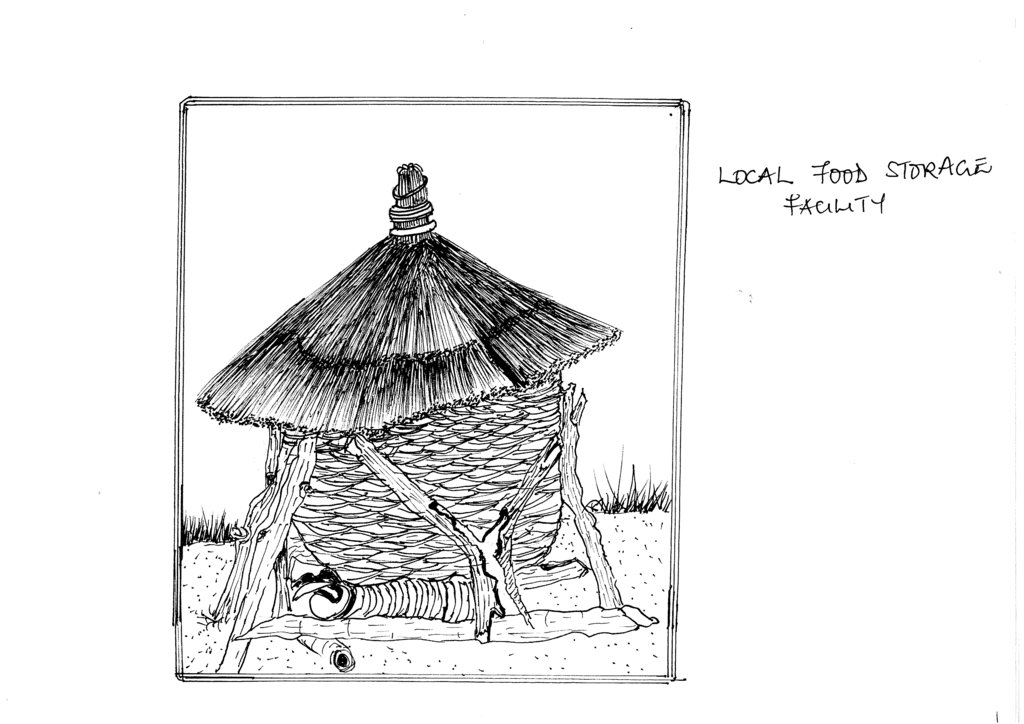

Local Food Storage Facility (Granary) [Uganda]

- Creation:

- Update:

- Compiler: Bernard Fungo

- Editors: JOY TUKAHIRWA, Kamugisha Rick Nelson, betty adoch, Sunday Balla Amale

- Reviewers: Nicole Harari, Udo Höggel

Dero

technologies_2877 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

CDE Centre for Development and Environment (CDE Centre for Development and Environment) - Switzerland1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

12/05/2017

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

The granary is made of local material for food protection/preservation during bumper harvest

2.2 Detailed description of the Technology

Description:

Drought frequencies are increasing while yields are reducing. Efficient post-harvest handling optimizes the value of the produce in climate-affected contexts hence reducing the vulnerability of the farming sector to climate extremes. Granaries are useful structures for preserving grain crops. They help in food storage as a response to climate change impacts.

The main characteristic of the granary is that it is constructed either using a peeled bamboo, papyrus reeds or small sticks of approximately one cm in diameter. Such sticks are usually from Lantana Camara (Common Lantana or Tickberry) or branches of Eucalyptus spp. The material is woven into a round cylindrical shape of about 2 meters height and 1.5 meters in diameter. The structure is then mounted on wooden poles to keep it off the ground to avoid rodents and water from entering. A round roof made of grass is placed on top as a roof to protect the interior of the granary from rain. A space of about 5 cm is left between the roof and the upper end of the round wall in order to allow for aeration. The way of storage in the granary allows air to flow into and out of the granary and reduce / prevent rotting processes due to moisture accumulation in the granary.

The major activity is the construction of the flat granary base structure and later the construction of the superimposed structure using poles on which the granary stands. Periodically the grain is removed and dried in the sun to remove any moisture and pests that may have entered the granary. The granary is also periodically smeared with cow dung to close any holes that develop but also protect it from damage by insects.

What famers like about the technology is that the grain is kept for a long period at the cheapest cost. The materials used to make the granaries are locally available and the skill required in the construction is minimal. Storage space in the house is saved since the granary is established outside.

On the other hand farmers do not like granaries because the food inside them is often prone to theft especially during periods of famine.

2.3 Photos of the Technology

2.4 Videos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Northern

Map

×2.6 Date of implementation

Indicate year of implementation:

1960

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- as part of a traditional system (> 50 years)

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce risk of disasters

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Settlements, infrastructure

- Settlements, buildings

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- rainfed

Number of growing seasons per year:

- 2

Livestock density (if relevant):

N/A

3.4 SLM group to which the Technology belongs

- post-harvest measures

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

Placed within a farm compound

3.6 SLM measures comprising the Technology

structural measures

- S9: Shelters for plants and animals

3.7 Main types of land degradation addressed by the Technology

biological degradation

- Bp: increase of pests/ diseases, loss of predators

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- adapt to land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

The diameter of the granary is about 1.5 meters. The height is about 2 meters.

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

1 Granary

other/ national currency (specify):

Uganda Shillings

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

3500.0

Indicate average wage cost of hired labour per day:

5000

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Cutting and drying sticks and poles | Structural | During the dry season |

| 2. | Making the granary | Structural | During the dry season |

| 3. | Cutting grass | Structural | During the dry season |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Cutting sticks and poles | Mandays | 5.0 | 5000.0 | 25000.0 | 100.0 |

| Labour | Weaving the granary | Mandays | 10.0 | 5000.0 | 50000.0 | 100.0 |

| Labour | Cutting grass | Mandays | 5.0 | 5000.0 | 25000.0 | 100.0 |

| Construction material | Sticks | Sticks | 500.0 | 500.0 | 250000.0 | 100.0 |

| Construction material | Grass | Bundles | 10.0 | 5000.0 | 50000.0 | 100.0 |

| Construction material | Poles | Number | 5.0 | 5000.0 | 25000.0 | 100.0 |

| Total costs for establishment of the Technology | 425000.0 | |||||

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Replacing the grass on top | Structural | Once every three years |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Cutting grass | Mandays | 5.0 | 5000.0 | 25000.0 | 100.0 |

| Construction material | Grass | Bundles | 5.0 | 5000.0 | 25000.0 | 100.0 |

| Construction material | Side poles | Number | 5.0 | 5000.0 | 25000.0 | 100.0 |

| Total costs for maintenance of the Technology | 75000.0 | |||||

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Weaving the granary

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

poor/ none

Water quality (untreated):

poor drinking water (treatment required)

Is water salinity a problem?

No

Is flooding of the area occurring?

Yes

Regularity:

episodically

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- subsistence (self-supply)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

- men

Age of land users:

- middle-aged

- elderly

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Income and costs

expenses on agricultural inputs

Comments/ specify:

Materials are getting more and more scarce due to population growth and land clearing, hence more expensive

farm income

Comments/ specify:

Land is less productive, resulting in poor yields and the need for this technology to reduce post harvest losses

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- 10-50%

If available, quantify (no. of households and/ or area covered):

Approximately 300 households

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 90-100%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Good for storage |

| Cheap |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Fire risk | Keeping away all sources of fire risk, such as ground grass, or cooking near the facility |

| Theft | Make a lockable roof for the granary |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

1

- interviews with land users

1

- interviews with SLM specialists/ experts

3

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules