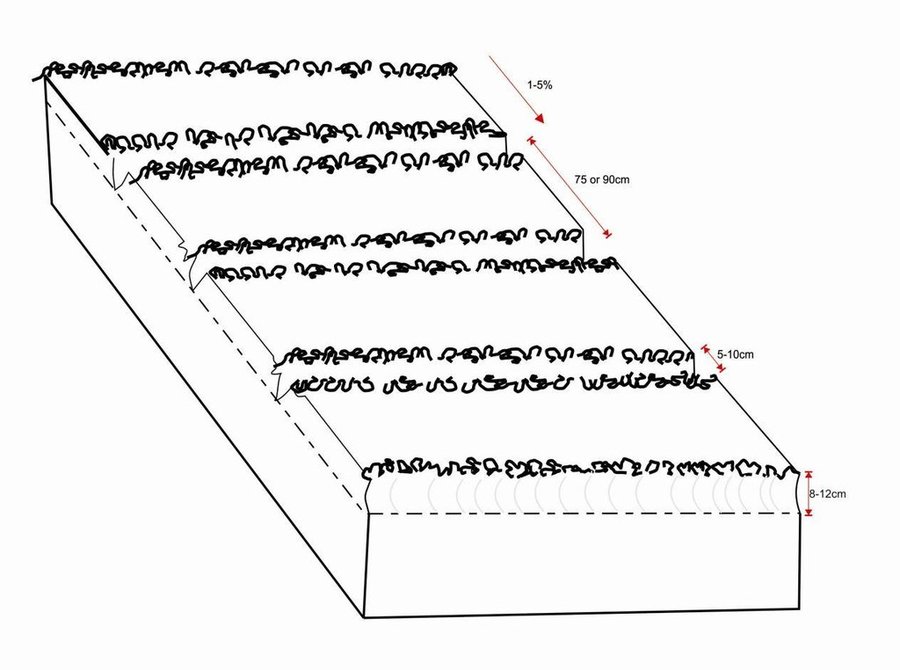

Zero-tillage takes advantage of the beneficial effects of biological processes to loosen the soil and to improve fertility. The organic matter from these processes aggregate the soil while the movement of soil organisms like worms and termites loosen the soil. This is called biological tillage and replaces mechanical tillage. The untilled soil surface covered by residues will require a planter specialized to plant in these conditions. In a sense, adopting zero-till does actually require a zero-till planter. The development of the strip-planter has made zero-till a viable option for animal draft farmers, which until now was not possible due to the unavailability or high cost of zero-till planters. The new planter is both cheap and easy to manufacture locally. The planter uses a narrow tine to open a planting furrow and seed/fertilizer is metered by vertically rotating plates. The planter is pulled by oxen and can plant rows of 75cm or 90cm rows with an intra-row which is determined by the seed plate used (3, 4, 5,…… seeds/m). The planting technology needs to be complemented with sound residue cover and weeding management practices.

Purpose of the Technology: The planter enables planting and fertilizing in untilled soil so that the soil residue cover and soil structure are preserved and can be used sustainably. The protective soil cover reduces evaporation and enhances infiltration while the improved soil structure and organic matter content increases soil water storage making zero tillage an important drought mitigating strategy. The immediate benefits of adopting zero-till are the possibility to plant a bigger area quickly and in time as well as the reduced soil erosion.

Establishment / maintenance activities and inputs: The first step in establishing zero-till is to assess the soil condition and levels of degradation. Where possible tests should be carried out but where not, the farmer needs to start on a small plot to check if there will be yield reduction from not tilling the soil. Where soils are severely degraded, an establishment phase should be embarked on where reduced tillage is practiced until the soil structure has recovered sufficiently to support crop growth without tillage. Liming acidic soils followed by a final ploughing will be required in the first year to correct the soil pH which otherwise will be difficult to correct once conservation tillage has been established. The organic matter levels need to be increased by increasing the amount of residues produced by the crop (i.e. the yields) and retaining these as soil cover. The next establishment activity is the purchase of the planter unit. Maintenance activities include planting and fertilizing in the same operation and weeding. Weeding will have to involve herbicide use to handle increased weed densities implying that spraying will become a major operation. In addition to the normal conventional inputs, herbicides will also become a major input and cost.

Natural / human environment: Zero-till has been applied in a wide range of bio-physical environments but mostly by the large scale farmers. The unavailability and high cost of specialized zero-till planter for small-scale farming has resulted in low adoption rates. The development of the Magoye Planter creates new opportunities for this practice. The farmer has to have sufficient knowledge to assess the soil condition and decide if is too degraded for zero-till or how long the transitional phase should be. Literacy is essential as the farmers will have to learn new approaches on weed control, pest control and crop rotations and adapt practices to suit his/her specific conditions.

Lugar: Mazabuka/Magoye, Zambia/Southern Province, Zambia

No. de sitios de Tecnología analizados:

Difusión de la Tecnología:

¿En un área de protección permanente?:

Fecha de la implementación: hace menos de 10 años (recientemente)

Tipo de introducción

| Especifique insumo | Unidad | Cantidad | Costos por unidad (Kwacha) | Costos totales por insumo (Kwacha) | % de los costos cubiertos por los usuarios de las tierras |

| Equipo | |||||

| Magoye Planter | piece | 1,0 | 500,0 | 500,0 | 100,0 |

| Knapsack sprayer | piece | 1,0 | 80,0 | 80,0 | 100,0 |

| Costos totales para establecer la Tecnología | 580.0 | ||||

| Costos totales para establecer la Tecnología en USD | 116.0 | ||||

| Especifique insumo | Unidad | Cantidad | Costos por unidad (Kwacha) | Costos totales por insumo (Kwacha) | % de los costos cubiertos por los usuarios de las tierras |

| Mano de obra | |||||

| Slashing, spreading residues | person days | 8,0 | 2,5 | 20,0 | 100,0 |

| Liming | person days | 2,0 | 2,5 | 5,0 | 100,0 |

| Chemical weeding | person days | 24,0 | 1,0 | 24,0 | 100,0 |

| Harvesting | person days | 8,0 | 2,5 | 20,0 | 100,0 |

| Equipo | |||||

| Animal traction for planting and fertilizing | ha | 1,0 | 40,0 | 40,0 | 100,0 |

| Material para plantas | |||||

| Seeds | kg | 20,0 | 2,5 | 50,0 | 100,0 |

| Fertilizer | kg | 400,0 | 0,8 | 320,0 | 100,0 |

| Herbicides | l | 5,0 | 6,0 | 30,0 | 100,0 |

| Lime | ton | 1,0 | 42,0 | 42,0 | 100,0 |

| Indique los costos totales para mantenecer la Tecnología | 551.0 | ||||

| Costos totales para mantener la Tecnología en USD | 110.2 | ||||

Cantidad antes de MST: 2-3ha

Cantidad luego de MST: >10