Contour bund combined with Sessbania sesseban, beans and manure technology in banana production is the digging and excavation of a 60cm wide by 60co deep furrow, plated Sessbania sessban along the contour bund, application of farm yard manures in a 30cm deep by 60 cm wide furrow at 30cm from the banana stool and plating beans in the space between bunds. The technology is applied on Perennial (non-woody) cropping system, supported with rain fed to prevent and mitigate land degradations. The production mode is mixed (subsistence and commercial. The technology impact should be observed on controlled soil erosion by water, reduced declining soil fertility, and increased water infiltration. To implement this technology, a total of US$ 100.41 establishment costs per hectare and US% 1,076.47 maintenance costs per hectare per year according to the introduction of the technology in 2012 By TAMP –Kagera. Small ruminants rearing are the supportive measures of the technology.

Purpose of the Technology: The major purpose of the technology is land degradation prevented in 50 ha, crop and livestock production increased by 10% to contribute on food security and livelihood improvement with a SLM. Technically the technology should control of raindrop splash, control of dispersed runoff: retain / trap, reduction of slope length, stabilisation of soil (eg by tree roots against land slides), increase in organic matter, increase in nutrient availability (supply, recycling) and increase of water infiltration.

Establishment / maintenance activities and inputs: The establishment activities includes:- First, identification and demarcation of contour line done manually using simple tool (A-frame); this is done in May. Second is the digging of a 0.6m width and 0.6m depth furrow, excavation the soils and place them on the upper side (at the smaller slope) and lower side (at the bigger slope) along the contour using chisel hand hoes, fork hand hoes spades and mattock; this is done in June. Third is to drill two rows of Sessbania sesban seeds, spaced 0.3 m between the rows; this is done in late September. Fourth is the thinning of Sessbania sesban seedlings at the average space of 15cm done manually; this is done when the seedling is at the height of. The maintenance activities include; First is to weed the whole field done manually using local made tools (kahosho); this is done twice in January to February and June to August. Second is to apply farm yard manures in the furrow of 0.3 m deep by 0.6m wide cultivated 0.60 m from the banana stool and facing the granddaughter sucker; this is done early July. Third is desuckering and detrushing of banana stools using local made tools (kihosho and rwabyo) and machete; this is done twice (February and September).Fourth is to plant beans done manually using local made tool (kahosho; this is done in March and September. Fifth is the harvesting of beans and hauling done manually; this is done twice (June and early February). Sixth is cleaning of the furrow done manually using spades; this is done twice at the end of rain seasons (January and December). Finally, harvesting of banana and Sessbania sessban is done according to the market demand.

Natural / human environment: The physical environment is characterized of sub humid climatic zone, 750-1000 mm rain falls, 1000-1500 m.a.s.l, hill slopes land form with gentle slope. The soil texture is medium (loam), Soil fertility is medium, topsoil organic matter is medium (1-3%) and soil drainage/infiltration is medium. The soil water storage capacity is medium, ground water table is 5 - 50 m, availability of surface water is medium and water quality is poor drinking water. This technology is tolerant of seasonal rainfall decrease, droughts / dry spells while sensitive to heavy rainfall events (intensities and amount). The land users applying the technology are individual / household, Small scale land users, common / average land users. The Land ownership is communal / village, individual, not titled . The Land use rights is communal (organised), and/or individual. The water use rights is open access (unorganised). The relative level of wealth is categorized as rich, which represents 4% of the land users and own 34% of the total area. The average category, which represents 64% of the land users own 64% of the total area. The poor category, which represents 32% of the

land users owns 2% of the total area.

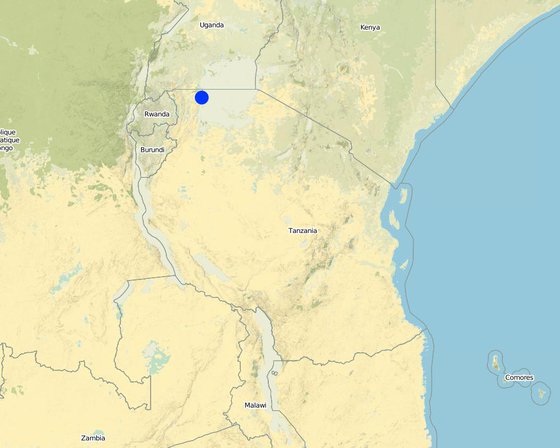

Localização: Bukoba District council, Tanzania, República Unida da Tanzânia

Nº de sites de tecnologia analisados:

Difusão da tecnologia:

Em uma área permanentemente protegida?:

Data da implementação: menos de 10 anos atrás (recentemente)

Tipo de introdução

| Especifique a entrada | Unidade | Quantidade | Custos por unidade (Tshs) | Custos totais por entrada (Tshs) | % dos custos arcados pelos usuários da terra |

| Mão-de-obra | |||||

| plant sessebania seeds by drilling along the contour bunds | Mandays | 1,0 | 1,76 | 1,76 | 100,0 |

| thin extra seedling and allow a 30cm between plants by 30cm between rows | Mandays | 1,0 | 1,76 | 1,76 | 100,0 |

| demarcate the contour line | Mandays | 1,0 | 1,76 | 1,76 | 100,0 |

| dig and excavate soils to make bunds | Mandays | 1,0 | 1,76 | 1,76 | 100,0 |

| Equipamento | |||||

| Tools | pieces | 4,0 | 2,91 | 11,64 | 100,0 |

| Material vegetal | |||||

| Seeds | kg | 0,9 | 0,588888 | 0,53 | |

| Custos totais para a implantação da tecnologia | 19.21 | ||||

| Custos totais para o estabelecimento da Tecnologia em USD | 0.01 | ||||

| Especifique a entrada | Unidade | Quantidade | Custos por unidade (Tshs) | Custos totais por entrada (Tshs) | % dos custos arcados pelos usuários da terra |

| Mão-de-obra | |||||

| Weeding the entire field prior nonseasonal. | Mandays | 6,0 | 1,76 | 10,56 | 100,0 |

| apply manure in a 60 x60 farrow along the daughter plant | Mandays | 10,0 | 1,76 | 17,6 | 100,0 |

| desuckering and detrushing banana plants | Mandays | 3,0 | 1,76 | 5,28 | 100,0 |

| lant (dibbling) beans in the space between bunds | Mandays | 3,0 | 1,76 | 5,28 | 100,0 |

| Material vegetal | |||||

| Seeds | kg | 30,0 | 0,706 | 21,18 | 100,0 |

| Fertilizantes e biocidas | |||||

| Compost/manure | tons | 1,5 | 29,413333 | 44,12 | |

| Outros | |||||

| Labour: harvest seeds | mandays | 5,0 | 1,76 | 8,8 | 100,0 |

| Labour: prune branches for goat feeds | mandays | 5,0 | 1,76 | 8,8 | 100,0 |

| Labour: remove soil sediments in the farrow | mandays | 3,0 | 1,76 | 5,28 | 100,0 |

| Custos totais para a manutenção da tecnologia | 126.9 | ||||

| Custos totais de manutenção da Tecnologia em USD | 0.07 | ||||

Quantidade anterior à GST: 5

Quantidade posterior à GST: 9

banana and beans

Quantidade anterior à GST: 0

Quantidade posterior à GST: 2

dessebania tree branches.

Quantidade anterior à GST: 14

Quantidade posterior à GST: 21

Digestable Crude Protein.

Quantidade anterior à GST: 0.05kg

Quantidade posterior à GST: 0.075kg

liveweight gain per goat kid/annum

manures costs

Increased banana and beans productivity can sustainthe house hold consuption requirement as well as selling excess to access source of animal protein and utilise a balanced diety for prosperous health.

It is very difficult to identify the contribution to improved livelihood and well-being of such juvenile technology in the area.

trashlines

trashlines and beans crops

use of trshlines and beans as crop cover

beans

sedments collcted if furrows

sessebania

manures

Trashline

run-off water retined by bund in the field insteady of running along the roadsides.