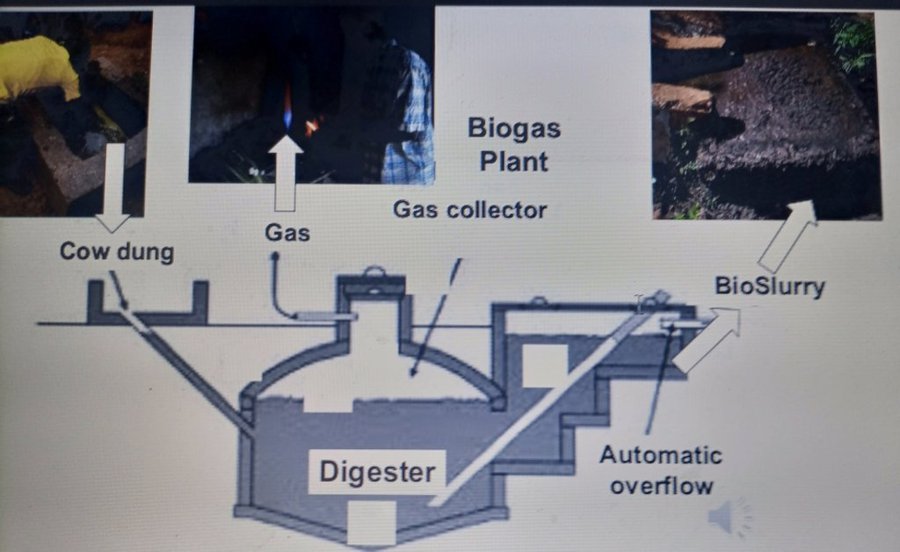

Bioslurry is a byproduct of the anaerobic process used for production of methane (biogas). It is derived from the manure and other organic materials used to feed the biodigester – which is central to a biogas plant. The biodigester is fed with thoroughly mixed livestock manure and water. For instance, a biodigester with a capacity of 8m3 requires manure from 8 cattle mixed with 20 litres of water daily. This allows consistent production of biogas, and bioslurry as a byproduct.

Bioslurry is used as an organic soil amendment that serves as an alternative to chemical fertilizers. It can also play a pesticidal role. Increasing the use of organic fertilizer can reduce the money spent on inorganic fertilizer by at least half. It also improves soil structure via the addition of organic matter. Essentially, the organic matter content of bioslurry is about 20-30%. Appropriate application of the bioslurry as organic fertilizer leads to more moisture retention in the root zone and improves crop resilience to adverse conditions. Usually, bioslurry is applied around homesteads where the biogas plant is sited where it produces energy and light for the household. The main functions of bioslurry are improving soil fertility, increasing crop production, and deterring invasion by various insects. Applying filtered liquid bioslurry to the crop supplies available liquid nutrients and manages crop infestation such as by fall armyworms and maize stalk borer.

Bioslurry is a replacement for chemical fertilizers. It is applied in two forms: liquid and dry forms. The liquid form is mainly used around the homestead, using a watering can or bucket. The dried form can more easily be carried to fields for application. Bioslurry as organic fertilizer is applied to vegetables and other perennial crops around the homestead, once during the growing season. The overall application rate by smallholders is not necessarily based on the recommendation rate per hectare but on the availability of the by-product. Row application is the efficient and effective use of resources in short supply. The rate of application to the specific parcel is on a decremental basis. The end users are pleased by its merit of increasing production, reducing investment costs on chemical fertilizers, improving soil structure and associated properties. They also like the way it makes constructive use of a byproduct that needs to be disposed of. Nevertheless, bioslurry is only available to those who invest in costly biogas plants which also require intensive labour input to collect cattle manure and fetch water.

Location: Adale-Bise Kebele, Mattu district, Oromia, Ethiopia

No. of Technology sites analysed: single site

Spread of the Technology: applied at specific points/ concentrated on a small area

In a permanently protected area?: No

Date of implementation: 2020

Type of introduction

| Specify input | Unit | Quantity | Costs per Unit (ETB) | Total costs per input (ETB) | % of costs borne by land users |

| Labour | |||||

| Labor | PDs | 10.0 | 200.0 | 2000.0 | 100.0 |

| Technician | Lump sum | 1.0 | 10000.0 | 10000.0 | |

| Equipment | |||||

| PBC, Gate valve, plastic pipes, stove, bulbs | Lump sum | 1.0 | 6000.0 | 6000.0 | |

| Spade | Nnumber | 1.0 | 300.0 | 300.0 | 100.0 |

| Wheel barrow | Number | 1.0 | 1600.0 | 1600.0 | |

| Construction material | |||||

| Cement | ton | 1.0 | 10000.0 | 10000.0 | |

| Stone | m3 | 2.0 | 1500.0 | 3000.0 | 100.0 |

| Sand | m3 | 8.0 | 500.0 | 4000.0 | 100.0 |

| Total costs for establishment of the Technology | 36'900.0 | ||||

| Total costs for establishment of the Technology in USD | 694.65 | ||||

| Specify input | Unit | Quantity | Costs per Unit (ETB) | Total costs per input (ETB) | % of costs borne by land users |

| Labour | |||||

| Family labor to supply feedstock and collect the product. | PDs | 365.0 | 100.0 | ||

| Equipment | |||||

| Accessories | Lump sum | 5.0 | 200.0 | 1000.0 | 50.0 |

| Total costs for maintenance of the Technology | 1'000.0 | ||||

| Total costs for maintenance of the Technology in USD | 18.83 | ||||

The farmer observed a significant increase in crop yield per unit of land post the application of bioslurry. According to the farmer, the yield increment amounts to more than double the harvest that used to be gained via the use of chemical fertilizers.

A farmer communicated the improvement in the taste of the maize grain harvested from the farmland treated with bioslurry.

It increases biomass production and feed availability from crop residues.

According to the land user, tilling the farmland treated by bioslurry is lighter than the other soil. Furthermore, it forms an aggregate that otherwise remains dusty on tillage without the use of organic fertilizer or the bioslurry.

Not yet empirically measured.

As it promotes the growth of diverse plant species, it has positive effects on reducing evoration.

As the technology is not widely adopted and measured its impact is negligible in this regard.

Reduces the runoff of soil and water because of good ground cover and high biomass production.

As it arrest the downstream runoff, it reduces the damage it may imposes on the adjacent fields.