Bioresource Center (BRC) is a community-led enterprise to produce bio-inputs and compost from locally available bioresources for improving soil health and fertility, managing pest and disease, and meeting the nutrient requirement for the crops. BRCs have been envisaged as a potential enterprise solution to meet the requirements of small and marginal farmers who do not have time and resources to make their own bio-inputs and composting material. Such farmers can purchase the bio-inputs at very affordable prices from the BRCs being operated by either individual entrepreneurs or community-based institutions of male and female farmers.

Essentially it is an enterprise-led platform that can create the necessary conditions to scale the adoption of better farming practices. The technology for bioresource units is applied in both natural and human environments to promote sustainable agriculture and improve livelihoods in rural communities. The establishment and maintenance of a bioresource unit require inputs such as organic waste materials, earthworms, inoculants, and water, as well as activities such as vermicomposting, biofertilizer and biopesticide production, training and capacity building, and monitoring and evaluation.

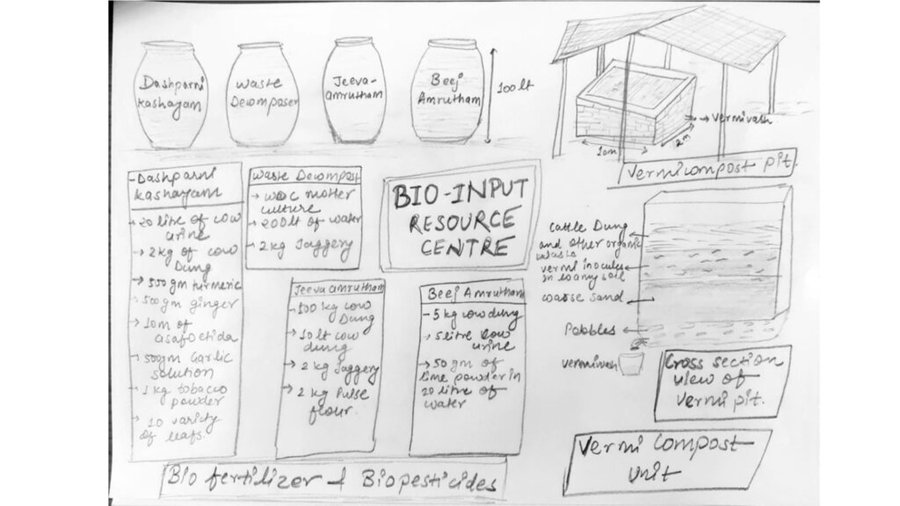

The technological inputs produced include various type of tried and tested local formulations like microbial preparations such as Jeevamrut (Soil life elixir), Ghana Jeevamrith(compact and aggregated form of Soil Life Elixir), Beejamrut (Microbial Seed Dressing), Waste Decomposer, etc.; botanical decoctions like Panchagavya ( 5 cow based products formulation - Milk, Curd, cow-urine, cow-dung, ghee), Dashparni (Extract of 10 leaves available locally), Neemastra (Extarct of Neem leaves and seeds (Azadirachta indica), Brahmastra (Referes to the highly effective pest controlling material made out of chilli, garlic and other local materials), agniastra (Refers to the fire powering material for controlling pest), NSKE (Neem seed kernel extract) ; and biopesticides cultures like Beauveria, Verticillium, Trichoderma, Pseudo-monas, NPV formulations/cultures. Beyond this, the platform enables the supply of seeds of green manuring crops, vermiculture/compost, Neem / karanj cake, Cow dung/cow urine, briquets, seeds/seedlings of trap crops, etc. For a detailed list of different sub-technologies - preparations, their ingredients and processing one can refer to BIO-INPUT RESOURCE CENTER MANUAL FROM NATIONAL COALITION FOR NATURAL FARMING at: (https://indiaclimatecollaborative.org/wp-content/uploads/2022/09/BRC-Technical-manual.pdf)

This technology does not require much investment and material. 2-3 plastic containers of 200 litres and 2-3 containers of 100 litres or any other locally available utensil are good enough to make these bio-inputs. The preparation method for each of the inputs is a bit different from each other, while some of the inputs are being prepared by extracting the paste from leaves or other materials like chilli, garlic etc, others are prepared by mixing them with cow dung and cow urine. Cow urine is one of the most important substances for preparing these inputs. The urine of indigenous cows are considered more effective for preparing these inputs. The document shared above can be refereed to for the preparation method of each of the bio-inputs.

The bioresource unit technology has numerous benefits and impacts, including improved soil health, reduced dependence on synthetic inputs, increased crop yields, reduced environmental impact, enhanced biodiversity, reduced greenhouse gas emissions, and improved human health. Land users generally appreciate the benefits of the bioresource unit technology, particularly its cost-effectiveness, improved soil health, and reduced environmental impact. However, there are also challenges related to the labor-intensiveness of the technology, the need for technical knowledge, and the dependence on local resources.

By using natural inputs and locally available resources, this technology can help to create a more sustainable and equitable food system for people and for land also. These functions contribute to a healthier environment, healthier crops, and healthier communities.

ទីតាំង: Bichhiya Block, Mandla District, Madhya Pradesh, Madhya Pradesh, ប្រទេសឥណ្ឌា

ចំនួនទីកន្លែងបច្ចេកទេស ដែលវិភាគ: 10-100 កន្លែង

ការសាយភាយនៃបច្ចេកទេស: អនុវត្តនៅកន្លែងជាក់លាក់មួយ/ ប្រមូលផ្តុំនៅតំបន់តូចៗ

តើស្ថិតក្នុងតំបន់ការពារអចិន្ត្រៃយ៍?: ទេ

កាលបរិច្ឆេទនៃការអនុវត្ត: 2018

ប្រភេទនៃការណែនាំឱ្យអនុវត្តន៍៖

| បញ្ជាក់ពីធាតុចូល | ឯកតា | បរិមាណ | ថ្លៃដើមក្នុងមួយឯកតា (មិនមាន) | ថ្លៃធាតុចូលសរុប (មិនមាន) | % នៃថ្លៃដើមដែលចំណាយដោយអ្នកប្រើប្រាស់ដី |

| កម្លាំងពលកម្ម | |||||

| Digging for vermicompost pit | piece | 2,0 | 1000,0 | 2000,0 | 100,0 |

| Construction of vermicompost pit | piece | 2,0 | 4000,0 | 8000,0 | 100,0 |

| សម្ភារៈ | |||||

| Drum 500 lts | piece | 5,0 | 600,0 | 3000,0 | 100,0 |

| សម្ភារៈដាំដុះ | |||||

| Pulse flour | Kg | 3,0 | 70,0 | 210,0 | 100,0 |

| Jageery | Kg | 3,0 | 60,0 | 180,0 | 100,0 |

| Turmeric | Kg | 0,5 | 100,0 | 50,0 | 100,0 |

| Ginger paste | Kg | 0,5 | 120,0 | 60,0 | 100,0 |

| Asafoetida | Gramm | 10,0 | 3,0 | 30,0 | 100,0 |

| Chillies | Kg | 1,0 | 100,0 | 100,0 | 100,0 |

| Garlic | Kg | 0,5 | 160,0 | 80,0 | 100,0 |

| Tobbaco | Kg | 0,5 | 200,0 | 100,0 | 100,0 |

| ជី និងសារធាតុពុល | |||||

| Cow dung | Kg | 120,0 | 2,0 | 240,0 | 100,0 |

| Cow urine | Litre | 25,0 | 5,0 | 125,0 | 100,0 |

| Lime | Gramm | 50,0 | 0,25 | 12,5 | 100,0 |

| Farm Yard Manure for Vermicompost | Kg | 1000,0 | 10,0 | 10000,0 | 100,0 |

| សម្ភារៈសាងសង់ | |||||

| Brick | Piece | 100,0 | 10,0 | 1000,0 | 100,0 |

| Cement | Sack | 3,0 | 300,0 | 900,0 | 100,0 |

| Stone | Sack | 2,0 | 500,0 | 1000,0 | 100,0 |

| ផ្សេងៗ | |||||

| Vermi inocules | Kg | 40,0 | 450,0 | 18000,0 | 100,0 |

| ថ្លៃដើមសរុបក្នុងការបង្កើតបច្ចេកទេស | 45'087.5 | ||||

| ថ្លៃដើមសរុបក្នុងការបង្កើតបច្ចេកទេសគិតជាដុល្លារ | 549.85 | ||||

| បញ្ជាក់ពីធាតុចូល | ឯកតា | បរិមាណ | ថ្លៃដើមក្នុងមួយឯកតា (មិនមាន) | ថ្លៃធាតុចូលសរុប (មិនមាន) | % នៃថ្លៃដើមដែលចំណាយដោយអ្នកប្រើប្រាស់ដី |

| កម្លាំងពលកម្ម | |||||

| Preparation of bio-inputs | Person days | 50,0 | 200,0 | 10000,0 | 100,0 |

| Packaging, marketing | Person days | 10,0 | 250,0 | 2500,0 | 100,0 |

| ជី និងសារធាតុពុល | |||||

| Cow dung or FYM for filling pit | Kg | 100,0 | 10,0 | 1000,0 | 100,0 |

| Different material to prepare bio-inputs | kg | 200,0 | 15,0 | 3000,0 | 100,0 |

| ផ្សេងៗ | |||||

| Packaging and Selling | Sack | 100,0 | 5,0 | 500,0 | 100,0 |

| ថ្លៃដើមសរុបសម្រាប់ការថែទាំដំណាំតាមបច្ចេកទេស | 17'000.0 | ||||

| ថ្លៃដើមសរុបសម្រាប់ការថែទាំដំណាំតាមបច្ចេកទេសគិតជាដុល្លារ | 207.32 | ||||

The use of compost, bio-fertilisers and other nutrient-rich material has improved farm productivity to a great extent

Improvement in crop quality such as size of the grains and vegetables, nutrient content, their aroma has improved due to application of inputs made at BRC

The local material including the local seeds are more resilient to the extreme climatic events and offer a reduced risk to the farmers

Use of local materials, low-tech home-based processing, and open source availability of technology enables farmers to produce their organic inputs at home essentially only costing capital such as plastic container and labour, thus improving the accessibility of good farming inputs to even disadvantaged groups such as small farmers, marginalised communities, landless farmers, ultra-poor, etc.

Farmers have reported of getting better prices for their produces produced with low or no chemical inputs

BRC as an enterprise activity offered an additional source of income to the farmers

Lesser use of chemical fertilizers and pesticides improve the negative impact of these on human and animal health

Cultural opportuities develop through livestock integration, concoction preparations and an improvemetn of the local economy

Use of chemical based intensive farming has proven to be disastrous for water quality and strenuous for water quantity. The BRCs help farmers adopt biological means of improving fertility and reducing pest damage and have no long-term polluting effect on groundwater and canal resources. Adoption of sustainable agriculture practices that effectively substitute chemicals, improve as well natural resource cycles have been shown to improve water availability in the field and thus also improve water use efficiency.

Reduced usage of chemical pesticides prevent loss of beneficial insects and micro organisms, thus improve the population of beneficial species

Reduced usage of chemical pesticides prevent loss of beneficial insects and micro organisms, thus improve the overall farm diversity

This technology is meant for pest/disease control purposes. The usage of these inputs is very effective in controlling the pest and diseases.

Emission reductions happen through substitution of chemical inputs. Agri chemicals have high emission intensity in production, transportation and use. Studies show that the use of urea contributes to higher methane emissions because of ammonia decomposition.

Carbon sequestration benefits are also achieved because of the increase in SOC by adopting natural inputs, higher photosynthetic efficiency, more microbial carbon use efficiency and improved residue cycling.

Adoption of this tech means reduced chemical runoff, better biodiversity supporting neighbouring fields and providing other ecosystem services.

Emission reductions happen through substitution of chemical inputs. Agri chemicals have high emission intensity in production, transportation and use. Studies show that the use of urea contributes to higher methane emissions because of ammonia decomposition.

Carbon sequestration benefits are also achieved because of increase in SOC by adopting natural inputs, higher photosynthetic efficiency, more microbial carbon use efficiency and improved residue cycling.