Domestic biogas plants convert livestock manure into biogas and bio-slurry, a form of organic fertilizer (fermented manure). Biogas is a renewable energy or gas produced by the breakdown of organic matter in the absence of oxygen. Most people in Uganda, especially in rural areas, don’t have access to electricity and mostly rely on firewood and charcoal (mostly in urban areas). This has led to depletion of forests since these forests are the main supply of wood fuel. The domestic biogas technique uses fresh cow dung to produce methane gas for lighting and heating.

This technology is viable for smallholder farmers with livestock that are capable of producing 25 kg of fresh dung per day, typically about five indigenous cows. This makes the technology suitable for smallholders in developing countries. Fresh cow dung is collected and mixed with water at a ratio of 1:1, depending on the thickness of the dung, to produce a free-flowing mixture. The mixture is poured into the digester where microbes break it down under an oxygen-free environment and in the process release methane gas which is harvested in a cylinder and piped straight into the home for lighting and/ or heating.

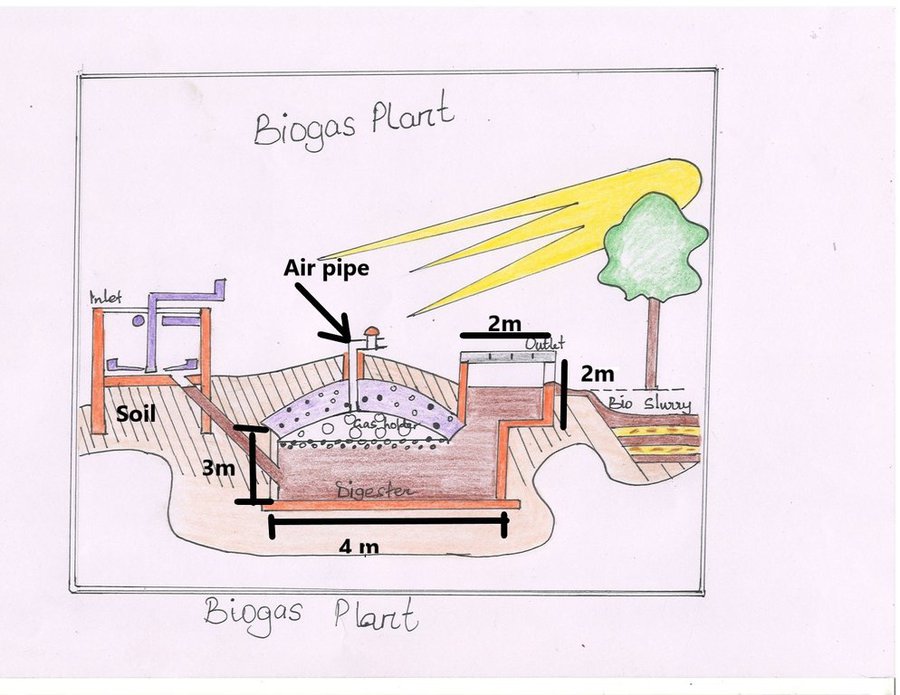

Dimensions for the Digester (4m in diameter and 3 m in depth). Overflow tank/ Outlet is 2 meters by 2 meters. Materials used in the construction of the plant include sand, cement, bricks, iron rods, gravel and water. Biogas stove, lamp and its appliances and gas controller or pressure gauge are connected after the construction of the biogas plant which can be purchased from specified outlets on the urban markets.

Production and use of biogas protects the environment through reduced tree cutting and emission of harmful greenhouse gases (GHG). It also eases the workload of rural women and children by providing a safe and cheap source of fuel since it reduces the risk encountered by children and women looking for firewood and spares their time that would otherwise be spent in the process. The bi-product (bio-slurry) removed from the digester at the end of the process is used as organic fertilizer which boosts crop productivity and is a highly nutritious feed supplement for animals.

The technology has safety issues especially on the side of children when it comes to the flammable gas.

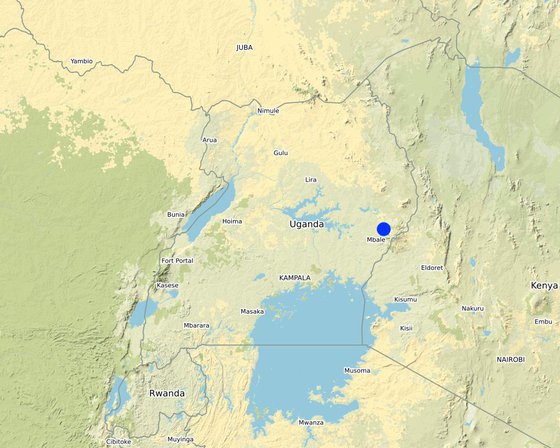

ສະຖານທີ່: Sisiyi Sub county, Gibuzale Parish, Bulabuli District, Eastern Uganda, ອູເຈນດາ

ຈໍານວນ ພື້ນທີ່ ທີ່ໃຊ້ ເຕັກໂນໂລຢີ ທີ່ໄດ້ວິເຄາະ: ພື້ນທີ່ດຽວ

ການແຜ່ກະຈາຍຂອງເຕັກໂນໂລຢີ: ນໍາໃຊ້ໃນຈຸດສະເພາະ / ແນໃສ່ນໍາໃຊ້ໃນພື້ນທີ່ຂະໜາດນ້ອຍ

ວັນທີຂອງການປະຕິບັດ: 2016

ປະເພດຂອງການນໍາສະເໜີ

| ລະບຸ ປັດໃຈ ນໍາເຂົ້າ ໃນການຜະລີດ | ຫົວໜ່ວຍ | ປະລິມານ | ຕົ້ນທຶນ ຕໍ່ຫົວໜ່ວຍ (ໂດລາສະຫະລັດ) | ຕົ້ນທຶນທັງໝົດ ຂອງປັດໃຈຂາເຂົ້າ ໃນການຜະລິດ (ໂດລາສະຫະລັດ) | % ຂອງຕົ້ນທຶນທັງໝົດ ທີ່ຜູ້ນໍາໃຊ້ທີ່ດິນ ໃຊ້ຈ່າຍເອງ |

| ແຮງງານ | |||||

| Man labour (Digging the holes)) | Person-days | 2.0 | 13.89 | 27.78 | 50.0 |

| Man labour (Building) | person-days | 20.0 | 4.17 | 83.4 | 50.0 |

| ອຸປະກອນ | |||||

| Stove | piece | 1.0 | 27.78 | 27.78 | 50.0 |

| Lamp | Piece | 1.0 | 27.78 | 27.78 | 100.0 |

| ວັດສະດຸກໍ່ສ້າງ | |||||

| Bricks | Piece | 700.0 | 0.042 | 29.4 | 50.0 |

| Cement | Bag (50kg) | 11.0 | 8.89 | 97.79 | 50.0 |

| Sand | Tonnes | 1.0 | 41.67 | 41.67 | 50.0 |

| Stones | Tonnes | 0.5 | 27.78 | 13.89 | 50.0 |

| ອື່ນໆ | |||||

| Pipes | piece @ 10m | 3.0 | 4.17 | 12.51 | 50.0 |

| Wire goose | Meters | 3.0 | 1.94 | 5.82 | 50.0 |

| Transportation | Trip | 3.0 | 27.78 | 83.34 | 50.0 |

| ຕົ້ນທຶນທັງໝົດ ໃນການຈັດຕັ້ງປະຕິບັດ ເຕັກໂນໂລຢີ | 451.16 | ||||

| ລະບຸ ປັດໃຈ ນໍາເຂົ້າ ໃນການຜະລີດ | ຫົວໜ່ວຍ | ປະລິມານ | ຕົ້ນທຶນ ຕໍ່ຫົວໜ່ວຍ (ໂດລາສະຫະລັດ) | ຕົ້ນທຶນທັງໝົດ ຂອງປັດໃຈຂາເຂົ້າ ໃນການຜະລິດ (ໂດລາສະຫະລັດ) | % ຂອງຕົ້ນທຶນທັງໝົດ ທີ່ຜູ້ນໍາໃຊ້ທີ່ດິນ ໃຊ້ຈ່າຍເອງ |

| ແຮງງານ | |||||

| Man Labour | persons- days | 2.0 | 1.39 | 2.78 | 100.0 |

| ອຸປະກອນ | |||||

| Mixing Basin | piece | 1.0 | 1.39 | 1.39 | 100.0 |

| ຝຸ່ນ ແລະ ຢາຊີວະພາບ | |||||

| Cow dung | kg | 40.0 | 0.028 | 1.12 | 100.0 |

| Water | Litres | 20.0 | 0.0014 | 0.03 | 100.0 |

| ຕົ້ນທຶນທັງໝົດ ທີ່ໃຊ້ໃນການບໍາລຸງຮັກສາ ເຕັກໂນໂລຢີ | 5.32 | ||||

ປະລິມານ ກ່ອນການຈັດຕັ້ງປະຕິບັດ ການຄຸ້ມຄອງ ທີ່ດິນແບບຍືນຍົງ: 800kg

ປະລີມານ ຫຼັງການຈັດຕັ້ງປະຕິບັດ ການຄຸ້ມຄອງ ທີ່ດິນແບບຍືນຍົງ: 1200kg

The land user uses the organic manure in his coffee plantation which has greatly led to increased yields.

Bigger coffee beans

Use of biogas for lighting and heating

No costs on purchase of fertilizer since the land user applies the bi-product (fermented manure) of the biogas.

ປະລິມານ ກ່ອນການຈັດຕັ້ງປະຕິບັດ ການຄຸ້ມຄອງ ທີ່ດິນແບບຍືນຍົງ: UGX 1040000

ປະລີມານ ຫຼັງການຈັດຕັ້ງປະຕິບັດ ການຄຸ້ມຄອງ ທີ່ດິນແບບຍືນຍົງ: UGX 1560000

More yields hence more incomes

No more fetching firewood for cooking

Use of biogas reduces effects of smoke inhaled through the use of firewood hence reduced lung diseases.

Increased knowledge on the use of organic manure as a sustainability practice.

Biogas use favours women and the disabled as it reduces the workload of fetching firewood especially from distant areas or forests.

The bi-product from the biogas plant is watery hence its used in the farm to moist the soil

Use of biogas reduces tree cutting

The bi- product removed from the digester at the end of the process is used as organic fertilizer

Use of organic manure supports multiplication of organic matter in the soil

The dung and urine from the animals is used as material in the biogas plant which would have been washed away by run off water into the river.

The user doesn't have to encourage on the neighbours' land to fetch firewood since biogas is now used for heating.

Reduced bad smells from the dung