Production and use of rice husk biochar in rice seed beds and vegetable production. [Cambodia]

- Creation:

- Update:

- Compiler: Stefan Graf

- Editor: –

- Reviewers: Alexandra Gavilano, Deborah Niggli

ការផលិត នឹងប្រើប្រាស់ជីធ្យូងអង្កាមលើថ្នាលសំណាបនឹងដំណំាបន្លែ (Khmer)

technologies_1229 - Cambodia

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Khun Lean Hak

SOFDEC/LAREC, www.sofdec.org

Cambodia

SLM specialist:

Pith Khonhel

LAREC

Cambodia

SLM specialist:

Bin Sreytouch

SOFDEC

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Society for Community Development in Cambodia (SOFDEC) - CambodiaName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Local Agricultural Research and Extension Centre (LAREC) - Cambodia1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Rice husks as well as empty seeds are pyrolised and used as a soil amendment in the rice seed beds and the vegetable gardens.

2.2 Detailed description of the Technology

Description:

Biochar is the residue left after the pyrolysis of any organic matter and is used as a soil amendment. Pyrolysis occurs when the organic matter is heated in anaerobic conditions, which is usually done in specially designed kilns. Sometimes it is also made in a conventional fire, which is extinguished before the char turns to ash. Agricultural wastes like rice husks or unfilled grains are mainly used. Biochar can have many positive effects on the soil and plants:

-It buffers the pH, and has usually a high pH due to theash content.

-Due to its porous structure, it holds water and serves as refuge for microorganisms.

-It absorbs and adsorbs nutrients, both cations and anions. They are available for the plant roots.

-It can increase the resistance of plants to diseases.

Due to all these effects, the increased yields are higher than those that can be achieved only through the nutrients contained in the Biochar itself. Biochar is and was used in many parts of the world as soil amendment, with some benefits persisting for centuries. In Cambodia it was used during the Pol Pot regime to reduce the smell of the human faeces that were used on the fields due to a lack of other fertilizers. Today research in the Biochar domain is increasing, especially since the discovery of the man-made terra preta soils in South America.

Biochar is mainly used to increase the fertility, water holding capacity and carbon content of the soil. The fact that the benefits of Biochar addition to the soil remain for several years, unlike chemical fertilizers, makes it attractive to farmers. Other purposes, like the increased resistance of plants to diseases and buffering of nutrients are also of importance.

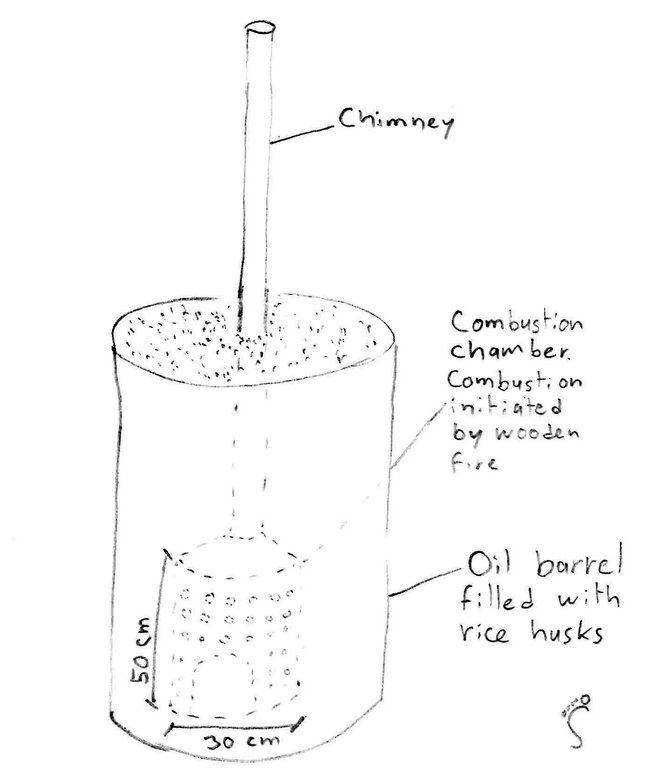

Biochar was introduced or reintroduced trough different NGOs, JICA (Japanese International Cooperation Agency) in this case study. Because of knowledge exchange between farmers, a rice husk char/ash mix, as residue from the pottery baking, was used already in 2011. In 2013 JICA borrowed a Biochar kiln to the local farmer self-help group with a training, so they could produce Biochar by themselves. The inner part of the kiln (cf. technical drawing) is filled with wood and lit. It is then put into an empty oil barrel, which is filled with rice husks. The heat pyrolyses the husks from the bottom to the top of the barrel, and the gases are burned in the inner part of the kiln and the chimney. Just before the upper part is pyrolysed, the husks are extinguished. There is a weight loss of about 50 to 60 % caused by this process. The Biochar is added to the fields after ploughing, and the fields are harrowed. In this case study, Biochar is used both in rice seed beds and in a vegetable patch. Concentrations of 0.5 kg/m2 are used in the rice seed bed, and 2.5 kg for the vegetables. Due to the little available quantities of husks, Biochar is not applied to the field yet. The use of Biochar is spreading quickly from farm to farm

The analysed area is flat (slope < 2%), with a tropical climate (dry season from November to May and wet season from June to October), and the soils are mostly sandy or loamy. The soil has a low fertility, contains little organic matter, and acidifies. The area has been deforested a long time ago, and the groundwater table is rather high (1-2 m during the dry season, on the surface during wet season).

Due to climate change, farmers notice more erratic rainfall, temperature rises and more recurrent droughts. Rice is the predominant crop grown in the area, since it serves as staple food (mix subsistence and commercial activities). Cattle are usually grazing on the fields after the harvest, without much control. Thus the cattle grazes too often and too much on the same spot, leading to degradation.

The increasing migration rate (the young generation leaves the villages to work in the cities, garment industry or abroad) results in a decrease of available labour force in the area which has detrimental effects on the agricultural activities. Furthermore, the civil war in the 1970s (Khmer Rouge) led to the loss of agricultural knowledge. Several NGOs are trying to re-establish the knowledge.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Cambodia

Region/ State/ Province:

Kampong Chhnang

Further specification of location:

Kraing Leav

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- 0.1-1 km2

Comments:

Area unknown and rapidly spreading.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

It was introduced in 2010 by JICA, the Japanese International Cooperation Agency.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Annual cropping - Specify crops:

- vegetables - other

- vegetables - leafy vegetables (salads, cabbage, spinach, other)

- vegetables - root vegetables (carrots, onions, beet, other)

- vegetables - melon, pumpkin, squash or gourd

- rice, cucumber

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 210, Longest growing period from month to month: June-December

Comments:

Major land use problems (compiler’s opinion): Soil fertility decline, water availability

Major land use problems (land users’ perception): Water availability. Interestingly the farmer says that soil fertility is not a problem, as the farmers know about the use of compost. The compost application is the problem.

Livestock is grazing on crop residues

In the vegetable patch the farmer plants cucumber, pumpkin, onion, watermelon and leaf vegetables in the early wet season, before planting rice.

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

3.5 SLM group to which the Technology belongs

- integrated soil fertility management

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

- Ca: acidification

water degradation

- Ha: aridification

Comments:

Main causes of degradation: soil management (Ploughing and bare soil during dry season.), labour availability (Farmers go to work in the garment industry, in construction, or sell their labor elsewhere.)

Secondary causes of degradation: deforestation / removal of natural vegetation (incl. forest fires) (Deforestation happened many years ago.), overgrazing (Uncontrolled grazing during dry season.), change in temperature (More hot days according to UNDP and farmers.)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Biochar kiln. In the inner part, the combustion chamber, a wooden fire is lit. The burning chamber is then placed in the oil barrel, which is filled with rice husks. The heat pyrolyses the husks, the gas burn in the chamber and chimney. When pyrolysis is almost completed, the char is extinguished.

Kampong Chhnang

Date: 2014

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: moderate (When farmers only buy Biochar the required technical knowledge is low.)

Main technical functions: increase in organic matter, increase in nutrient availability (supply, recycling,…)

Secondary technical functions: improvement of surface structure (crusting, sealing), improvement of topsoil structure (compaction)

Manure / compost / residues

Material/ species: Rice husk Biochar (together with compost, which he already did before)

Quantity/ density: 0.5-2.5

Remarks: Entity: kg/m^2. Distributing on fields and harrowing.

Author:

Stefan Graf, Switzerland

4.2 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Riels

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

4000.0

Indicate average wage cost of hired labour per day:

5.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | biochar kiln |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | kiln | 1.0 | 50.0 | 50.0 | ||

| Total costs for establishment of the Technology | 50.0 | |||||

| Total costs for establishment of the Technology in USD | 0.01 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Biochar making | Whenever there is time |

| 2. | Adding Biochar to the fields after the compost was plowed in, and harrowing. | Yearly, before planting. |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labour | 1.0 | 20.0 | 20.0 | 100.0 | |

| Equipment | machine use | 1.0 | 0.25 | 0.25 | 100.0 | |

| Plant material | rise husks | 1.0 | 4.0 | 4.0 | 100.0 | |

| Total costs for maintenance of the Technology | 24.25 | |||||

| Total costs for maintenance of the Technology in USD | 0.01 | |||||

Comments:

The costs are indicated per unit; a unit is one biochar kiln used on 1 a. The costs were calculated in 2014 for the vegetable beds, where the farmer uses around 2.5 kg/m2. He also uses Biochar on the rice seedling bed, with concentrations of around 0.5 kg/m2, 5 times less than in the vegetable patch. In the vegetable patch the farmer plants cucumber, pumpkin, onion, watermelon and leaf vegetables in the early wet season, before planting rice.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The factors affecting the cost the most are the biochar kiln, and the amount of added Biochar.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

1486.45 mm 2013 in Kampong Chhnang

Agro-climatic zone

- sub-humid

Thermal climate class: tropics. 27° to 35°C

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

5.4 Water availability and quality

Ground water table:

< 5 m

Water quality (untreated):

poor drinking water (treatment required)

5.5 Biodiversity

Species diversity:

- low

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

- average

Individuals or groups:

- individual/ household

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Population density: 10-50 persons/km2

Annual population growth: 0.5% - 1%

Off-farm income specification: handicraft, remittances and factory work

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

- individual, not titled

Land use rights:

- communal (organized)

- individual

Water use rights:

- open access (unorganized)

Comments:

Land users have a title that is not recognized by the state.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

According to the farmer, 50 to 70 % yield increase on his vegetable patches.

Income and costs

expenses on agricultural inputs

Comments/ specify:

Rice husks become a demanded product instead of a waste. On the other hand, less pesticides are needed.

workload

Comments/ specify:

Biochar has to be made and added to the fields.

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Increased production, healthier plants/less pests.

health situation

Comments/ specify:

Less pesticides needed.

contribution to human well-being

Comments/ specify:

Increased income, less expenses on pesticides.

Ecological impacts

Soil

soil moisture

Comments/ specify:

Plants can stand a short dry spell better if grown with Biochar.

nutrient cycling/ recharge

Comments/ specify:

A waste, rice husks, is returned to the soil. Biochar also adsorbs and absorbs nutrients.

soil organic matter/ below ground C

Comments/ specify:

The carbon from Biochar has a long half-life period in the soil .

Biodiversity: vegetation, animals

pest/ disease control

Comments/ specify:

Less pesticides needed.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not known |

| local windstorm | not known |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Comments:

The costs for the pyrolysis kiln were not borne by the land user. But as the farmer of this case study wants to build an own kiln as soon as the NGO needs it again, it is positive.

6.5 Adoption of the Technology

Comments:

100% of land user families have adopted the Technology with external material support

100 land user families have adopted the Technology with external material support

Considering only the farmers applying the technology with this stove. Other farmers buy Biochar, or burn the rice husks and extinguish them. But those farmers are nearly impossible to quantify as it changes quickly. The support was the kiln, which is only a small part of the costs.

Considering only the farmers applying the technology with this stove. Other farmers buy Biochar, or burn the rice husks and extinguish them. But those farmers are nearly impossible to quantify as it changes quickly.

In another area of Cambodia where the Ministry of Agriculture, Forestry and Fisheries (MAFF) is doing Biochar research, there was such a strong adoption of Biochar use that there are no more control areas. In Kampong Chhnang, the use of Biochar starts to spread now.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Less insect damages where Biochar is applied. |

| Good growth of vegetables, with increased yields especially for onions. |

| The rice seedlings are stronger, and the roots break less while transplanting, and the plants recover quickly. |

| The plants survive a short dry spell better. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Soil amendment with long-term effect, as Biochar has a long half-life period. |

| Buffering and raising of the pH, especially in sandy soils. |

| Less washing out of nutrients. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Substrate to make Biochar (rice husks) is difficult to find in the area in big amounts, as only small rice mills are working there. |

Rice husks are wasted in other places. Networking with other villages. Use other (waste) sources of organic matter like leaves. |

| Increased workload for the Biochar production (compensated by the increased yields). | Use a bigger kiln to decrease the workload. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The energy produced during the pyrolysis is wasted. | Use it to power engines or as heating source. This would only be viable on large-scale kilns. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

14/08/2014

7.2 References to available publications

Title, author, year, ISBN:

Ithaka Journal

Available from where? Costs?

www.ithaka-institut.org

Title, author, year, ISBN:

Biochar foundation

Available from where? Costs?

www.britishbiocharfoundation.org

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules