Mechanized Raised Beds (MRB)-technology has been applied by the International Centre of Agriculture Research in Dryland Areas (ICARDA) and national partners in Egypt. Egypt is a water scarce country and 95% of its water comes from beyond its borders. In addition, Egypt is highly dependent on the import of wheat, 50% of the wheat demand is met by import.

In Egypt, water scarcity and mediocre yield are two issues that keep the majority of people working in the agricultural sector in poverty. Water is scarce as the annual precipitation is less than 250mm leading to most farming to be irrigated. The water comes from the Nile river. However, available irrigation water per farmer is rather low due to population growth. Thus, due to clay soil and the use of flood irrigation, water logging and uneven water distribution over the field lead to salinization of the soil, harming the farmer's yields. Furthermore, the latter is caused by the lack of water, insufficient use of fertilizers and the use of relatively low-quality seeds. In particular, fertilizers are expensive leading to an insufficient and poor application of fertilizers.

In effect, the core objective of MRB-technology package is to fit within this context and realize more output with less input, consequently improving involved livelihoods. Indeed, MRB improves farmers' resilience with increased water and nutrient efficiency. The adopters of MRB receive benefits from direct effects such as improvement in their livelihoods, a decreased workload, increased yields and more efficient use of resources (water, fertilizer and seeds).

The first stage research and designing of MRB-technology was done in 2003. Introductions and pilots of the technology were designed together with regular farmers in the Nile Delta-area, from 2010 until 2013. In 2015, MRB-technology was proven beneficial permitting out-scaling. Thanks to the shown potential of MRB-technology and Egypt's reliance on foreign countries for water and wheat, that MRB-technology has become a strong component of Egypt's national wheat campaign. The Egyptian Government aims to cultivate 2 million acres of wheat under MRB-technology, by 2022.

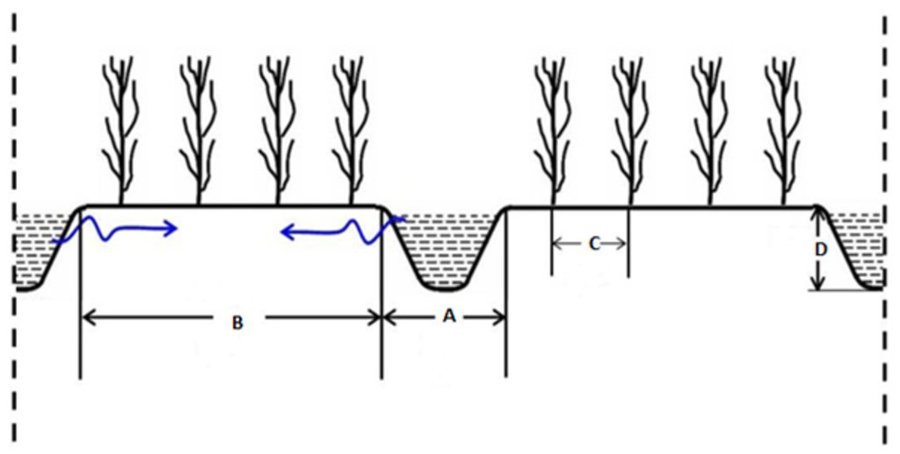

MRB-technology raises the seedbed simultaneously seeding wheat, consequently creating furrows, of which the length depend on the dimensions of the farm- field. The inter- furrow spacing and the width depends on the type of crop planted and on the soil type. The field/terrain may not exceed a slope of 5%. This allows water to infiltrate, reach the end of the furrow and for safe run-off, preventing water-logging. So, to implement MRB-technology, the field might be levelled prior to implementation, but this is often not the case as MRB is designed to local conditions, and most fields already have a slope of less than 5%. The practice of the machine requires a loose soil, so it is required that the field is ploughed prior to seeding, and therefore MRB is not seen as a type of ploughing. If the field preparation is done, a MRB-machine can start seeding and raising the seedbed. Specific characteristics for MRB-technology with respect to conventional seeding, is that seeding and raising seedbeds are done simultaneously. Raising seedbeds mechanically saves 80% of the workload with respect to manually raising seedbeds. The after-harvest practice depends on the farmer preference, as some farmers prefer letting the stubble grazed, while others clear the field. The after-harvest practices are thus independent with respect to MRB.

In addition, to complement the Mechanized Raised Bed, High Quality Seeds are offered. These are beneficial as they yield higher than the regular wheat seeds. Nevertheless, the machine can also be practiced with regular wheat seeds, if the high-quality seeds are found too expensive by the farmer. The High Quality Sees are hybrid, and need to be replaced after three years to ensure high quality.

The technology has significant positive impacts for local farmers as applied water is saved by 25%, water pumping costs decreased by 25%, seed rate reduced by 50%, farming costs decreased by 30%, fertilizer use efficiency increased by 30%, and crop yield increased by 15-30% with respect to conventional farming. On overall, it is estimated that farming under MRB is about 1/3 of the cost with respect to conventional farming. Manually raising seedbeds was considered too expensive due to the required amount of labour. Thus, regular flood irrigation was practiced. Practically, this results in full surface flooding of the field. This has significantly higher evaporation hence increasing salinization, as opposed to furrow irrigation through raised seedbeds. Also, because water is well distributed over the field due to the furrows (reducing water stress and water logging), there is less leaching of the nutrient hence increased nutrient-efficiency. The raised seedbeds allow excess water, in case of a heavy rainfall event or over-irrigating, to safely run-off. These features of better water disposal and reduced evaporation makes MRB-technology well suited with respect to climate change, which leads to more concentrated rainfall events and increased temperature hence increased evaporation. In addition, as MRB prevents e.g. waterlogging it prevents land degradation (e.g. salinization).

Therefore, livelihoods of farmers who have adopted this technology have been greatly improved. Farmers who have adopted MRB, agree that MRB is affordable, easy to apply, improves production and is cost saving. Furthermore, since this technology increases irrigation efficiency , it can mitigate existing upstream-downstream issues in terms of availability, as there is more available irrigation water. Also, as MRB-technology is currently out scaled, it creates employment opportunities since MRB-machines are locally produced from scratch.

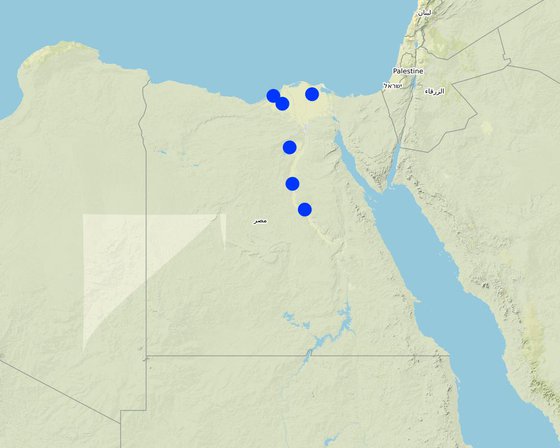

Lieu: Sharkia, Dakahlia, Beheira, Fayoum, Minya and Asuit, Egypte

Nbr de sites de la Technologie analysés: > 1000 sites

Diffusion de la Technologie: répartie uniformément sur une zone (approx. 1-10 km2)

Dans des zones protégées en permanence ?: Non

Date de mise en oeuvre: 2003

Type d'introduction

| Spécifiez les intrants | Unité | Quantité | Coûts par unité (dollars américains) | Coût total par intrant (dollars américains) | % des coût supporté par les exploitants des terres |

| Equipements | |||||

| MRB-Machine | Machine | 1,0 | 6000,0 | 6000,0 | 100,0 |

| Coût total de mise en place de la Technologie | 6'000.0 | ||||

| Coût total de mise en place de la Technologie en dollars américains (USD) | 6'000.0 | ||||

| Spécifiez les intrants | Unité | Quantité | Coûts par unité (dollars américains) | Coût total par intrant (dollars américains) | % des coût supporté par les exploitants des terres |

| Main d'œuvre | |||||

| Pesticide and herbicide application | Person-Day | 2,0 | 6,0 | 12,0 | 100,0 |

| Field Preparation and Raising Seedbeds | Person-Day | 2,0 | 100,0 | ||

| Fertilizer Application | Person-Day | 1,0 | 7,0 | 7,0 | 100,0 |

| Irrigation Management | Person-Day | 5,0 | 7,0 | 35,0 | 100,0 |

| Equipements | |||||

| Combine (harvesting) | Machine Day | 1,0 | 64,0 | 64,0 | 100,0 |

| MRB | Machine-Day | 1,0 | 10,0 | 10,0 | 100,0 |

| Tractor (Raising Seedbed) | Machine-Day | 1,0 | 17,0 | 17,0 | 100,0 |

| Sprayer | Machine-Day | 1,0 | 20,0 | 20,0 | 100,0 |

| Plough | Machine-Day | 1,0 | 32,0 | 32,0 | 100,0 |

| Tractor (Field Preparation) | Machine-Day | 1,0 | 32,0 | 32,0 | 100,0 |

| Matériel végétal | |||||

| High Yield Seeds | Kilogram | 45,0 | 0,6 | 27,0 | 100,0 |

| Engrais et biocides | |||||

| Fertilizer | Kilogram | 150,0 | 0,26 | 39,0 | 100,0 |

| Herbicide | Kilogram | 1,0 | 9,5 | 9,5 | 100,0 |

| Pesticide | Kilogram | 2,0 | 7,0 | 14,0 | 100,0 |

| Matériaux de construction | |||||

| Water (Irrigation Event) | 350m^3 | 20,0 | 8,0 | 160,0 | 100,0 |

| Autre | |||||

| Harvesting | Person-Day | 5,0 | 7,0 | 35,0 | 100,0 |

| Maintenance Raised Seedbed | Person-Day | 8,0 | 7,0 | 56,0 | 100,0 |

| Coût total d'entretien de la Technologie | 569.5 | ||||

| Coût total d'entretien de la Technologie en dollars américains (USD) | 569.5 | ||||

In the Nile Delta, the MRB-technology is used on very large area with many different farmers, therefore it is hard to generalize the aspects of the Health and Education since these are highly related to the income of a farm.

Quantité avant la GDT: None

Quantité après la GDT: +20%-30%

The yield is increased due to reduced water stress and because of the use of improved wheat varieties.

The quality of the crops is increased due to reduced water stress.

This decrease as the impact of intense rainfall events is reduced as consequence of safe disposal through furrows.

The demand of irrigation water is reduced because the efficiency of it is increased i.e. water is applied more effectively.

50% less seed rate. 20% higher fertilizer efficiency.

Because of higher yield and less input

The workload was reduced by 80% for mechanized seedbed raising (MRB) compared to manual seedbed raising.

Run-off occurs more easily with respect to traditional practices. This is positive, since this prevent water-logging.

Compared to previous border/field irrigation, the water infiltrates easier, and is concentrated more. This leads to a decrease in evaporation.

Due to better infiltration, the fertilizers are used more efficient.

Salinity is decreased because evaporation and water logging is reduced.

The impact of a flood is reduced because the excess water is able to safely run-off through the established furrows.

Due to the increased irrigation water efficiency, there is relatively more water available to desirably flood (border/surface irrigation/ MRB) farm fields downstream