of pork products. This technique has become beneficial, as the pig waste can be used as organic fertilizer that produces no pollution to the community.

Pig farming in a community generally causes unwanted waste products: pig manure with its strong odor, and polluted water. This causes conflict about the use of land in the community too. The management of the ‘Zero-Waste Pig Farm’ or ‘Moo Lum’ is an alternative practice which greatly reduces the environmental problems caused by traditional pig farming. There are two key elements of the Zero-Waste Pig Farm or Moo Lum management: one is the pig farm and the other is the waste.

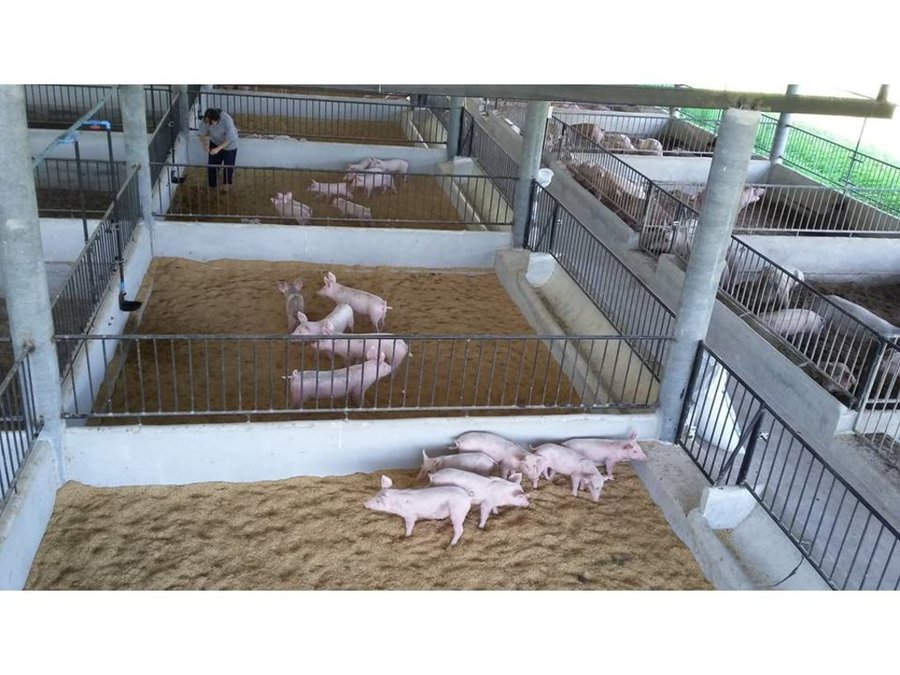

A. Pig farm management: housing and feeding.

Housing: pig houses should be built in dry areas, not-to-be-flooded with rainwater in the rainy season. Locally available materials should be used, such as bamboo, grass, etc. The pig house should have good ventilation. Pig pens, on the other hand, should be on bare soil with no cement. In each pig pen there should be a pit, 60-70 cm deep, while the floor of the pig pen one should be covered with rice husks, sawdust or coconut coir. Feeding: Pig raising involves pig food management with concentrated and fermented foods. The raw material is selected from non-chemically treated materials that have gone through processes with use of herbal powder mixed with bio-fermented water. This is the technique to promote animal health and to prevent animal diseases. The pig types in the farm are the popular species of Duroc CLD, Landrace and Large White, from when they are weaned (at about 1 month old).

B. Waste management: Lay the husks or any organic materials on the bottom of the pit in the pen, divided into two layers (about 30 cm thick for each layer), then put salt and bio-fermented solution. Each week, apply the bio-fermented solution to improve the efficiency of the decomposition of pig waste. After a cycle of pig feeding one will get an amount of compost from the pigpen hole. The objective of the zero-waste pig farm or Moo Lum technology is to produce safe pork products through the production process of an environmentally friendly animal farm without pollution and then obtain quality pig manure compost to be used quite beneficially in the organic production process. The zero-waste pig farm or Moo Lum technology processes are as follow:

1. Build the pig houses on an unfloodable area with good ventilation.

2. Build a stall about 4 x 4m wide which can hold 8 pigs.

3. Prepare the stall.

4. Choose the breeds of pigs that are popular.

5. Select the food for the pig obtained through non-chemical processes.

6. Apply bio-degradable pesticides on the floor. Feed the pigs with bio-fermented water. When the pigs get sick, they are treated according to the symptoms with herbal medicine.

7. Take care of them.

The benefit as commented by the users of this technology are as follows:

The user can establish a pig farm in a community with no odour and no flies swarming around. The organic fertilizer from pig manure will improve the quality of the soil in the area, which will benefit the user even further. Another saving is reduced labour from the various cleaning operations needed under conventional management.

However, there are some limitations, as some processes of the technology take unusually longer time. The pork products are not widely known as a ‘safe pork products’ as there is no standard set for such farming by the government. Finally, there is often a shortage of pig food; there should be more production of pig food in the community.

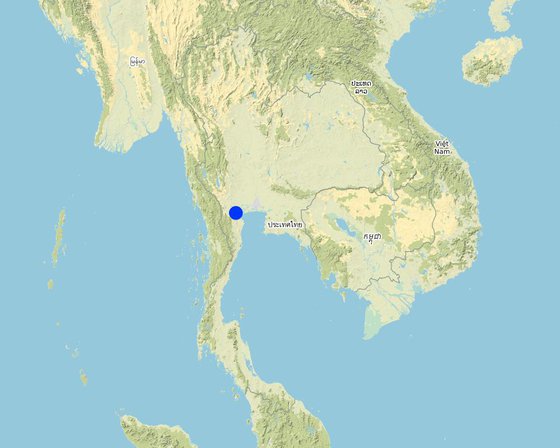

Location: Tambon Don Rae Muang District Ratchaburi province, Ratchaburi, Thailand

No. of Technology sites analysed:

Spread of the Technology:

In a permanently protected area?:

Date of implementation: 1969; more than 50 years ago (traditional)

Type of introduction

| Specify input | Unit | Quantity | Costs per Unit (Thai Baht (THB)) | Total costs per input (Thai Baht (THB)) | % of costs borne by land users |

| Labour | |||||

| 1Moo Lum management | man | 210.0 | 300.0 | 63000.0 | 100.0 |

| 2.Moo Lum food management | man | 60.0 | 300.0 | 18000.0 | 100.0 |

| 3.Moo Lum waste management | man | 300.0 | 300.0 | 90000.0 | 100.0 |

| 4.Housing | man | 120.0 | 300.0 | 36000.0 | 100.0 |

| Construction material | |||||

| 1.Housing material | โรง | 1.0 | 84000.0 | 84000.0 | 100.0 |

| Other | |||||

| 1.pig food | animal | 90.0 | 3800.0 | 342000.0 | 100.0 |

| 2. breeding pig | animal | 90.0 | 1500.0 | 135000.0 | 100.0 |

| Total costs for establishment of the Technology | 768'000.0 | ||||

| Total costs for establishment of the Technology in USD | 24'000.0 | ||||

| Specify input | Unit | Quantity | Costs per Unit (Thai Baht (THB)) | Total costs per input (Thai Baht (THB)) | % of costs borne by land users |

| Labour | |||||

| 1.Moo Lum management | man | 210.0 | 300.0 | 63000.0 | 100.0 |

| 2. Moo Lum food management | man | 60.0 | 300.0 | 18000.0 | 100.0 |

| 3. Moo Lum waste management | man | 300.0 | 300.0 | 90000.0 | 100.0 |

| Total costs for maintenance of the Technology | 171'000.0 | ||||

| Total costs for maintenance of the Technology in USD | 5'343.75 | ||||

-

Better due to the use of quality manure from Moo Lum

More diversity of markets

More value-added products

Suitable land management

More intensive care

Sustainable production

Good health

Well utilized land use

No odor pollution

The pig waste is used as manure/ compost locally.

Soil improvement by using manure/ compost from the pig farm

Using manure compost for soil improvement

Reduced bad odor from the farm