In the semi-arid regions of Morocco agricultural production is unstable, and yields are declining as consequence of climate change. Climate change leads to more irregular rainfall and more frequent extreme weather events. There is a need, where possible, to intensify agricultural systems while improving food security - through increasing the resilience of the overall system.

Cultivating lentils is common practice in rural Morocco. To intensify this cropping system, taking into account the effects of climate change, the International Centre for Agricultural Research Dry Areas (ICARDA) introduced quinoa into the common lentil production system. Importantly, quinoa does not affect the yields of lentil because it does not significantly compete for water and nutrients. With two crops harvested from the same piece of land, overall farm profit increases. Furthermore, the cultivation of two crops creates a more resilient overall system because the farmer is not dependent on one single crop. Additionally, as quinoa is harvested later than lentil, the soil is covered for a longer period, consequently protecting it from degradation, hence soil quality is improved. In addition, lentils are leguminous, fixing nitrogen in the soil, thus improving soil conditions for growth.

However the technology has some potential drawbacks. Firstly, in Morocco, the market for quinoa is not well developed, hence achieving a good market price could be problematic if planted at scale. Secondly, in years of extreme droughts, quinoa requires supplementary irrigation, especially during crop establishment. This is often inaccessible, resulting in poor crop establishment and low yield. Thirdly, if planted in small plots there may be risks of free grazing livestock as well as pest and insect infestations. This can be overcome by community farming and pest control.

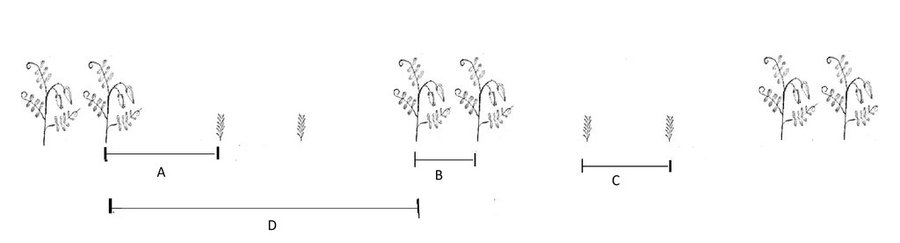

In 2020 and 2021, ICARDA tested this Diversified Cropping System on a trial field of half a hectare, in an area with average annual precipitation of 400 mm. DCS is implemented in the following order of activities. The field is prepared by ploughing. In December, lentils are mechanically seeded. Two rows of lentils are planted 15 cm apart. The spacing between each two-row pair is roughly 90 cm. Compound fertilizer is applied during the seeding. In January, a herbicide is sprayed to control grassy weeds. The field is mechanically weeded twice, in mid-January and then again in February.

The quinoa is then seeded at the end of February: also in paired lines (two rows at 20 cm apart) and also with compound fertilizer. Each pair of quinoa lines is planted between pairs of lentils. Because the quinoa is planted within an already growing crop of lentils, this form of intercropping is termed "relay planting".

The quinoa is manually weeded in March. In April, the lentils are manually harvested and mechanically threshed. A single spray of insecticide is applied in April-May. Finally, in June, the quinoa is mechanically harvested.

This documentation illustrated an ICARDA innovation which is accessible since there are no establishment events and costs. This Diversified Cropping System improves a traditional system by introducing an additional crop, resulting in better farm income and more resilience.

สถานที่: Merchouch, โมร็อกโก

ตำนวนการวิเคราะห์เทคโนโลยี: พื้นที่เดี่ยว

การเผยแพร่ของเทคโนโลยี: กระจายไปอย่างสม่ำเสมอในพื้นที่ (approx. < 0.1 ตร.กม.(10 เฮกตาร์))

In a permanently protected area?: ไม่ใช่

วันที่ในการดำเนินการ: 2020

ประเภทของการแนะนำ

| ปัจจัยนำเข้า | หน่วย | ปริมาณ | ค่าใช้จ่ายต่อหน่วย (Moroccan Dihram (MAD)) | ค่าใช้จ่ายทั้งหมดต่อปัจจัยนำเข้า (Moroccan Dihram (MAD)) | %ของค่าใช้จ่ายที่ก่อให้เกิดขึ้นโดยผู้ใช้ที่ดิน |

| แรงงาน | |||||

| Lentil Harvesting | Person-Days | 10.0 | 75.0 | 750.0 | 100.0 |

| Weeding (lentil) | Person-Days | 10.0 | 75.0 | 750.0 | 100.0 |

| Weeding (quinoa) | Person-Days | 20.0 | 75.0 | 1500.0 | 100.0 |

| อุปกรณ์ | |||||

| Lentil Thresher | Machine-Hours | 2.0 | 150.0 | 300.0 | 100.0 |

| Quinoa Harvester | Machine-Hours | 1.0 | 500.0 | 500.0 | 100.0 |

| Lentil Seeder | Machine-Hours | 1.0 | 150.0 | 150.0 | 100.0 |

| Quinoa Seeder | Machine-Hours | 1.0 | 150.0 | 150.0 | 100.0 |

| Sprayer | Machine-Hours | 3.0 | 60.0 | 180.0 | 100.0 |

| Weeder | Machine-Hours | 2.0 | 100.0 | 200.0 | 100.0 |

| วัสดุด้านพืช | |||||

| Lentil Seeds | Kilogram | 45.0 | 8.0 | 360.0 | 100.0 |

| Quinoa Seeds | Kilogram | 3.5 | 40.0 | 140.0 | 100.0 |

| ปุ๋ยและสารฆ่า/ยับยั้งการเจริญเติบโตของสิ่งมีชีวิต (ไบโอไซด์) | |||||

| NPK 10-20-20 (for Lentil) | Kilogram | 100.0 | 3.0 | 300.0 | 100.0 |

| NPK 15-15-15 (for Quinoa) | Kilogram | 150.0 | 3.0 | 450.0 | 100.0 |

| Herbicide (for Lentil) | Liter | 1.0 | 170.0 | 170.0 | 100.0 |

| Insecticide (for Quinoa) | Milliliter | 50.0 | 1.5 | 75.0 | 100.0 |

| Fungicide (for Lentil) | Liter | 0.5 | 150.0 | 75.0 | 100.0 |

| ค่าใช้จ่ายทั้งหมดของการบำรุงรักษาสภาพเทคโนโลยี | 6'050.0 | ||||

| Total costs for maintenance of the Technology in USD | 672.22 | ||||