Mechanized Raised Bed (MRB) Technology in a wheat based production system. [Egypt]

- Creation:

- Update:

- Compiler: Joren Verbist

- Editor: –

- Reviewer: Rima Mekdaschi Studer

technologies_5804 - Egypt

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

Senior Scientist, Irrigation Water Management:

Swelam Atef

International Center of Agriculture Research in the Dry Areas (ICARDA)

Egypt

Social Sciences Specialist (Water Land and Ecosystem Program):

Dessalegn Bezaiet

International Center of Agriculture Research in the Dry Areas (ICARDA)

Jordan

1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Mechanized Raised Beds (MRB)-technology improves livelihoods because raised beds lead to significantly reduced costs (30% less water, 20-40% less nitrogen fertilizer) and higher wheat yields increased by 20-30%. MRB-technology helps to do more with less.

2.2 Detailed description of the Technology

Description:

Mechanized Raised Beds (MRB)-technology has been applied by the International Centre of Agriculture Research in Dryland Areas (ICARDA) and national partners in Egypt. Egypt is a water scarce country and 95% of its water comes from beyond its borders. In addition, Egypt is highly dependent on the import of wheat, 50% of the wheat demand is met by import.

In Egypt, water scarcity and mediocre yield are two issues that keep the majority of people working in the agricultural sector in poverty. Water is scarce as the annual precipitation is less than 250mm leading to most farming to be irrigated. The water comes from the Nile river. However, available irrigation water per farmer is rather low due to population growth. Thus, due to clay soil and the use of flood irrigation, water logging and uneven water distribution over the field lead to salinization of the soil, harming the farmer's yields. Furthermore, the latter is caused by the lack of water, insufficient use of fertilizers and the use of relatively low-quality seeds. In particular, fertilizers are expensive leading to an insufficient and poor application of fertilizers.

In effect, the core objective of MRB-technology package is to fit within this context and realize more output with less input, consequently improving involved livelihoods. Indeed, MRB improves farmers' resilience with increased water and nutrient efficiency. The adopters of MRB receive benefits from direct effects such as improvement in their livelihoods, a decreased workload, increased yields and more efficient use of resources (water, fertilizer and seeds).

The first stage research and designing of MRB-technology was done in 2003. Introductions and pilots of the technology were designed together with regular farmers in the Nile Delta-area, from 2010 until 2013. In 2015, MRB-technology was proven beneficial permitting out-scaling. Thanks to the shown potential of MRB-technology and Egypt's reliance on foreign countries for water and wheat, that MRB-technology has become a strong component of Egypt's national wheat campaign. The Egyptian Government aims to cultivate 2 million acres of wheat under MRB-technology, by 2022.

MRB-technology raises the seedbed simultaneously seeding wheat, consequently creating furrows, of which the length depend on the dimensions of the farm- field. The inter- furrow spacing and the width depends on the type of crop planted and on the soil type. The field/terrain may not exceed a slope of 5%. This allows water to infiltrate, reach the end of the furrow and for safe run-off, preventing water-logging. So, to implement MRB-technology, the field might be levelled prior to implementation, but this is often not the case as MRB is designed to local conditions, and most fields already have a slope of less than 5%. The practice of the machine requires a loose soil, so it is required that the field is ploughed prior to seeding, and therefore MRB is not seen as a type of ploughing. If the field preparation is done, a MRB-machine can start seeding and raising the seedbed. Specific characteristics for MRB-technology with respect to conventional seeding, is that seeding and raising seedbeds are done simultaneously. Raising seedbeds mechanically saves 80% of the workload with respect to manually raising seedbeds. The after-harvest practice depends on the farmer preference, as some farmers prefer letting the stubble grazed, while others clear the field. The after-harvest practices are thus independent with respect to MRB.

In addition, to complement the Mechanized Raised Bed, High Quality Seeds are offered. These are beneficial as they yield higher than the regular wheat seeds. Nevertheless, the machine can also be practiced with regular wheat seeds, if the high-quality seeds are found too expensive by the farmer. The High Quality Sees are hybrid, and need to be replaced after three years to ensure high quality.

The technology has significant positive impacts for local farmers as applied water is saved by 25%, water pumping costs decreased by 25%, seed rate reduced by 50%, farming costs decreased by 30%, fertilizer use efficiency increased by 30%, and crop yield increased by 15-30% with respect to conventional farming. On overall, it is estimated that farming under MRB is about 1/3 of the cost with respect to conventional farming. Manually raising seedbeds was considered too expensive due to the required amount of labour. Thus, regular flood irrigation was practiced. Practically, this results in full surface flooding of the field. This has significantly higher evaporation hence increasing salinization, as opposed to furrow irrigation through raised seedbeds. Also, because water is well distributed over the field due to the furrows (reducing water stress and water logging), there is less leaching of the nutrient hence increased nutrient-efficiency. The raised seedbeds allow excess water, in case of a heavy rainfall event or over-irrigating, to safely run-off. These features of better water disposal and reduced evaporation makes MRB-technology well suited with respect to climate change, which leads to more concentrated rainfall events and increased temperature hence increased evaporation. In addition, as MRB prevents e.g. waterlogging it prevents land degradation (e.g. salinization).

Therefore, livelihoods of farmers who have adopted this technology have been greatly improved. Farmers who have adopted MRB, agree that MRB is affordable, easy to apply, improves production and is cost saving. Furthermore, since this technology increases irrigation efficiency , it can mitigate existing upstream-downstream issues in terms of availability, as there is more available irrigation water. Also, as MRB-technology is currently out scaled, it creates employment opportunities since MRB-machines are locally produced from scratch.

2.3 Photos of the Technology

2.4 Videos of the Technology

Comments, short description:

https://www.youtube.com/watch?v=5SW_Hf5AM3Y

Name of videographer:

ICARDA

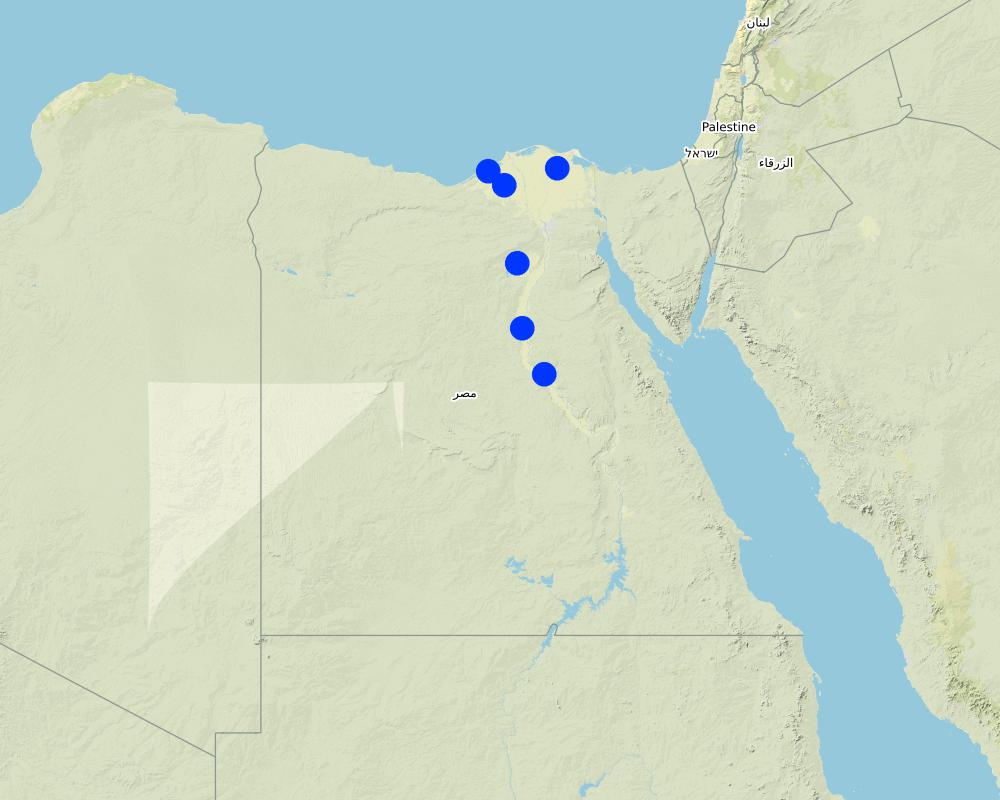

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Egypt

Region/ State/ Province:

Sharkia, Dakahlia, Beheira, Fayoum, Minya and Asuit

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- 1-10 km2

Is/are the technology site(s) located in a permanently protected area?

No

Map

×2.6 Date of implementation

Indicate year of implementation:

2003

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

No

Cropland

- Annual cropping

Annual cropping - Specify crops:

- cereals - wheat (winter)

Number of growing seasons per year:

- 1

Is intercropping practiced?

No

Is crop rotation practiced?

No

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- No (Continue with question 3.4)

3.4 Water supply

Water supply for the land on which the Technology is applied:

- full irrigation

Comments:

The farms are irrigated from water that comes from the Nile river.

3.5 SLM group to which the Technology belongs

- improved plant varieties/ animal breeds

- irrigation management (incl. water supply, drainage)

3.6 SLM measures comprising the Technology

agronomic measures

- A3: Soil surface treatment

- A5: Seed management, improved varieties

structural measures

- S3: Graded ditches, channels, waterways

Comments:

Ploughing is required to allow for raising seedbeds mechanically. Nevertheless, ploughing was also done in conventional farming. As seedbeds are raised whenever wheat is sown, this is recurrent so ploughing is as well.

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cs: salinization/ alkalinization

physical soil deterioration

- Pw: waterlogging

biological degradation

- Bq: quantity/ biomass decline

water degradation

- Ha: aridification

Comments:

Due to degradation the biomass production decrease. MRB-technology increase safe water disposal and decreased evaporation. This results in the prevention of water logging and a decrease in the rate of salinization and aridfication.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Firstly, prior to Mechanized Raised Seedbed (MRB)-implementation the field is prepared. This consist of two-way ploughing. This makes the soil sufficiently loose, to enable the practice of MRB i.e. construction of the raised seedbeds. Also, for successful implementation of the MRB, the field should have a slope of less than 5%.

Secondly, the raised bed seeder is pulled by a tractor and raises the seed bed while seeding wheat, hence Mechanized Raised Seedbed technology. The width of the furrow (A) is 35 -45 cm, this is affected by the related soil texture. The width of the raised seedbed (B) is 100-130 cm, also dependent on the soil texture. Between

seed rows (C) there is a space of 14 cm.This inter-row spacing of the crops relates to the type of crop seeded. The furrow has a depth (D) of 35-45 cm. However, after the first irrigation event the depth could be reduced to 25 cm, due to the influx of loose soil. This is not a problem for the current growing season.

This technical drawing is based on the most common conditions where MRB is implemented. These are that the crop is winter wheat, the soil texture is mostly clay and the system is watered through irrigation coming from the Nile river, rather than rain-fed. If MRB is used under different circumstances, the dimension would change as well.

Lastly, once these above-mentioned steps are successfully done, the agricultural practices do not differ from the previous/traditional method. After harvest, prior to the new season, the raised seedbed structures are still well in shape. This means that after some small reshaping, the raised seedbeds can be used for cultivation again, without using MRB and/or the previously mentioned field preparation. This reshaping is done by cleaning/digging out the furrows. Additionally, this reduces the consequences of compaction by heavy machinery, such as the tractor. As these heavy machinery are used less frequently.

Author:

Joren Verbist (Drawing: Atef Swelam)

Date:

30/09/2020

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

1 acre

If using a local area unit, indicate conversion factor to one hectare (e.g. 1 ha = 2.47 acres): 1 ha =:

2.47 acres

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

6.31

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Purchase MRB |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | MRB-Machine | Machine | 1.0 | 6000.0 | 6000.0 | 100.0 |

| Total costs for establishment of the Technology | 6000.0 | |||||

| Total costs for establishment of the Technology in USD | 6000.0 | |||||

Comments:

The total costs per acre are estimated to be 44 USD to 64 USD for solely a MRB-machine, so the costs of the High Yield Seeds are excluded.

The purchase of a MRB-machine is commonly done by a community (such as a village). Therefore the realistic costs per farmer of the machine are rather low, as well as the cost per area. The tractor which is used to pull a MRB-machine is the same as has been used before the adoption of a MRB, so this is not an additional cost

The High Yield Seeds are offered with a MRB-machine, but a MRB-machine is build that it can use other seeds as well.

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Ploughing | Prior to seeding |

| 2. | Levelling (if needed) | Prior to seeding |

| 3. | Seeding/Raising seedbeds (i.e. use of MRB) | November |

| 4. | Irrigation Event (300-400m3) | Once in every 25-30 days |

| 5. | Fertilizer Application | Establishment Stage (November) |

| 6. | Fertilizer Application | Flowering Stage (March-May) |

| 7. | Fertilizer Application | Grain Filling Stage (June-July) |

| 8. | Harvesting | April |

| 9. | Purchase new High Yield Seeds | Once in the 3 years |

Comments:

MRB-machines are produced by local manufactures. This means that repairs could be done relatively cheap and on time.

The cleaning of the furrows can be done by the farmers self. Therefore, it is not a significant cost.

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Pesticide and herbicide application | Person-Day | 2.0 | 6.0 | 12.0 | 100.0 |

| Labour | Field Preparation and Raising Seedbeds | Person-Day | 2.0 | 100.0 | ||

| Labour | Fertilizer Application | Person-Day | 1.0 | 7.0 | 7.0 | 100.0 |

| Labour | Irrigation Management | Person-Day | 5.0 | 7.0 | 35.0 | 100.0 |

| Equipment | Combine (harvesting) | Machine Day | 1.0 | 64.0 | 64.0 | 100.0 |

| Equipment | MRB | Machine-Day | 1.0 | 10.0 | 10.0 | 100.0 |

| Equipment | Tractor (Raising Seedbed) | Machine-Day | 1.0 | 17.0 | 17.0 | 100.0 |

| Equipment | Sprayer | Machine-Day | 1.0 | 20.0 | 20.0 | 100.0 |

| Equipment | Plough | Machine-Day | 1.0 | 32.0 | 32.0 | 100.0 |

| Equipment | Tractor (Field Preparation) | Machine-Day | 1.0 | 32.0 | 32.0 | 100.0 |

| Plant material | High Yield Seeds | Kilogram | 45.0 | 0.6 | 27.0 | 100.0 |

| Fertilizers and biocides | Fertilizer | Kilogram | 150.0 | 0.26 | 39.0 | 100.0 |

| Fertilizers and biocides | Herbicide | Kilogram | 1.0 | 9.5 | 9.5 | 100.0 |

| Fertilizers and biocides | Pesticide | Kilogram | 2.0 | 7.0 | 14.0 | 100.0 |

| Construction material | Water (Irrigation Event) | 350m^3 | 20.0 | 8.0 | 160.0 | 100.0 |

| Other | Harvesting | Person-Day | 5.0 | 7.0 | 35.0 | 100.0 |

| Other | Maintenance Raised Seedbed | Person-Day | 8.0 | 7.0 | 56.0 | 100.0 |

| Total costs for maintenance of the Technology | 569.5 | |||||

| Total costs for maintenance of the Technology in USD | 569.5 | |||||

Comments:

The pumping cost is 25% less with respect to the conventional flood irrigation.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The most impacting cost factor is the purchase of a MRB-machine. Whereas, the High Yield Seeds are also significant, but the increased yield justifies this. In addition, farmers could also choose to use different seeds. Additionally, the High Yield Seeds are hybrid and can be reproduced for three years on the farm.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

The annual rainfall varies between 20mm and 200mm

Egypt is characterized as a hot desert climate (Köppen climate classification BWh). The hot season is from May to October. While the cool season is opposite, from October to May.

Agro-climatic zone

- semi-arid

- arid

Egypt is characterized as a hot desert climate (Köppen climate classification BWh). The hot season is from May to October. While the cool season is oppesite, from October to May.

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- convex situations

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

- fine/ heavy (clay)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

- fine/ heavy (clay)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

good

Water quality (untreated):

poor drinking water (treatment required)

Water quality refers to:

surface water

Is water salinity a problem?

Yes

Is flooding of the area occurring?

Yes

Regularity:

episodically

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

Individuals or groups:

- groups/ community

Level of mechanization:

- mechanized/ motorized

Gender:

- women

- men

Age of land users:

- middle-aged

- elderly

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

Comments:

However, it is hard to generalize, since the MRB has been used on such a scale, including many different farms and sizes.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- individual

Are land use rights based on a traditional legal system?

Yes

Specify:

Land use right are formed by Islamic influences as well as colonial influences. The are different status such as private ownership and open acces.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

Comments:

In the Nile Delta, the MRB-technology is used on very large area with many different farmers, therefore it is hard to generalize the aspects of the Health and Education since these are highly related to the income of a farm.

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity after SLM:

+20%-30%

Comments/ specify:

The yield is increased due to reduced water stress and because of the use of improved wheat varieties.

crop quality

Comments/ specify:

The quality of the crops is increased due to reduced water stress.

risk of production failure

Comments/ specify:

This decrease as the impact of intense rainfall events is reduced as consequence of safe disposal through furrows.

Water availability and quality

demand for irrigation water

Comments/ specify:

The demand of irrigation water is reduced because the efficiency of it is increased i.e. water is applied more effectively.

Income and costs

expenses on agricultural inputs

Comments/ specify:

50% less seed rate. 20% higher fertilizer efficiency.

farm income

Comments/ specify:

Because of higher yield and less input

workload

Comments/ specify:

The workload was reduced by 80% for mechanized seedbed raising (MRB) compared to manual seedbed raising.

Socio-cultural impacts

conflict mitigation

Comments/ specify:

Because the irrigation efficiency is increased, there is relatively more available irrigation water. This leads to a mitigating effect on upstream/downstream tensions

Ecological impacts

Water cycle/ runoff

surface runoff

Comments/ specify:

Run-off occurs more easily with respect to traditional practices. This is positive, since this prevent water-logging.

excess water drainage

evaporation

Comments/ specify:

Compared to previous border/field irrigation, the water infiltrates easier, and is concentrated more. This leads to a decrease in evaporation.

Soil

soil moisture

nutrient cycling/ recharge

Comments/ specify:

Due to better infiltration, the fertilizers are used more efficient.

salinity

Comments/ specify:

Salinity is decreased because evaporation and water logging is reduced.

Biodiversity: vegetation, animals

biomass/ above ground C

Climate and disaster risk reduction

flood impacts

Comments/ specify:

The impact of a flood is reduced because the excess water is able to safely run-off through the established furrows.

6.2 Off-site impacts the Technology has shown

downstream flooding

Comments/ specify:

Due to the increased irrigation water efficiency, there is relatively more water available to desirably flood (border/surface irrigation/ MRB) farm fields downstream

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | moderately | |

| annual rainfall | decrease | well |

Climate-related extremes (disasters)

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | well |

| flash flood | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

positive

Comments:

In the short-term investments are weighing relatively more than in the long term with respect to the benefits. However, on the overall, the MRB-technology offers more efficient use of resources, coming down to achieving more output with less input. Thus, highly improving the involved livelihoods.

In the long term the benefits are less positive with respect to maintenance. This is due to the aging of machinery. MRB-machines are estimated to have a life span of 12 years.

6.5 Adoption of the Technology

- > 50%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 91-100%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Yes

other (specify):

Local Conditions

Specify adaptation of the Technology (design, material/ species, etc.):

These adaptations are initiated because of the successes of the MRB, so currently MRB-technology is modified to be used with other crops (e.g. Faba Bean), other soil textures and for rain-fed areas.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| MRB significantly contributes to the prosperity of the farmers who have adopted this technology. For farmers, the major advantage of MRB (High Quality Seeds plus the raised seedbeds) is the increased yield. |

| The adoption of the technology leads eventually to less leaching hence higher fertilizer efficiency. This is also highly valued by the farmers as this translates into less expenses. This advantage of the MRB combined to the increased yield, results in the realization of more income with less expenses, and thus a higher net income. |

| In Egypt climate change is visibly present and water does not seem to be abundant anymore, the farmers do have increasingly attention for the value of water. MRB increases the irrigation efficiency, therefore this is also observed as a great advantage of MRB. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The increased yield is of great advantage not only for the improved situation of the involved livelihood, but also on national level. Namely, because more yield means less import of food from other countries. This makes Egypt more self-sufficient, and less dependent on other countries. This is particularly relevant with respect to the significant population growth of Egypt. |

| The increased water availability, because of higher irrigation efficiency is important on a national level. This is certainly important, with respect to trend of increasing the power generation by water (hydraulic power plants), in upstream areas of Egypt. |

| MRB-technology has led to a local industry. This industry is the manufacturing of MRB-machines. This is on broader level beneficial, because it creates local employment, efficient supply chain, easy and fast access to technical knowledge and gives Egypt an independent position. |

| MRB improves soil health because salinization is reduced as water is less evaporated and logged. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| A current risk of MRB is that many farmers are convinced of the beneficial application of the MRB, which means that there is higher demand. Therefore, there is currently not a sufficient number of MRB-machines. In practice this means that some farmers are not able to use MRB-machine during the essential seeding period. This is possibly followed by tensions between users since the technology is often purchased as communities. Land users found this a weakness of the technology. | This is to overcome if public and private sectors invest in the manufacturing of MRB. This would lead to an increased supply of machine, thus eliminating the deficit of machines. |

| The cost of the High Yield Seeds is a weakness of MRB-technology. This is because the costs of the seeds are quite high and they contribute significantly to the increased yields. So without the seeds, MRB-technology does not reach its full potential. Farmers dislike the costs of these seeds and the yearly purchasing. | There are investments needed and plans to improve the production of these seeds. The increased supply would lead to reduced costs. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The risk of tensions that are a consequence of the limited availability of the MRB's. | This could be overcome by increasing the production. However, better social cooperation could reduce the tensions between and within communities as well. |

| The costs of the High Yield Seeds. This is a weakness, because MRB-technology is significantly improved by these seeds, realizing its full potential. | There are investments needed and plans to improve the production of these seeds. This would lead to reduced costs. However, alternatively, other seeds can be used. |

7. References and links

7.1 Methods/ sources of information

- interviews with SLM specialists/ experts

- compilation from reports and other existing documentation

7.2 References to available publications

Title, author, year, ISBN:

Atef Swelam and Y. Atta, (2012) Improve Water Saving and Water Productivity by New Approach of Farm Management under Surface Irrigation. Mi. J. Ag. Eng., 29 (2):745-762.

Available from where? Costs?

https://hdl.handle.net/20.500.11766/12227

7.3 Links to relevant online information

Title/ description:

Jeffrey Alwang, Samy Sabry, Kamel Shideed, Atef Swelam and Habib Halila (2017) Economic and food security benefits associated with raised-bed wheat production in Egypt, Journal of Food Security, FOSE-D-17-00372)

URL:

https://hdl.handle.net/20.500.11766/8228

Title/ description:

Atef Swelam (2016) Science Impact: Raised-bed planting in Egypt: an affordable technology to rationalize water use and enhance water productivity, Issue: 6-FEB 2016, ICARDA.

URL:

https://hdl.handle.net/20.500.11766/5900

Title/ description:

National Wheat Campaign Report (2020), Agricultural Research Center, Ministry of Agriculture and Land Reclamation, Cairo, Egypt

URL:

https://hdl.handle.net/20.500.11766/8228

Title/ description:

Karrou, M., T. Oweis, B. Benli and A. Swelam (2012). Improving Water and Land Productivities in Irrigated Systems, ICARDA, ISBN:92-9127-259-0.

URL:

https://hdl.handle.net/20.500.11766/8825

Title/ description:

Atef Swelam. (16/11/2016). Egypt farmers save water with new irrigation method. New York, United States: The Associated Press (Executive Producer)

URL:

https://hdl.handle.net/20.500.11766/5757

Title/ description:

Atef Swelam. (31/7/2020). On-farm irigation improvement Infographic Map. Beirut, Lebanon: International Center for Agricultural Research in the Dry Areas (ICARDA).

URL:

https://hdl.handle.net/20.500.11766/11823

Title/ description:

Secretariat FAO. (1/4/2018). Mechanized raised-bed irrigation: Production package. Italy: Food and Agriculture Organization of the United Nations (FAO).

URL:

https://hdl.handle.net/20.500.11766/11114

Title/ description:

Swelam, A. ICARDA. (2019, 1 juli). Improve on Farm Irrigation [Presentation]. Slideshare.

URL:

https://hdl.handle.net/20.500.11766/12232

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules