No-till with controlled traffic [Australia]

- Creation:

- Update:

- Compiler: Des McGarry

- Editor: –

- Reviewer: Alexandra Gavilano

no-till, permanent uncropped wheel tracks,eliminate soil compaction, judiciois spraying

technologies_945 - Australia

View sections

Expand all Collapse all1. General information

1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

01/02/2004

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Large-scale no-till grain production with permanent wheel tracks

common to all on-farm equipment.

2.2 Detailed description of the Technology

Description:

This controlled traffic, no-till farming system (CT/NT) is practiced on a 1,900 ha farm on the broad, almost flat Jandowae Plains in semi-arid Queensland, Australia. Principal soil types are vertisols, with some poorer areas where the sand content is greater, and these have a tendency to hard-set and crust. Over the past five years, the farm owner has changed the farming system completely from conventional farming to no-till with controlled traffic. Controlled traffic means permanent uncropped wheel tracks or ‘tramlines’: all equipment has 2 metre axles. The total farm machinery comprises a tractor, a spray rig and two 11 meter zero-till planter/fertilizer units; one each for wheat and sorghum sowing. The tramlines were laid out two years ago by a contractor using Geographical Positioning System (GPS).

The main technical objective was to eliminate soil compaction. The CT/NT combination ensures the land -between the tramlines - remains in excellent condition. There has been no ploughing or tillage at all in those 5 years. He practices a three year rotation between winter wheat, summer sorghum and fallow, but the system is not fixed: it depends very much on soil moisture status and thus on the rainfall (opportunity cropping). Generally in summer about one third is in summer sorghum and in winter about one third in winter wheat, the rest of the land is

under fallow. The one-year fallow is maintained through the use of herbicides sprayed onto the undisturbed residue from the previous crop. The system is designed for rain capture - to build up soil moisture stores in the fallow periods for subsequent crops - and for disease control (to ‘spell’ the land). During the cropping cycle, the key to his effective weed control system is ‘to get in early’ and ‘actively chase weeds’ through judicious spraying. The farm is now free of the locally common persistent weed Erigeron annuus. In the five years his sorghum yields have risen from 3 to 7 tons per hectares. Over the last three years the soil has improved, becoming soft, friable and moist between his plant lines. Infiltration has improved a lot and soil structure is now excellent.

Tractor use and overall fuel consumption has decreased to less than one quarter of that under conventional tillage. Correspondingly the workload is hugely reduced: from four men required under the conventional system for an equivalent area, the farmer is the sole operator, very occasionally assisted by his son, and a paid contractor for harvesting. He is so satisfied with the CT/NT system that he is attempting to purchase a nearby property to extend the area that he can farm using his current machinery.

2.3 Photos of the Technology

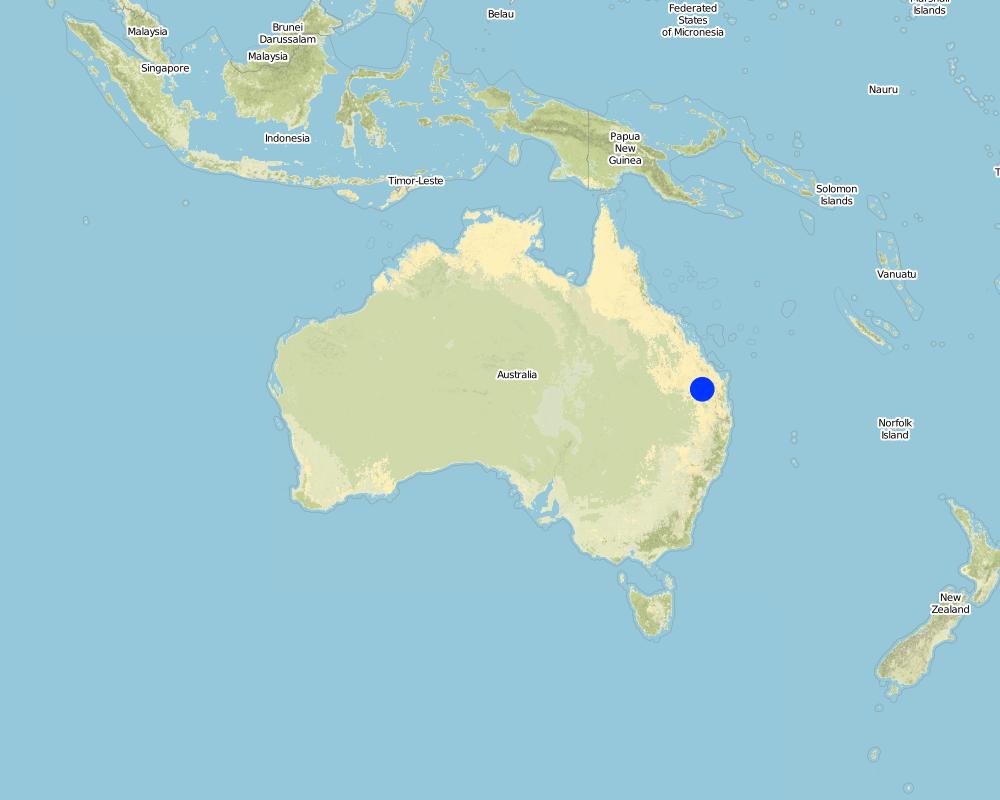

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Australia

Region/ State/ Province:

Jimbour (north of Dalby), Queensland

Map

×2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

3. Classification of the SLM Technology

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Comments:

Major land use problems (compiler’s opinion): The farmer’s main reason for starting the combination of CT and NT was to rid himself of soil compaction, in order to achieve better utilisation of locally low and unpredictable rainfall amounts while minimising costs and reducing labour and machinery requirements.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- rainfed

Number of growing seasons per year:

- 2

Specify:

Longest growing period in days: 180

Longest growing period from month to month: Oct - Apr

Second longest growing period in days: 180

Second longest growing period from month to month: Apr - Sep

3.5 Spread of the Technology

Comments:

Total area covered by the SLM Technology is 19 m2.

3.6 SLM measures comprising the Technology

3.7 Main types of land degradation addressed by the Technology

soil erosion by wind

- Et: loss of topsoil

physical soil deterioration

- Pc: compaction

soil erosion by water

- Wg: gully erosion/ gullying

- Wt: loss of topsoil/ surface erosion

Comments:

Main type of degradation addressed: Wt: loss of topsoil / surface erosion, Pc: compaction

Secondary types of degradation addressed: Wg: gully erosion / gullying, Et: loss of topsoil

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

Comments:

Main goals: mitigation / reduction of land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.2 Technical specifications/ explanations of technical drawing

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: moderate

Main technical functions: control of raindrop splash, control of dispersed runoff: retain / trap, improvement of ground cover, increase in organic matter, increase of infiltration, increase / maintain water stored in soil, improvement of soil structure, reduction of compaction by traffic, increase of soil fertility

Agronomic measure: conservation tillage

Remarks: with controlled traffic

4.3 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Aus$

4.5 Costs and inputs needed for establishment

Comments:

Duration of establishment phase: 12 month(s)

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

Comments:

Machinery/ tools: tactor,spray rig, zero-till planter/fertilizer, iron rod

Comparison of costs between conventional tillage and no-till farming (CT/NT): (1) Labour costs are 4x less in CT/NT: 4 men used to work on the farm (conventional), now the farmer is alone – (plus contractors for harvesting). (2) Average annual diesel consumption: reduced from 108,333 litres (conventional) to 13,636 litres (no-till) which is 8 times less. (3) Costs of equipment to set up a CT/NT system (US$ 240,000) are 3 times less than that for conventional tillage equipment (US$ 700,000).

(4) For biocides he has to invest 5 times more in CT/NT. The conventional values are estimates.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

In average one third of the farm area is in crop and two thirds are fallow. This means that overall farming costs per

ha are reduced, since during fallow period activities are limited to spraying herbicides. Labour costs approximately US$ 160 per day. Machinery costs average out at US$ 20 per hour (diesel costs US$ 0.9 per litre). All the data comes from this single farmer. Purchase of equipment is not included in the table above.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- arid

- semi-arid

Thermal climate class: subtropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- fine/ heavy (clay)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- commercial/ market

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

Indicate other relevant characteristics of the land users:

and own 88% of the land.

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Income and costs

farm income

Socio-cultural impacts

conflict mitigation

Ecological impacts

Water cycle/ runoff

excess water drainage

Soil

soil moisture

soil cover

soil loss

soil compaction

soil organic matter/ below ground C

6.2 Off-site impacts the Technology has shown

reliable and stable stream flows in dry season

downstream flooding

downstream siltation

groundwater/ river pollution

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

Comments:

200 land user families have adopted the Technology without any external material support

There is no trend towards spontaneous adoption of the Technology

Comments on adoption trend: There isn’t a strong trend now towards growing spontaneous adoption: uptake has slowed dramatically as many conservative farmers prefer to continue their traditional tillage practices.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Land that previously was un-farmable is now under crops. Site inspection shows initially poor land to be now in good condition (after only 5 years). The value of the land has increased How can they be sustained / enhanced? Farmers practising CT/NT can and are buying/leasing more land, which will improve the overall state of the land in Queensland. |

|

Farmers can manage much larger growing areas with less personnel and equipment. A single operator is well able to run a large arable farm on his own How can they be sustained / enhanced? Ditto. |

|

Cereal farming is now less prone to yield losses (and crop failure) in drought years – as there is better rainwater infiltration and water use efficiency with CT/NT How can they be sustained / enhanced? Continue with the system. |

| He has all weeds under control (without need for tillage). |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The contract harvester runs on 3 m wide axles, so the wheels run on the beds. However, there has only been one wet harvest in 5 years so the incidence of soil compaction from harvesting is negligible | This is not really seen as a problem. One solution would be to build a dedicated harvester (too expensive) or find a contractor with equipment that fitted the system. |

| A conservative mentality towards conservation agriculture is constraining the adoption of the system by other farmers | Continue demonstrating and disseminating knowledge about benefits. |

7. References and links

7.2 References to available publications

Title, author, year, ISBN:

Blackwell P (1998) Customised controlled traffic farming systems, instead of standard recommendations or ‘tramlines ain’t tramlines’.In Second national controlled farming conference, pp. 23–26. Eds JN Tullberg and DF Yule.

Available from where? Costs?

Gatton College: University of Queensland

Title, author, year, ISBN:

Hulme PJ, McKenzie DC, MacLeod DA and Anthony DTW (1996) An evaluation of controlled traffic with reduced tillage for irrigated cotton on a Vertisol.

Soil and Tillage Research 38:217–237

Title, author, year, ISBN:

McGarry D, Bridge BJ and Radford BJ (2000). Contrasting soil physical properties after zero and traditional tillage of an alluvial soil in the semi-arid tropics. Soil and Tillage Research 53:105–115

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules