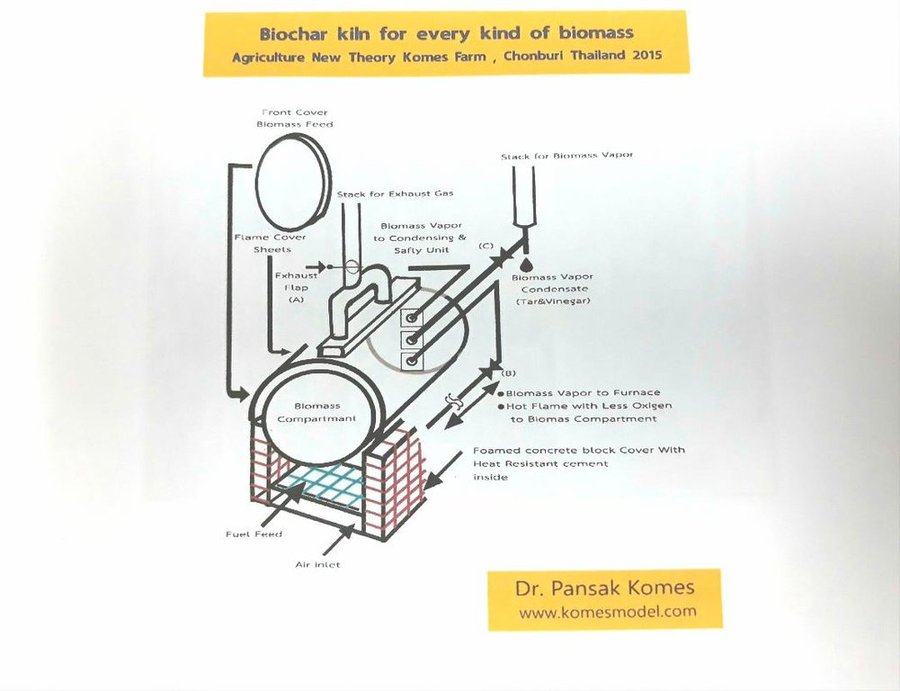

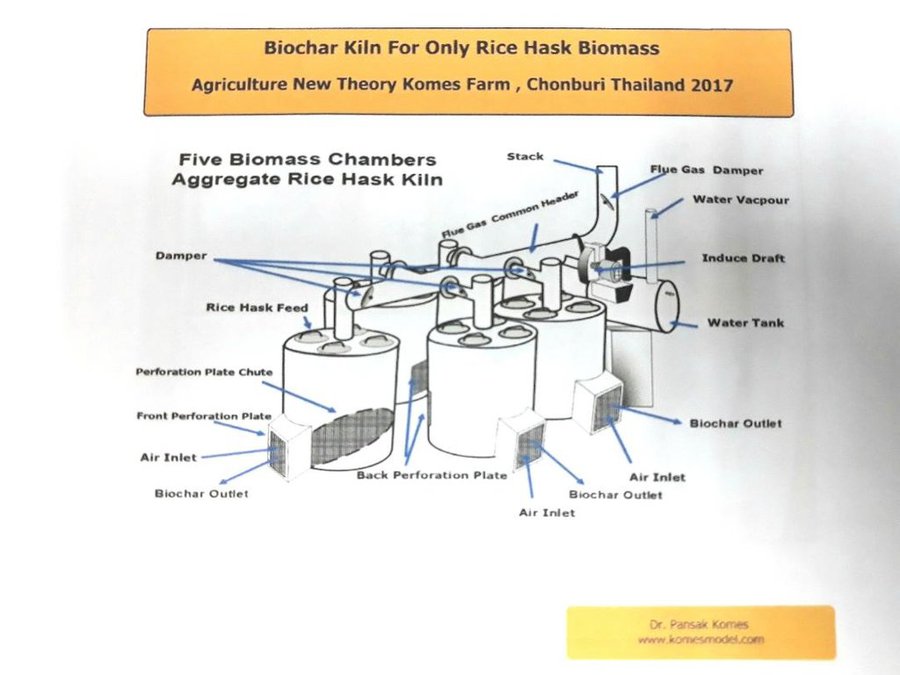

Biological charcoal or biochar is porous charcoal obtained from biomass. To obtain biochar, biomass is loaded into a kiln that can be heated to very high temperature (higher than 500 degrees Farenheit). The biomass goes through a process of biodegradation called pyrolysis. After a few hours, this biomass is converted into a coal-like substance, which farmers can use as a soil amendment. Biochar is an alternative way to solve the problems of the environment such as healthy soils, food production and global warming reduction.

Such charcoal production is a technology that can be conducted from the level of farmers to the level of industries. Lehmann and Joseph (2009) collated research work related to the properties of biochar. It was found that biochar had a property of neutrality to alkalinity. It is porous, can hold water and has a composition of elements such as phosphorus, potassium and calcium - but especially carbon. Their findings indicated that biochar can absorb nutrients well, can withstand biological and chemical decomposition and promote activities of microorganisms in the soil. In addition to this biochar, through its positive effect on carbon sequestration, is another way to reduce the emission of carbon to the atmosphere - which is the cause of climate change through the greenhouse effect. Carbon is effectively locked in the biochar and not released. Much research has found that biochar is suitable for agricultural application. It improves soil properties physically, chemically and biologically. To work with biochar, we need a biochar kiln to produce it.

Location: Bor Kwang Tong District, Chonburi province, Chonburi province, Thailand

No. of Technology sites analysed: 2-10 sites

Spread of the Technology: evenly spread over an area (approx. 1-10 km2)

In a permanently protected area?: No

Date of implementation: less than 10 years ago (recently)

Type of introduction

| Specify input | Unit | Quantity | Costs per Unit (n.a.) | Total costs per input (n.a.) | % of costs borne by land users |

| Labour | |||||

| Finding the area to install the set of the biochar-producing stove, make area adjustment for the base plate and the supply line, and the drainage course | person | 10.0 | 35.0 | 350.0 | |

| Building the shelf for keeping Feed Stock and keeping the biochar | person | 10.0 | 35.0 | 350.0 | |

| Building the electrical system for using the lighting equipment and Service Water | person | 0.06 | 33.0 | 1.98 | |

| Building equipment parts of the biochar-producing stove, namely dust & exhaust -trapping equipment and the equipment assembling work, medium-levelled labor | person | 0.86 | 16.6 | 14.28 | |

| Equipment | |||||

| Building equipment parts of the biochar-producing stove, namely dust & exhaust -trapping equipment and the equipment assembling work, low-levelled labor | person | 0.86 | 35.0 | 30.1 | |

| Equipment costs for building biochar-producing stoves(Biochar klin for every kind of biomass together with Biochar klin for only rice husk biomass totalling 1 set),namely 200-liter used tanks, Induce Draft Fan, Electric Water Pump, High pressure water spray, Electric Wood Saw and other miscellaneous equipment | person | 0.03 | 400.0 | 12.0 | |

| Costs of materials which are iron ornaments, namely iron pipes, screws-nuts and others totaling 40 items for building the stove for 1 set | person | 0.03 | 599.6 | 17.99 | |

| Total costs for establishment of the Technology | 776.35 | ||||

| Total costs for establishment of the Technology in USD | 24.34 | ||||

| Specify input | Unit | Quantity | Costs per Unit (n.a.) | Total costs per input (n.a.) | % of costs borne by land users |

| Labour | |||||

| Preparing Feed Stock , transporting biomass materials and products | person | 0.06 | 2200.0 | 132.0 | |

| Equipment | |||||

| Miscellaneous equipment and tools for operation | set | 0.03 | 333.3 | 10.0 | |

| Plant material | |||||

| Firewood scraps can be bought locally(including transportation expenses) | kg | 333.3 | 0.03 | 10.0 | |

| Raw rice husk (including transportation expenses) | kg | 333.3 | 0.06 | 20.0 | |

| Other | |||||

| Yearly Inspection and Maintenance | time | 33.3 | 1.3 | 43.29 | |

| Electrical energy and tap water | time | 3.33 | 3.3 | 10.99 | |

| Total costs for maintenance of the Technology | 226.28 | ||||

| Total costs for maintenance of the Technology in USD | 7.09 | ||||