In many cases local inhabitants of rural areas depend heavily on locally available natural resources, contributing to, and accelerating deforestation. As a low cost fuel source, local households often use cow-dung and wood. Taking these from the local area contributes to decreased soil fertility and erosion processes. Most of the dung collected from livestock is burnt in a very inefficient manner for cooking, baking and heating purposes. Based upon assessments by Welthungerhilfe in 600 households (HH) who were using cow dung as the only fuel material, on average one HH uses 4.6 tons of cow dung annually when using traditional cooking stoves, 6 tons for heating and 4.5 tons for bread baking. This means almost 15.1 tons of cow dung is burnt annually per HH.

Using a simple modification of the traditional cooking stove, approximately 50 - 60% or 2.3 tons of fuel material can be saved. This saving can be further increased by the utilisation of a pressure cooker that decreases the cooking time by 50%. Not all local hot meals can be cooked with a pressure cooker but it can contribute to an additional saving of 0.7 ton of organic matter.

The introduction of a metal heat exchanger on the exhaust pipe of a cast iron stove can help save a household 3 tons of fuel material per year, the effectiveness can be further increased by the incorporation of bread baking compartment.

Further savings can be made by using straw, mud and wood to improve the thermal insulation of the exterior walls, ceiling and floor in the house.

Through the integration of all above measures approx 60% of the current usage rates of organic material used for fuel can be saved. In addition it will keep the house warmer for longer, reduce the smoke in the air, and help retain organic material in the soil.

Purpose of the Technology: The main objective of the energy efficiency technology is to address one of the root causes of the deforestation process and to improve soil fertility i.e. to decrease the demand from the local population for organic fuel. This project used a range of technologies to address this issue which in combination provided substantial savings in organic fuel.

Establishment / maintenance activities and inputs: Cooking stoves: For centuries local populations have been using traditional cooking stoves for cooking, especially during the warm seasons of the year. These were made from a mixture of mud and straw. The modification of these involves improving the aeration process during the burning of the fuel. This is achieved by putting a metallic cover with one inflow cutting and six small smoke outflow holes surrounding the cooking pot. The only input needed which is not locally available is the metallic cover.

Pressure cookers: As maintenance is required 1-2 times per season to keep the cooking stove functioning efficiently, the utilisation of pressure cookers can be easily integrated with the modified cooking stoves.

Heat exchangers: The heat exchangers installed on top of the iron ovens, can be produced by local tradesmen and need to be cleaned every 1-2 months. They have to be installed before the start of the winter season when the heating is needed.

House installation: The house insulation, using locally available materials does not need maintenance once it is installed. However, the storage of dry fruits or bread in the attic should be avoided as it could attract mice which can destroy the insulation.

Welhungerhilfe provided subsidies for all the above work, except for the heat exchangers.

Natural / human environment: The geographical area served by the project is mainly hill slopes, covered in low grade pasture fodder with wheat crops planted in loess soil. Although the soils have the potential to be very fertile, they are overused and not well managed and thus have become degraded and denuded. One of the main contributing factors to this is the removal of organic material from the biomass cycle. Trees, bushes and organic material is cut and collected to be used as fuel.

The main source of income in the area is from semi-subsistence farming, and the removal of organic material has a significant impact on their crops and livestock.

The houses are made from concrete foundations and mud bricks, these and the current stoves are all energy inefficient and fail to retain heat.

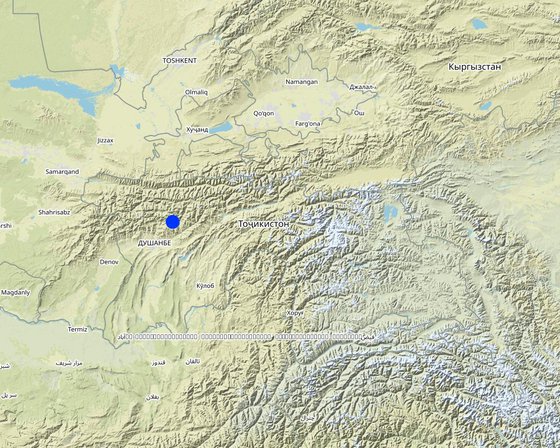

Localização: Temurmalik . Davad, Tajikistan / Khatlon, Tajiquistão

Nº de sites de tecnologia analisados:

Difusão da tecnologia: Uniformemente difundida numa área (approx. > 10.000 km2)

Em uma área permanentemente protegida?:

Data da implementação: menos de 10 anos atrás (recentemente)

Tipo de introdução

| Especifique a entrada | Unidade | Quantidade | Custos por unidade (TJS) | Custos totais por entrada (TJS) | % dos custos arcados pelos usuários da terra |

| Mão-de-obra | |||||

| Labour | per stove | 1,0 | 5,5 | 5,5 | 100,0 |

| Labour | per room | 1,0 | 37,8 | 37,8 | 100,0 |

| Material vegetal | |||||

| Wheat straw | bales | 12,0 | 4,9 | 58,8 | 100,0 |

| Material de construção | |||||

| Metallic cover | per stove | 1,0 | 5,1 | 5,1 | 34,0 |

| Earth | per stove | 1,0 | 0,5 | 0,5 | 100,0 |

| Wooden lath | per room | 1,0 | 72,0 | 72,0 | 15,0 |

| Nail, lime, brush, emalen | per room | 1,0 | 30,75 | 30,75 | 100,0 |

| Veneer and glueing silicone | per room | 1,0 | 43,8 | 43,8 | 100,0 |

| Outros | |||||

| Pressure cooker | piece | 1,0 | 22,2 | 22,2 | 80,0 |

| heat exchanger | per stove | 1,0 | 30,0 | 30,0 | 100,0 |

| Transportation cost | 1,0 | 44,0 | 44,0 | 100,0 | |

| Custos totais para a implantação da tecnologia | 350.45 | ||||

| Custos totais para o estabelecimento da Tecnologia em USD | 77.88 | ||||

| Especifique a entrada | Unidade | Quantidade | Custos por unidade (TJS) | Custos totais por entrada (TJS) | % dos custos arcados pelos usuários da terra |

| Mão-de-obra | |||||

| Labour | per stove | 1,0 | 3,3 | 3,3 | 100,0 |

| Custos totais para a manutenção da tecnologia | 3.3 | ||||

| Custos totais de manutenção da Tecnologia em USD | 0.73 | ||||

Quantidade anterior à GST: 12 t/ha

Quantidade posterior à GST: 21 t/ ha

Quantidade anterior à GST: TJS 100

Quantidade posterior à GST: TJS 1200

Not possible to cook all meals in this