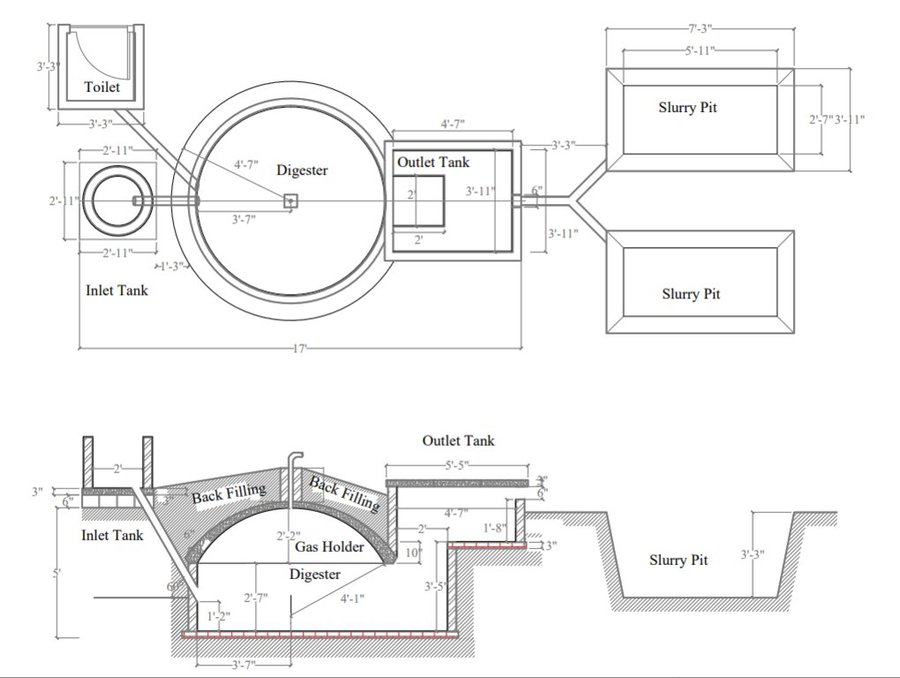

Biogas is a renewable fuel produced through the anaerobic digestion of organic matter, such as food or animal waste. Typically, biogas is intentionally generated in an enclosed environment (a biogas plant) for household consumption. This plant is constructed near a livestock shed for easy collection of animal waste and in proximity to households, mainly used for cooking, heating, and as an alternative to commercial LPG gas.

The plant can be adjusted based on the amount of animal waste, making it viable for smallholder farmers with just a few cows. In most parts of the country, the technology is modified so that even a small amount of animal waste can produce some gas. The digestion chamber is made smaller in diameter and height to generate enough pressure for the gas to reach the stove through the pipe. Initially, the Biogas project started to promote clean and renewable energy for household cooking, reducing the consumption of firewood. Currently, there are more than 8000 biogas plants of different sizes - 4 m3, 6 m3, 8 m3, and 10 m3, and a few large-scale biogas greater than 50 m3 in large individual dairy farms and government livestock farms.

The major activities and inputs required to establish and maintain the technology include having ample space around the residential area for the plant's construction. Additionally, materials such as cement, sand, gravel, stone, iron rods, pipes, pressure gauges, and a stove are necessary. Human resources are needed for the construction of the plant, and land users should have livestock (cows, buffaloes, horses, etc.) that can provide dung/waste for gas generation.

There are numerous benefits and impacts of the technology, including its positive effects on rural communities, greenhouse gas emission reduction, maintaining carbon neutrality, and minimizing the use of imported LPG gas and chemical fertilizers. It also reduces electricity bills needed for operating electric heaters, saving time for land users who would otherwise collect firewood. The by-product (bio-slurry) from the digester is used as organic fertilizer, enhancing crop productivity and serving as a nutritious feed supplement for animals.

Land users both appreciate and have concerns about the technology. They acknowledge the cost reduction benefits, citing the significant savings compared to market-priced commercial LPG gas and reduced expenses on operating electric heaters. The technology has also provided them with additional time by eliminating the need to gather firewood. The bio-slurry, a by-product of the biodigester, serves as fertilizer to enhance crop production and contributes to livestock waste management, improving livestock health and production.

However, land users note that biogas plant establishment is expensive and may not be suitable for economically disadvantaged individuals. Some users experience challenges, such as the biodigester chamber failing to produce enough gas despite being constructed according to technical specifications. The daily requirement of adding animal waste to the input tank is perceived as tedious, and for land users with only one or two milking cows, supplying the required amount of animal waste for the biodigester chamber is often a problem.

Location: Darchung under Shumar Chiwog (Community), Shumar Gewog (Block), Pemagatshel Dzongkhag (District), Bhutan

No. of Technology sites analysed: single site

Spread of the Technology: applied at specific points/ concentrated on a small area

In a permanently protected area?: No

Date of implementation: 2021

Type of introduction

| Species | Count |

| cattle - dairy | 8 |

| Specify input | Unit | Quantity | Costs per Unit (Bhutanese Ngultrum) | Total costs per input (Bhutanese Ngultrum) | % of costs borne by land users |

| Labour | |||||

| Labour | person-days | 18.0 | 350.0 | 6300.0 | |

| Masion | person-days | 12.0 | 1000.0 | 12000.0 | |

| Equipment | |||||

| Mixture machine | no | 1.0 | 1740.0 | 1740.0 | |

| GI nozzle | no | 1.0 | 113.0 | 113.0 | |

| Plant material | |||||

| water draining pipe | no | 1.0 | 262.0 | 262.0 | |

| Main gas valve | no | 1.0 | 523.0 | 523.0 | |

| Paint brush | no | 1.0 | 85.0 | 85.0 | |

| Iron brush | no | 1.0 | 85.0 | 85.0 | |

| CPVC glue (50gm) | Jar | 1.0 | 390.0 | 390.0 | |

| Teflon tape | roll | 1.0 | 25.0 | 25.0 | |

| PVC pipe 4"10' (inlet) | no | 1.0 | 1050.0 | 1050.0 | |

| Construction material | |||||

| Cement | Bag | 18.0 | 380.0 | 6840.0 | |

| Bricks | No | 1000.0 | 11.0 | 11000.0 | |

| Gravels | Truckload | 0.5 | 5000.0 | 2500.0 | |

| Sand | Truckload | 0.25 | 6000.0 | 1500.0 | |

| Arcrylic paint | litres | 3.0 | 350.0 | 1050.0 | |

| Iron rod | kg | 10.0 | 70.0 | 700.0 | |

| Dome pipe | No | 1.0 | 1170.0 | 1170.0 | |

| Other | |||||

| Stove | No | 1.0 | 1399.0 | 1399.0 | |

| CPVC Pipe (10') | No | 10.0 | 350.0 | 3500.0 | |

| Gas tap | No | 1.0 | 465.0 | 465.0 | |

| Pressure meter | No | 1.0 | 320.0 | 320.0 | |

| Elbow joint | No | 4.0 | 350.0 | 1400.0 | |

| T - union | No | 2.0 | 150.0 | 300.0 | |

| Total costs for establishment of the Technology | 54'717.0 | ||||

| Total costs for establishment of the Technology in USD | 661.39 | ||||

The hospital is located 10 km away from Land users' places. Which makes it a little difficult during emergencies. The school is 2 Km away which is very near. There are also Gypsum Mining which provides off-farm activities to many land user in the locality. The land user is trained in making Biogas plants, this also provides him the opportunity to work off-farm. When it comes to energy, apart from energy to light the house, energy is required for cooking purposes. This energy was previously derived from LPG, however, after the Biogas plant land user is not having any difficulties with energy shortage. Land users have their own water source and the same water is used to feed Jersey cows. Land users also said that they get financial assistance from Bhutan Development Bank Limited.

Land users didn't keep a record of the production, however, it was reported that crop production has improved.

land users reported that crops are healthier and green when manure prepared from cow dung/ biogas plants is applied on the land.

Land user is also members of milk cooperatives. He maintains different fodder species to have feed for his cows throughout the years. He said fodder production has increased over the years.

Different species of fodder species like Napier, Ruzi, Guatemala, Super Napier, Banana, Rice straw, maize, and fooder tree species like Ficus auriculata, Ficus simicordata, etc., were observed.

Quantity before SLM: 6 LPG cylinder per annum

Quantity after SLM: 0

Each LPG cost around Nu. 1000. LPG is completely replaced by biogas technology.

Water was not a problem from the beginning. However, with an improved breed of cow (jersey), water sanitation is also given more importance. Because water can bring diseases to family members and livestock.

Land user don't have to buy LPG cylinders. He saves around 7000 in a year.

Workload has increased since the biogas plant was constructed. Every day the land user have to collect cow dung and add it to the plant. He also has to collect slurry and add to the land to improve fertility.

Scope to conduct research to estimate GHG emission reduction from biogas technology