Agriculture, livestock herding and tourism are the major contributors to Gilgit Baltistan economy. The arable land in this region is limited (only 2%) and more than half of which is still barren due to unavailability of irrigation water supplies. The reported dependency of irrigated areas on glacier fed irrigation is more than 90 percent, which now have been fluctuating due to changing climate. This region has been experiencing drastic changes in climate which resulting into lowering of glacier and water related disasters leading towards discontinuity of irrigation water supplies. The electrical power energy options are limited as well as unreliable and in situ replacements are very expensive.

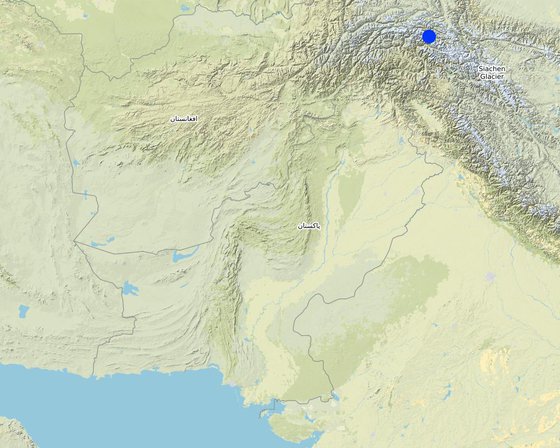

The technological package was applied in arid climate at an elevation ranging from 2340m to 4877 m above sea level. Khyber is located at 36.56o N latitude and 74.79o E longitude. The area receives 150-200 mm annual rain-fall. The population of Khyber village is 1200 residing in 150 houses. Almost 46 percent of population is salaried, 20 percent own business and roughly 19 percent engaged with farming to earn bread and butter for families. The average landholding per household is 3.8 acres out of which 1.25 acre is cultivable waste due to insufficient water supplies and local labor.

To address the above issues, the Indus Basin Initiative (IBI) of International Centre for Integrated Mountain Development (ICIMOD) through its a consortium of local partners including Pakistan Council of Research in Water Resources (PCRWR), Mountain Agriculture Research Centre (MARC) and WWF-Pakistan has been demonstrating the alternative agricultural water management package of practices in lifting water for irrigation using Hydro ram pump. This study also presents the findings based on the experiment/demonstration and testing conducted in the pilot. The pilot site is located in Khyber village of Hunza, Gilgit Baltistan.

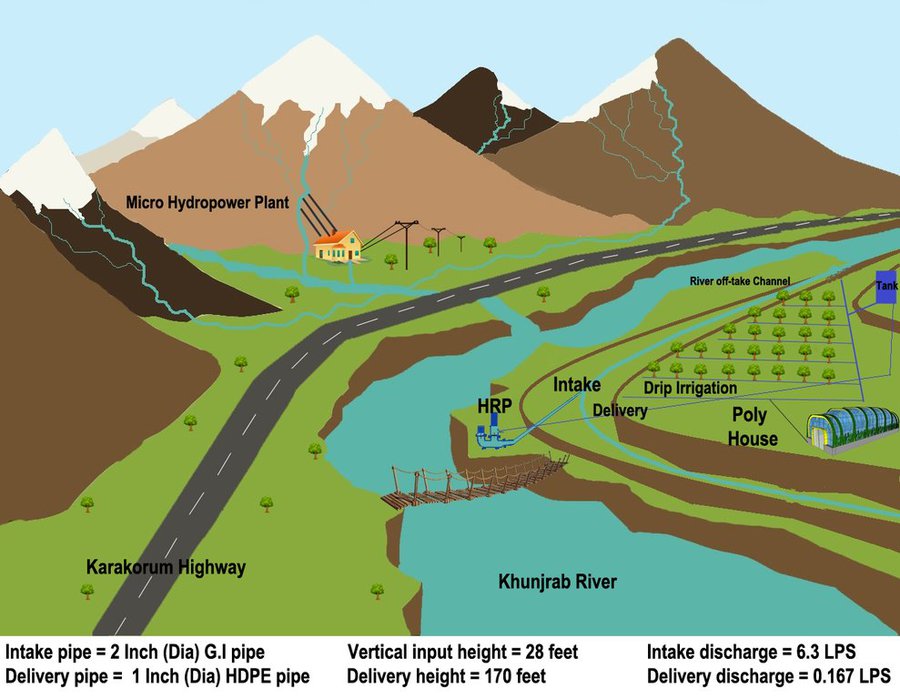

The pumping unit comprises a hydro ram pump (which is a zero carbon emission technology and needs no electricty to run, and it is locally customized having 1 inch/25mm out-take pipe) to lift water from a contour channel originating from the Khunjrab River and to carry the water to storage tanks (4000 liters) made up of plastic that has been placed upslope at 175 feet (53,3 m) vertical height from the river. The water from the storage tanks was supplied to alley cropping (apple sapling rows and vegetables rows) through pressure compensating drip irrigation system. The pumping capacity of the pump is 10.2 liters/minute, which is irrigating around 350 apple plants and vegetable rows at 2.5 acre (1ha). The storage tank was kept 45 feet (13,5 m) vertical height from the orchard field. Plan to plant distance and row to row distance of apple was maintained at 15 feet (4,6 m) and 20 (6 m) feet respectively. Drip irrigation system was established for each apple plant, as well as vegetables rows. Pits were constructed for planting apples and later they served also as water harvesting pits /check basins. Gilgit Baltistan chapter of WWF-Pakistan mobilized the local community, while PCRWR and MARC provided technical support to the Khyber Community in establishment of this pilot site. The community youth provided voluntary support during the land preparation, plantation and installation of hydro ram pump as well as drip irrigation system and the uphill storage tanks.

The cost of a complete package including hydro ram pump with accessories, storage tanks, intake and distribution systems, drip irrigation, apple plants and operational expenses for the site was US$ 25, 865 for 2.5 acre (1ha) of land. Women Organization of Khyber village takes care of the maintenance of technological package (fortnightly desilting of drip irrigation and storage tanks and annual repair of hydraulic ram pump). The fruit production has not yet started as it is a newly established farming site. However, seasonal vegetable farming has just started. The produce is small as soil fertility is still building up. Currently, the grown vegetables are being sold or used in the village at household level. However, with higher yield in future, the total income from the farm produce (currenty vegetables only) would be divided equally among the participating 150 households of Khyber Village. A comprehensive cost benefit analysis study has been conducted. It has been envisioned that apple orchard would mature in 4 to 5 years in cold climate of Gojal. By the 6th year, the farm would produce enough to the reach break-event point. The vegetable production has started now and the envisioned annual income is 15,000 PKR (almost 111 USD, if 1 USD=135 PKR).

The community welcomed the new technology and is now planning to outscale it in other areas to bring more land under cultivation. The women organization in the pilot site are positive about the less labourous agricultural activities and foresee to extend the alley cropping under drip irrigation to the rest of 7.5 acres, too. This technology is being dessiminated to different stakeholders including practitioners, policy and decision makers, academia, researchers and local farming communities. For this purpose, exposure field visits and farmers' field days have been arranged by the implementation partners.

Location: Khyber Village, Hunza District, Gilgit Baltistan, Pakistan

No. of Technology sites analysed: single site

Spread of the Technology: applied at specific points/ concentrated on a small area

In a permanently protected area?: Yes

Date of implementation: 2018; less than 10 years ago (recently)

Type of introduction

| Specify input | Unit | Quantity | Costs per Unit (USD) | Total costs per input (USD) | % of costs borne by land users |

| Labour | |||||

| Plumbing and technical workers | 1 | 1.0 | 775.0 | 775.0 | 33.0 |

| Installation charges | 1 | 1.0 | 968.0 | 968.0 | |

| Equipment | |||||

| Ram Pump & Accessories | 1 | 1.0 | 8526.0 | 8526.0 | |

| Drip Irrigation | 1 | 1.0 | 5813.0 | 5813.0 | |

| Off-seasonal vegetable tunnel | 1 | 1.0 | 4715.0 | 4715.0 | |

| Plant material | |||||

| Apple tree saplings (lumb sum) | 1 | 1.0 | 3165.0 | 3165.0 | |

| Fertilizers and biocides | |||||

| Compost (250 kg) | 1 | 250.0 | 0.12 | 30.0 | 100.0 |

| Other | |||||

| Feasibility study | 1 | 1.0 | 1873.0 | 1873.0 | |

| Total costs for establishment of the Technology | 25'865.0 | ||||

| Total costs for establishment of the Technology in USD | 25'865.0 | ||||

| Specify input | Unit | Quantity | Costs per Unit (USD) | Total costs per input (USD) | % of costs borne by land users |

| Labour | |||||

| Repair of hydro ram pump | 1 | 2.0 | 3.75 | 7.5 | 100.0 |

| Desiltation of plastic tanks | 1 | 2.0 | 7.5 | 15.0 | 100.0 |

| Desiltation of drip irrigation system | 1 | 1.0 | 37.0 | 37.0 | 100.0 |

| Repair & maintenance of drip irrigation system | 1 | 0.5 | 37.0 | 18.5 | 100.0 |

| Equipment | |||||

| Repair of hydro ram pump | 1 | 2.0 | 10.0 | 20.0 | 100.0 |

| Repair & maintenance of drip irrigation system | 1 | 0.5 | 100.0 | 50.0 | 100.0 |

| Plant material | |||||

| Vegetable seeds | 1 | 1.0 | 15.0 | 15.0 | 100.0 |

| Fertilizers and biocides | |||||

| Diammonium phosphate (DAP) | 1 | 2.0 | 30.0 | 60.0 | 100.0 |

| Compost (250 kg) | 1 | 1.0 | 22.0 | 22.0 | 100.0 |

| Total costs for maintenance of the Technology | 245.0 | ||||

| Total costs for maintenance of the Technology in USD | 245.0 | ||||

The fruit production has not yet started as it is a newly established farming site. However, seasonal vegetable farming has just started. The produce is small as the soil nutrition building is still in process. Currently, the grown vegetables are being sold or used in the village at household level.

Quantity before SLM: None

Quantity after SLM: 2.5 acres/1ha

Production area increased as uncultivated land has been brought under cultivation.

Quantity before SLM: 0

Quantity after SLM: 14,688 litres per day

Irrigation water availability increased with innovative technological packages to previously barren land

Automized irrigation has decreased labour

Women have been allocated 10 acre arable land (pilot area) for their agricultural area. Out of this 10 acres, ICIMOD with its partners and community organization has brought 2.5 acres under cultivation.

Community institution (village development organizations) strengthened due to the approach of farming in a group.

Improved soil moisture as a result of water harvesting pits, mulching and efficient drip irrigation.

Soil cover improved due to vegetation

Reduced soil loss ( from wind and water erosion) due to application of mulch and also due to vegetation cover and above-ground biomass.

The intervention has introduced block orchard technology which will help to reduce the impacts of CO2 emmissions from vehicles along the China Pakistan Economic Corridor. Moreover, the water management interventions being used are also climate smart.