Contour ridges cultivation is a seasonal water conservation and erosion control land tilling practice aiming at improving production of cassava (Manihot esculenta), improving potential of the soil and environmental function of the land. The technology is among a list of basket of choices of SLM practices recently introduced and adapted to the area by land user working in collaboration with extension officers/SLM specialists under the auspicious support of the Tras-boundary Agro-ecosystem Management Project (Kagera TAMP).

Contour ridges are cultivated in rows across a convex slope landform of average slope category lying between 5-8%. The average height of a ridge is 0.45 -0.50m, with width lying between 0.4 -0.5m, and the distance between rows is 1 meter. To be stronger, contour ridges are tied with furrows (Tiles) dug along the slope intercepting the ridges almost perpendicular. Within a cassava block farm of average size 0.5 acres, the average length of a contour ridge is approximately 30 - 35m. Within tiles, pits are dug. The distance from one pit to another is usually 5 meters. Soils from dug pit are piled on the lower side of the slope to form a supportive bund which is stabilized and made productive by planting pineapples on it. The number of pineapples (suckers) planted on each pit bund is 3-4. Tiles provide diagonal strength to the ridges, trap runoff and allow water to infiltrate and be available to the plants. Manure application is done after contour ridging by incorporating or mixing manure with soil. Manure application at a rate of 12 tons per hectare is done before cassava planting.

Purpose of the Technology: The basic tenet of this technology is to turn a poorly managed land resource that is exposed to detrimental grazing, poor agricultural practices and uncontrolled fire burning into a managed, productive agricultural land that contribute to improved agriculture production, livelihood income and ecosystems (put the triple win solution into reality).

The rural food security and income are enhanced through soil erosion control, fertility improvement, beneficial harvesting of rainfall-runoff and use of improved cassava germ-plasm (with high resilience to climatic change and diseases and no use of chemicals).

Establishment / maintenance activities and inputs: The technology is largely agronomic dominated by seasonally repeatedly activities. The dominant recurrent activities are land preparation, contour ridging cultivation, tile digging (furrow digging, pit digging, bund making and pineapple planting), manure application, cassava planting, weeding and harvesting. The inputs needed are: tools (machete, sickles, hand holes), planting materials (cassava and pineapple), manure and labour.

The average costs per hectare of this technology is 1155.48 USD. Manure application is the most cost determinant factor and accounts for 50.89% of the total costs. Average production of cassava per hectare is 7,376.32 USD. In monetary terms the average benefit to cost ratio B/C is 6.38 exemplifying viability of the technology.

Natural / human environment: Naturally the environment encompasses cropland land use type , the technology is largely agronomic, climatic zone is sub humid with 210 length of growing period, slope category is foot slopes, the dominant soil textural class is loam with a medium soil depth. On human environment the defined level of mechanization is largely hand tools, production is mixed. land ownership is largely individual not titled and there is also communally owned land.

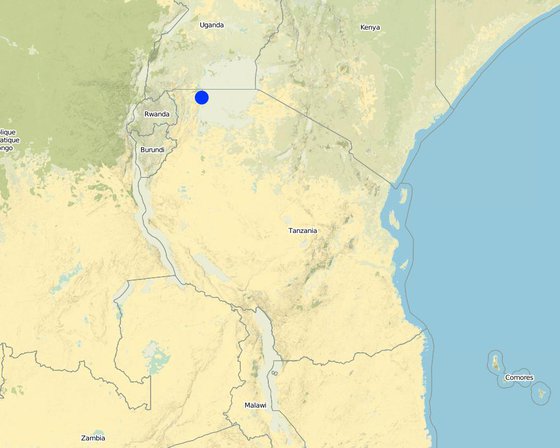

สถานที่: Bukoba rural district/Karonge, Tanzania/Kagera, แทนซาเนีย

ตำนวนการวิเคราะห์เทคโนโลยี:

การเผยแพร่ของเทคโนโลยี: กระจายไปอย่างสม่ำเสมอในพื้นที่ (approx. < 0.1 ตร.กม.(10 เฮกตาร์))

In a permanently protected area?:

วันที่ในการดำเนินการ: น้อยกว่า 10 ปี (ไม่นานนี้)

ประเภทของการแนะนำ

| ปัจจัยนำเข้า | หน่วย | ปริมาณ | ค่าใช้จ่ายต่อหน่วย (Tanzanian shillings) | ค่าใช้จ่ายทั้งหมดต่อปัจจัยนำเข้า (Tanzanian shillings) | %ของค่าใช้จ่ายที่ก่อให้เกิดขึ้นโดยผู้ใช้ที่ดิน |

| อุปกรณ์ | |||||

| Tools | pieces | 36.0 | 2.9167 | 105.0 | 100.0 |

| วัสดุด้านพืช | |||||

| cassava cuttings | 1.0 | ||||

| ปุ๋ยและสารฆ่า/ยับยั้งการเจริญเติบโตของสิ่งมีชีวิต (ไบโอไซด์) | |||||

| compost/manure | 1.0 | ||||

| ค่าใช้จ่ายทั้งหมดของการจัดตั้งเทคโนโลยี | 105.0 | ||||

| Total costs for establishment of the Technology in USD | 0.06 | ||||

| ปัจจัยนำเข้า | หน่วย | ปริมาณ | ค่าใช้จ่ายต่อหน่วย (Tanzanian shillings) | ค่าใช้จ่ายทั้งหมดต่อปัจจัยนำเข้า (Tanzanian shillings) | %ของค่าใช้จ่ายที่ก่อให้เกิดขึ้นโดยผู้ใช้ที่ดิน |

| แรงงาน | |||||

| Land preparation | person/days | 45.0 | 1.17777 | 53.0 | 100.0 |

| Contour ridging cultivation combined with tiles. | person/days | 60.0 | 1.46666 | 88.0 | 100.0 |

| Manure application | person/days | 30.0 | 1.46666 | 44.0 | 100.0 |

| Planting cassava and pineapple | person/days | 13.0 | 1.154 | 15.0 | 100.0 |

| อุปกรณ์ | |||||

| Tools | 1.0 | 100.0 | |||

| วัสดุด้านพืช | |||||

| cassava cuttings | pieces | 10000.0 | 0.017648 | 176.48 | |

| pineapple suckers | pieces | 180.0 | 0.28888888 | 52.0 | |

| ปุ๋ยและสารฆ่า/ยับยั้งการเจริญเติบโตของสิ่งมีชีวิต (ไบโอไซด์) | |||||

| Compost/manure | Tons | 12.0 | 49.0 | 588.0 | |

| อื่น ๆ | |||||

| Labour: Weeding | person/days | 26.0 | 0.577 | 15.0 | 100.0 |

| Labour: Harvesting | person/days | 26.0 | 0.7307 | 19.0 | 100.0 |

| ค่าใช้จ่ายทั้งหมดของการบำรุงรักษาสภาพเทคโนโลยี | 1'050.48 | ||||

| Total costs for maintenance of the Technology in USD | 0.62 | ||||

จำนวนก่อน SLM: 12

หลังจาก SLM: 24

จำนวนก่อน SLM: 12

หลังจาก SLM: 0

Only food

Few adopters

จำนวนก่อน SLM: 30 dollars

หลังจาก SLM: 940 dollas

Due to manue application, purchase of improved cartivars and suckers

จำนวนก่อน SLM: 600

หลังจาก SLM: 1200

Weeding is done once. Needs a lot more labour, hired labourers

จำนวนก่อน SLM: 0.3

หลังจาก SLM: 0.7

Demo site only

Very few adoption

Few widows

Increased productivity above 50% leading to increase income and farmers capacity to invest in education and health.

Close ridges

Residuals

Manure application

Residuals

Pure stand

Guarding