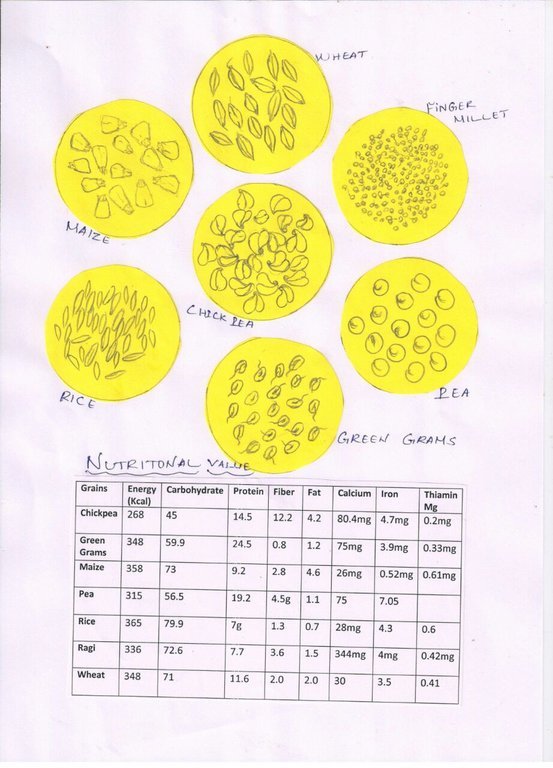

The multigrain flour can be used to produce both "nutritional balls" and "energy drinks". The multi-grain flour is composed of 7 grains, namely raw rice, wheat, finger millet (raggie), green grams, maize, chick pea (channa) and pea. These grains are rich in vitamins and minerals.

Preparation: Equal quantities of the grains of wheat, finger millet (raggie), green grams, maize, channa and pea are soaked seperately in water for 24 hours. After being soaked well, they are tied in a soft wet cotton cloth for 1 or 2 days until sprouts come out of the grain. Once the sprout is out, the grains are dried in the sun and afterwards fried separately one by one. After being fried, the husk is removed from channa, pea and green grams. Finally all grains together are grounded in a grinding mill. Once the flour is ready, as part of the value addition process, ghee and smashed jaggery (unrefined brown sugar made from sugar cane or palm tree) are added and mixed thoroughly. If needed, 100 grams of raisins and cashew nuts can be added to the products for garnishing. After mixing them well, the powder can either be kept as it is or shaped like balls.

The process of dry roasting keeps the nutritional value intact and leads to a longer shelf life. The rich content of vitamins, minerals and carbohydrates makes the nutritional balls particularly valuable for children, adolecent and pregnant women, preventing malnutrition. They are as well suitable for people suffering from diabetics, if consumed without sugar.

The prime objective of the Technology is eliminating anemia among the rural poor, especially among women and children and make them self sufficient. It can also be an additional source of income, once people become aware of the high nutrient level and begin buying the product.

The nutritional ball, locally named "Horlicks laddoo", has a particularly high nutritional value and is promoted to the rural communites in the target villages of the NGO "Nirmal Mahila Kalyan Kendre" (NMKK), especially for women and children. It is also used as an energy drink, especially for children, preventing malnutrition.

Lieu: Town - Darbhanga, BIHAR, Inde

Nbr de sites de la Technologie analysés: 10-100 sites

Diffusion de la Technologie: répartie uniformément sur une zone (approx. 10-100 km2)

Dans des zones protégées en permanence ?:

Date de mise en oeuvre: 2003

Type d'introduction

| Spécifiez les intrants | Unité | Quantité | Coûts par unité (Rupees) | Coût total par intrant (Rupees) | % des coût supporté par les exploitants des terres |

| Main d'œuvre | |||||

| Grinding Charge | 1Kg | 8,0 | 5,0 | 40,0 | 100,0 |

| Equipements | |||||

| Vessels | 8 | 8,0 | 120,0 | 960,0 | 100,0 |

| Cotton Cloth | 7Pcs | 4,0 | 148,0 | 592,0 | 100,0 |

| Tharpolin | 1Pc | 1,0 | 1500,0 | 1500,0 | 100,0 |

| Matériel végétal | |||||

| Pulses (Chick Pea,Pea,Green grams) | 3Kg | 3,0 | 120,0 | 360,0 | 100,0 |

| Grains (Wheat,Maize, Ragi,Rice) | 4Kg | 3,0 | 30,0 | 90,0 | 100,0 |

| Packing Polythin | 1Kg | 1,0 | 200,0 | 200,0 | 100,0 |

| Coût total de mise en place de la Technologie | 3'742.0 | ||||

| Coût total de mise en place de la Technologie en dollars américains (USD) | 55.85 | ||||