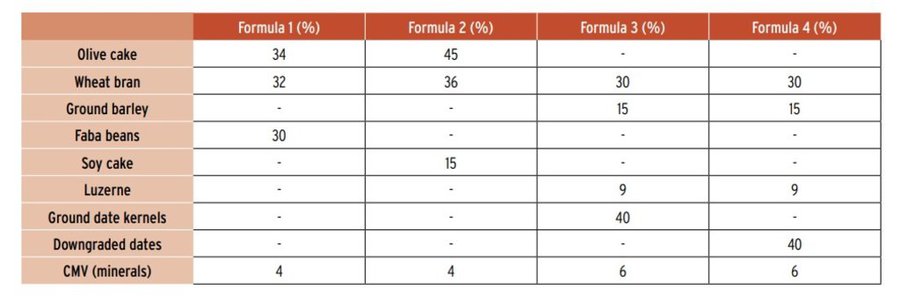

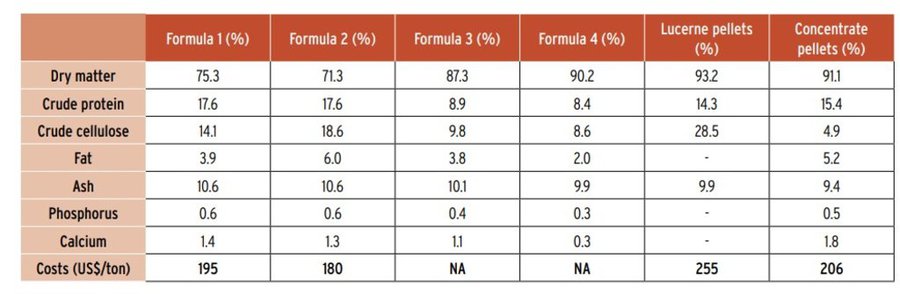

In Tunisia, there are many agropastoralists who are dependent on expensive and imported feed pellets to improve livestock quality and to supplement feed shortages. Risks of relative shortages are likely to increase due to climate change. Simultaneously there are many discarded by-products from (local) agrofood supply chains such as olive cakes, date kernels, and downgraded dates, which contain good levels of nutrients. ICARDA saw an opportunity and, together with local partners, a machine was imported that is able to compress nutritious by-products into pellets. In addition to the machine, ICARDA and OEP experimented with feasible inputs and different ratios, considering local availability as well. It achieved highly dense and nutritious feed pellets from local available inputs, with similar quality to the imported pellets. There are currently two pelletizers on the market, a large model with a maximum capacity of 500 kilograms of pellets per hour, and a more affordable small pelletizer producing 125 kilogram per hour. Four formulae are recommended (see section 4.1). Two have olive cake as the main ingredient and the other two have date palm by-products as the key input. All formulae have an average protein content of 17% which is higher than imported pellets. The benefits include:

-Possibility of overcoming periods of fodder shortages

-Less dependence on expensive imports and price volatility

-Source of nutritious feed and improving livestock quality while reduced feeding costs

-Less pressure on grazing land and thereby reducing land degradation

-Joint purchase and use of a pelletizer by a farmer organization, improves social cohesion

-The pellets generate income and employment for the farmer organization

However the land users have experience challenges when acquiring permits for pellet production and electricity. In addition, there may be by-products supply constraints.

Information and data presented is partly made available through the projects “CRP livestock “Feed and Forages”” funded by CGIAR, and “SWC@scale” funded by GIZ. Projects were managed by the International Center for Agricultural Research in the Dry Areas (ICARDA) and implemented in Tunisia in collaboration with the Livestock and Pasture Office (OEP). Thus far, pelletizers have been made available by the CIGAR Research Program on Livestock (3 large and 2 small) and the German Organization for International Cooperation (GIZ) (a large and 2 small).

สถานที่: ตูนิเซีย

ตำนวนการวิเคราะห์เทคโนโลยี: 2-10 แห่ง

การเผยแพร่ของเทคโนโลยี: ใช้ ณ จุดที่เฉพาะเจาะจงหรือเน้นไปยังบริเวณพื้นที่ขนาดเล็ก

In a permanently protected area?: ไม่ใช่

วันที่ในการดำเนินการ: 2019

ประเภทของการแนะนำ

| ปัจจัยนำเข้า | หน่วย | ปริมาณ | ค่าใช้จ่ายต่อหน่วย (Tunisian Dinar) | ค่าใช้จ่ายทั้งหมดต่อปัจจัยนำเข้า (Tunisian Dinar) | %ของค่าใช้จ่ายที่ก่อให้เกิดขึ้นโดยผู้ใช้ที่ดิน |

| อุปกรณ์ | |||||

| Large Pelletizer | 1.0 | 9000.0 | 9000.0 | ||

| ค่าใช้จ่ายทั้งหมดของการจัดตั้งเทคโนโลยี | 9'000.0 | ||||

| Total costs for establishment of the Technology in USD | 3'000.0 | ||||

| ปัจจัยนำเข้า | หน่วย | ปริมาณ | ค่าใช้จ่ายต่อหน่วย (Tunisian Dinar) | ค่าใช้จ่ายทั้งหมดต่อปัจจัยนำเข้า (Tunisian Dinar) | %ของค่าใช้จ่ายที่ก่อให้เกิดขึ้นโดยผู้ใช้ที่ดิน |

| แรงงาน | |||||

| Using the pelletizer | Person-hour | 2.0 | 3.0 | 6.0 | |

| วัสดุด้านพืช | |||||

| Olive cake | Kilogram | 340.0 | 0.07 | 23.8 | |

| wheat bran | Kilogram | 320.0 | 0.25 | 80.0 | |

| Faba Beans | Kilogram | 300.0 | 1.5 | 450.0 | |

| Minerals | Kilogram | 40.0 | 0.44 | 17.6 | |

| อื่น ๆ | |||||

| Electricity | Kilo watt | 30.0 | 0.3 | 9.0 | |

| ค่าใช้จ่ายทั้งหมดของการบำรุงรักษาสภาพเทคโนโลยี | 586.4 | ||||

| Total costs for maintenance of the Technology in USD | 195.47 | ||||

Pellets allow for better storage of fodder and thus less loss of fodder, translating into improved production. Additionally, inputs that cannot be used as fodder directly, can now be processed by the pelletizer into fodder, also improving the production.

Since fodder can be better stored, farmers are better able to overcome failures. Additionally, by using the alternative inputs, feed production is diversified.

Other inputs are used hence production is diversified.

Less cost on commercially produced pellets, and using the comparative advantage of this technology.

The reduced cost translate improved in the increased farm income.

Farmers may sell their own produced pellets, diversifying their income. In addition, farmers are now not solely dependent on their land as they can also use other inputs.

Marginalized farmers have now comparative advantage.

They can produce their own pellets, thus less dependent on imports.

By making use of the by-products there is less pressure of them on the environment.