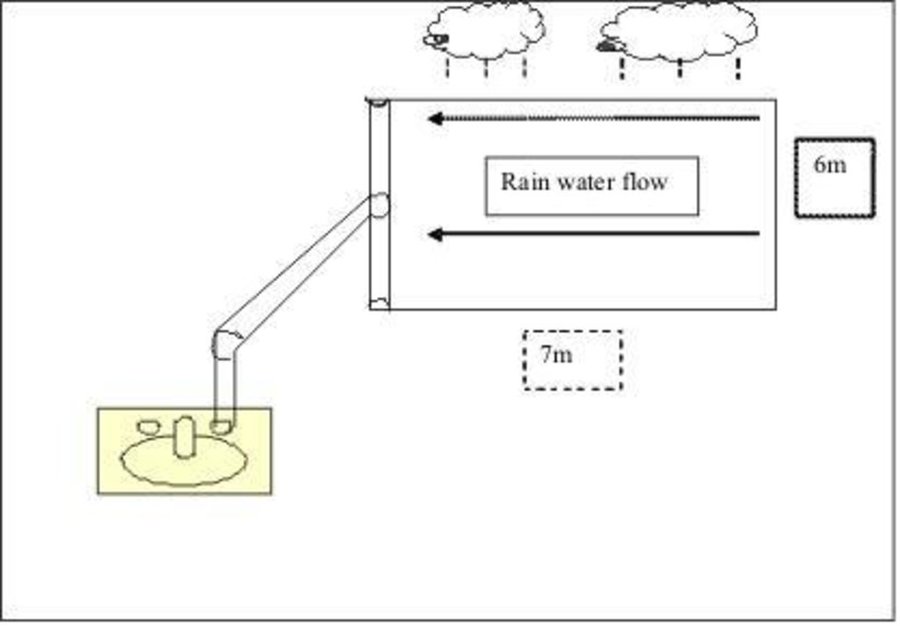

A roof of galvanised iron (corrugated iron) with the dimensions 7 x 6m is constructed on a support of gum poles (see photos). The roof catches the rain. The rain water flows over the roof into pipes at the rear end of the roof (sloping side) into an underground conical water tank. The tank is made of bricks and mortar. The underground tank serves two key roles: i) it stores water for use during the dry spells or times of no rain; and ii) the tank keeps the water cool in this hot environment. The technology is most preferred for so-called ‘lands’ areas, to provide household drinking water. On average, these lands are distant from water sources (e.g. 2-15 km). Other benefits of storing rainwater include less pressure on natural water ponds, but this would be a secondary concern

Water is critical for human consumption and needed around the home. The cool water is effective in quenching the thirst; it reduces labour time to collect water thus freeing time to concentrate on other farm activities. The water is mainly for household drinking and household chores like washing. Some is used as drinking water for chickens and for the animals used for draught power (e.g. donkeys during ploughing). The units are for use by individual farmers and thus restricted to individual households. The owner or the farmer has exclusive rights to the use of the water. Some farmers indicated that, in times of no rain, or before the first rains, they collect water from the village in drums, and pour it into this underground water tank, thus using it as a reservoir. They especially like the persistent coolness of water stored in the underground tank.

The technology is for rainwater collection in four villages. Rainwater that flows over the roof is collected, for example, on galvanised iron roofs. The water then runs through gutters and a pipe to the underground water tank. To build the underground tank, the ground is excavated, to about 2m deep and about 3m wide. Within this hole, a drum-like feature is built with concrete bricks and mortar. After the wall of the tank is complete, it is then lined with mortar from the inside, and the base is also lined to form the completed tank. It is then sealed at over most of the surface leaving an opening with a lid. This opening is large enough for a man to enter for occasional cleaning of the groundwater tank. Thus the system comprises a roof, for collecting rainwater, and an underground tank for storing it.

The environment is semi-arid and seasonal rainfall dominates during the summer months of October to April. People depend on nearby boreholes for water in the lands areas or have to travel to the village (about 2-5km away on average, but can be up to 15km) to fetch water. Most boreholes are either privately owned or communal and water is rationed to about two drums per week or even fortnightly. Most of the borehole water in the area is brackish. Thus roof rainwater (which is fresh) acts as the preferred alternative source of water. The underground tank, once full, is equivalent to 110 drums. Most normal rain events fill the tank, and the water remains in use till the next rainy season, which was found to be the case at all four pilot sites visited. Thus the rainwater catchments systems offer water security in the lands areas; water of very good drinking quality (sweet taste, cooler).

Location: Central District, Boteti area, in Central District of Botswana, Botswana

No. of Technology sites analysed:

Spread of the Technology:

In a permanently protected area?:

Date of implementation: 10-50 years ago

Type of introduction

| Specify input | Unit | Quantity | Costs per Unit (Pula) | Total costs per input (Pula) | % of costs borne by land users |

| Labour | |||||

| labour | ha | 1.0 | 12.5 | 12.5 | 100.0 |

| labour by gov (8 person days) | ha | 1.0 | 500.0 | 500.0 | |

| Construction material | |||||

| sand, cement, concrete block | ha | 1.0 | 1500.0 | 1500.0 | 100.0 |

| Total costs for establishment of the Technology | 2'012.5 | ||||

| Total costs for establishment of the Technology in USD | 251.56 | ||||

| Specify input | Unit | Quantity | Costs per Unit (Pula) | Total costs per input (Pula) | % of costs borne by land users |

| Labour | |||||

| labour | ha | 1.0 | 12.5 | 12.5 | 100.0 |

| Total costs for maintenance of the Technology | 12.5 | ||||

| Total costs for maintenance of the Technology in USD | 1.56 | ||||

Quantity before SLM: 0.15 t/ha/y

Quantity after SLM: 0.195 t/ha/y

30% increase due to more time to manage crops better e.g. weeding

mainly chickens and small stock

Quantity before SLM: 40%

Quantity after SLM: 10%

more time on farm

water year round

Quantity before SLM: 5%

Quantity after SLM: 90%

at construction phase only

Quantity before SLM: 3%

Quantity after SLM: 25%

from horticulture, chickens etc

Quantity before SLM: 5%

Quantity after SLM: 90%

poor cannot afford it

no time lost in collecting water afar

Quantity before SLM: 5%

Quantity after SLM: 35%

better yields with more on-farm time

Quantity before SLM: 5%

Quantity after SLM: 40%

the water is better than in region

Quantity before SLM: 6%

Quantity after SLM: 50%

uplifting of the disadvantaged

Quantity before SLM: 4%

Quantity after SLM: 50%

conflicts exist over boreholes

improved water provision, not affordable for the poor (unless subsidized)

Many educational tours made on these demonstration sites. Fresh rainwater is good for health compared to borehole (salty) water.

Quantity before SLM: 5%

Quantity after SLM: 80%

water year round

not salty/saline, to clean roof and tank annually (temporarily)

Quantity before SLM: 1%

Quantity after SLM: 90%

resource from previous year used

Quantity before SLM: 1%

Quantity after SLM: 90%

underground water tank, sealed

Quantity before SLM: 1%

Quantity after SLM: 90%

clean technology

Quantity before SLM: 2 drums/we

Quantity after SLM: 42drums/we

all this water saved due to technology