The semi-intensive goat rearing practice is a compromise between extensive and intensive grazing systems limited by shortage of pasture during dry seasons with high chances of spreading diseases requiring for stall feeding goats in an semi-intensive system. The goats are kept under confinement for some period of time (weeks to months, especially during the dry seasons). During dry season, the animals are fed on maize bran; iodized salt; peelings from banana, cassava, and sweet potatoes; and improved grasses (Napier) and forages planted at the boundaries of the banana plantation, which are harvested during the period of need.

The farmer has got 2 ha of banana plantation. She grows a fodder hybrid called Napier (pennisetum perpureum) around the plantation to be used as fodder for the goats during dry season. Napier grass is a perennial grass fodder commonly called elephant Grass due to its tallness and vigorous vegetative growth. She got the Napier root cuttings from the neighbor practicing the same technology. This is grown around the banana plantation, at a spacing of 60×60cm. It produces more tillers with soft and juicy stem, free from pest and diseases and non-lodging. It can be cultivated throughout the year. Napier grasses contain 6-8% protein. Its optimum cutting interval is about 6 to 8 weeks at grass range of 60 to 90 cm, if sufficient only the tops can be cut and fed. The grass is cut into 5 to 10 cm to reduce loses.

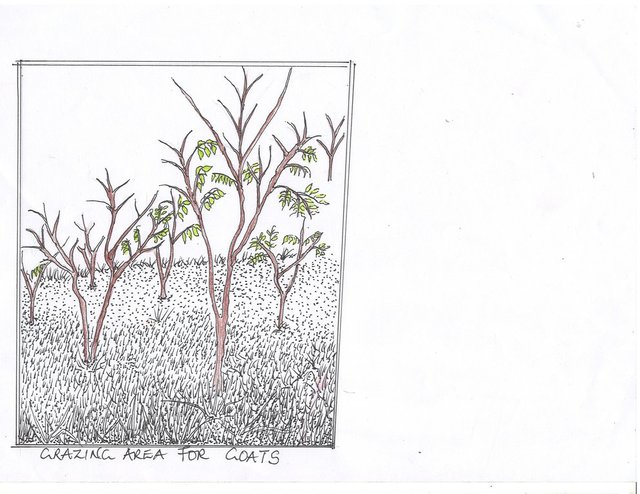

The extensive system is practiced during rainy season where the farmer grows a mixture of fodder species including Sesbania and Napier grass grown on land size of 0.5 ha. Sesbania is a fast-growing tree with regular and rounded leaves. The flowers are white and red in color according to its species but the ones at the farm are yellow. The leaves of Sesbania trees are highly palatable and mostly liked by goats. The protein content in this is about 25%. 1kg of seed was planted at a spacing of 100 cm x 100 cm. In this field Napier grass is planted in rows at a spacing of 60×60cm. The seeds for Sesbania were supplied to the farmer by the Kabarole District Production Office.

Farmers in Kabarole District use the Semi-intensive system for rearing both local and improved breeds of goats. As dry spells are increasingly becoming common, this technology helps farmers to go through the dry season with enough feed for the goats. Farmers prefer rearing goats because they don’t have complicated feeding and medical requirements. As the human population grows and land fragmentation increases, farmers in this area are now moving towards intensive feedings systems.

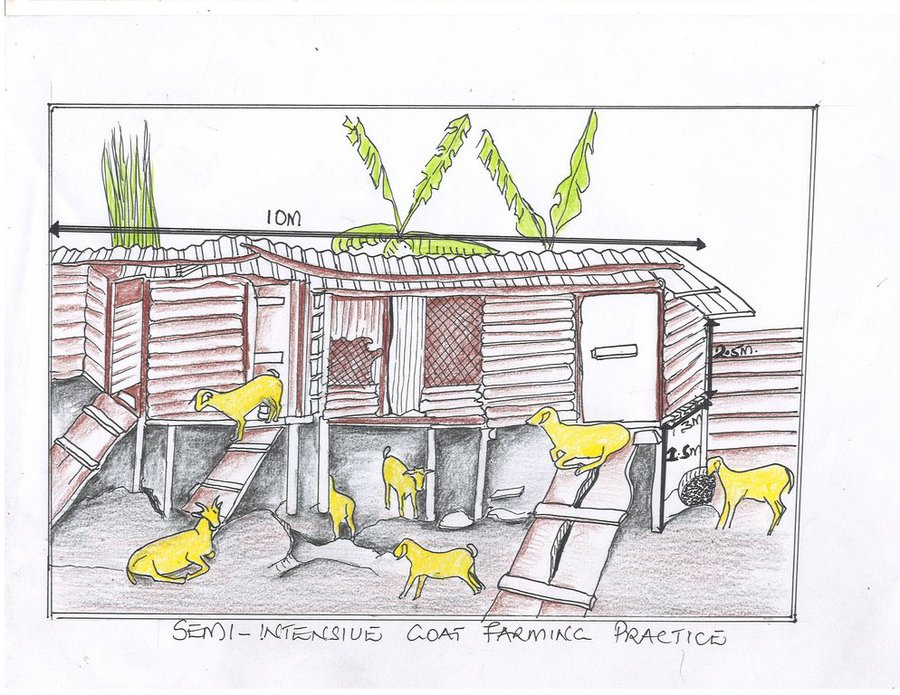

Throughout seasons of abundant forage, farmers harvest the forage together with grasses and make hay to feed the goats during the dry season when pastures are scarce. The cost of harvesting the hay is comparable to the cost of paying a herdsman in open grazing systems. Besides, the establishment of the shelter for goats is not cumbersome compared to those of other animals. The constructed structure occupies an area of about 12 ×12 meters squared with length of 10 meters and width is 3 meters. It is lifted ground to floor 1.5 meters and floor to roof by 2.5 meters. Further partitioned in 4 units and each unit measurement is 3 meters with a slope angle of 20 degrees. The Capacity of each unit is 18,17,17 and 18 goats respectively.

The shelter for the goats is made from relatively cheap materials that are readily available to the farmers. The farmer rears 70 goats on 1-acre piece of land using this technology. By planting improved forages in the grazing areas, the farmer receives increased amount of forage harvested as well as the quality of grass available to the goats during the open grazing periods and income after sale.One challenge of this technology is the dependence on family labor that is not always sufficient for all the tasks involved in the technology both at establishment and maintenance in addition to complications with of rural-urban migration of youth, thereby leaving the workload to the elderly.

Localização: Western Region, Uganda

Nº de sites de tecnologia analisados: Local único

Difusão da tecnologia: Uniformemente difundida numa área (approx. < 0,1 km2 (10 ha))

Data da implementação: 1960

Tipo de introdução

| Especifique a entrada | Unidade | Quantidade | Custos por unidade (shillings) | Custos totais por entrada (shillings) | % dos custos arcados pelos usuários da terra |

| Mão-de-obra | |||||

| Animal housing Structure construction labor | Man days | 2,0 | 25000,0 | 50000,0 | 100,0 |

| Buying kids | Kids | 20,0 | 20000,0 | 400000,0 | 100,0 |

| Equipamento | |||||

| Poles | 35,0 | 7000,0 | 245000,0 | 100,0 | |

| Iron sheets | 50,0 | 21000,0 | 1050000,0 | 100,0 | |

| Nails | Kilograms | 30,0 | 3000,0 | 90000,0 | 100,0 |

| Ropes | 20,0 | 1000,0 | 20000,0 | 100,0 | |

| Material vegetal | |||||

| Unit doors | 5,0 | 25000,0 | 125000,0 | 100,0 | |

| Custos totais para a implantação da tecnologia | 1'980'000.0 | ||||

| Especifique a entrada | Unidade | Quantidade | Custos por unidade (shillings) | Custos totais por entrada (shillings) | % dos custos arcados pelos usuários da terra |

| Mão-de-obra | |||||

| Animal Vaccine | Bottles | 2,0 | 25000,0 | 50000,0 | 100,0 |

| Iodine salt | Kilograms | 360,0 | 800,0 | 288000,0 | 100,0 |

| Labor | 100,0 | ||||

| Outros | |||||

| Stocking animal feeds | Bundles | 1300,0 | 500,0 | 650000,0 | 100,0 |

| Custos totais para a manutenção da tecnologia | 988'000.0 | ||||

Reason given is that a farmer can now comfortably pay children school fees plus take-care of the family necessities

Cut and carry method requires much labor

Manure collected from the goats shelter is piled and later applied in the garden hence increasing crop yields

Goats confined.