Multi-Nutritional Fodder Blocks for livestock [Niger]

- Creation:

- Update:

- Compiler: Judith Macchi

- Editors: Abdourazak Bawa, Christine Lottje

- Reviewers: Alexandra Gavilano, David Beritault

Lassar Dabbobi

technologies_700 - Niger

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Abdourazak Bawa

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: where people and their land are safer - A Compendium of Good Practices in Disaster Risk Reduction (DRR) (where people and their land are safer)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

HEKS (Hilfswerk der Evangelischen Kirchen Schweiz) (HEKS (Hilfswerk der Evangelischen Kirchen Schweiz)) - Switzerland1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Training and awareness raising in the use of … [Niger]

This approach consists of disseminating improved agricultural techniques to increase the agricultural production. Producers are trained to demonstrate the techniques, and demonstration events are organised to make other producers aware of the use of these improved techniques.

- Compiler: Judith Macchi

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Multi-Nutritional Blocks for livestock are an alternative animal feed for all seasons. They are a concentrate of nutritious elements prepared from crop residues such as stalks, pods, etc.

2.2 Detailed description of the Technology

Description:

Livestock rearing is the second biggest economic activity in Niger after farming. It substantially contributes to food security by providing substantial income to pastoralist households. However, due to the increasing pressure on grazing land because of recurrent drought and proceeding land degradation livestock rearing is becoming more and more difficult, which again accentuates the vulnerability of pastoralist households. The annual fodder balance for livestock, which is depending on the amount of rain, is regularly showing a deficit, thereby weakening the animal food security. Even though the animals consume not more than 30% of dry biomass, the supply is insufficient in most years, hence, the digestible nitrogen intake required for growth and the production of milk, and the requirements of vitamin A and E are not covered. Phosphorus is also an essential element for the metabolism, and must be supplied in sufficient quantity, because the deficiency of these elements in the food intake jeopardizes the survival of the animals. This necessitates to find food supplements which can raise the quality level of the animal feed.

Considering these rather critical and recurrent fodder deficits in Niger, the FAO, in collaboration with the National Agronomic Research Institute of Niger (INRAN), has initiated and tested the technique of the production of multi-nutritional fodder blocks . Agricultural by-products like stalks from millet, sorghum, maize or rice straw are crushed and mixed with micro-nutrients (phosphorus, salt), vitamins and binders (gum arabic, cement), and are compacted in a way that the product can be nibbled by herbivorous animals.

Sahelbio (financed by HEKS/EPER (Swiss Church Aid)) has taken on this technology in a project supporting the food security of rural households by agro-ecological intensification in the department of Mayahi. The production units for the blocks are located in the villages, and are managed by the village committees. The fodder blocks are produced in the form of pyramidal-shaped bricks, or in a form adapted to the needs of the households. The main equipment for producing the bricks includes shredders, mixture containers, molds, scales, and small tools and implements. The blocks are sold locally or at the markets, and thus constitute a source of additional income.

The fodder blocks constitute an alternative for the supplementary feeding of the animals in the period between harvests, or in years with critical fodder deficits. In this way, the blocks enable an increase of the milk and meat production, and the dependency on imported food decreases. Apart from the advantages for the animals, the technology offers the possibility to recover crop residues, while encouraging the population to engage in measures to maintain a vegetation cover (mobile fencing, storage of stalks, weed control, a.s.o.).

2.3 Photos of the Technology

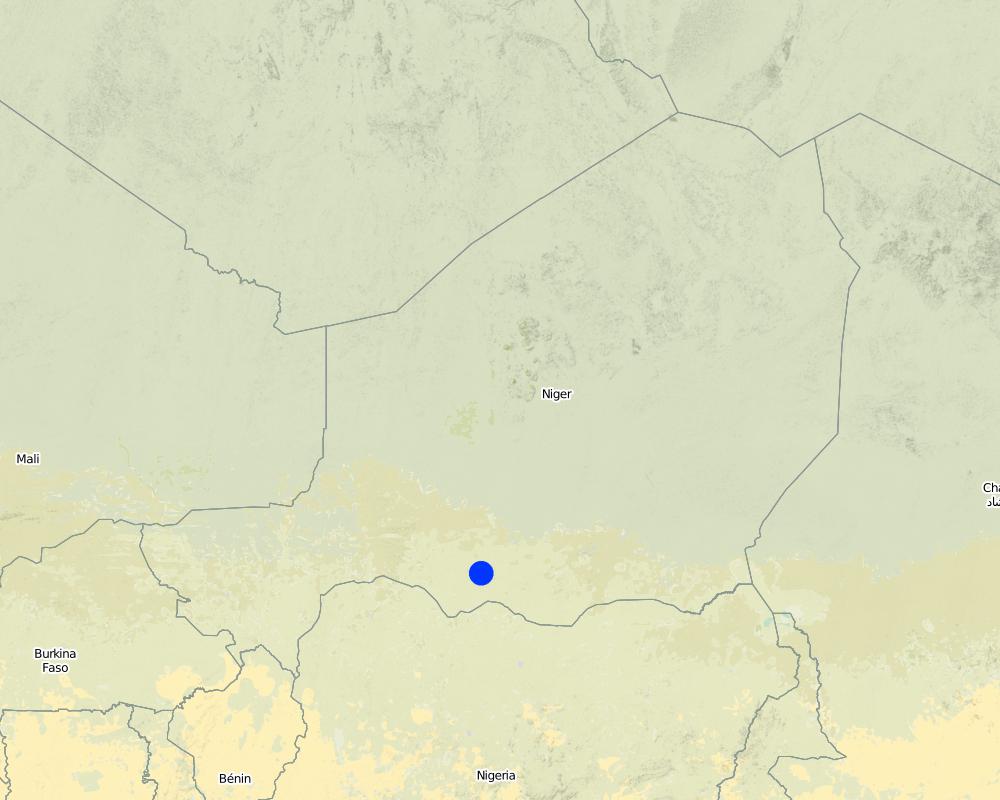

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Niger

Region/ State/ Province:

Maradi

Further specification of location:

Mayahi

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- 10-100 km2

Comments:

The technology is applied in two other villages of the same department.

The technology is intended for livestock farmers, most of whom are pastoralists.

Map

×2.6 Date of implementation

Indicate year of implementation:

2014

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

The technology is introduced by a development project in cooperation with the producers.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

- Mitigate the livestock food crisis and improve the production and productivity of herbivores

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Annual cropping - Specify crops:

- seed crops - sesame, poppy, mustard, other

- oilseed crops - groundnuts

- cereals - millet

- cereals - sorghum

- sorrel

Number of growing seasons per year:

- 1

Grazing land

Extensive grazing:

- Semi-nomadic pastoralism

Intensive grazing/ fodder production:

- Cut-and-carry/ zero grazing

Animal type:

- cattle - non-dairy beef

- goats

- mules and asses

- sheep

Comments:

Main crops (cash and food crops): Millet, sorghum, groundnut, sesame

Main animal species and products: Goats, sheep, cattle, donkeys

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

Comments:

Most of the ingredients (stalks, pods, fruits ...) are harvested after the rainy season.

3.5 SLM group to which the Technology belongs

- pastoralism and grazing land management

- integrated crop-livestock management

- improved plant varieties/ animal breeds

3.6 SLM measures comprising the Technology

vegetative measures

- V3: Clearing of vegetation

other measures

Comments:

This technology enables to recover crop residues while decreasing losses.

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

Comments:

The animals enable that the soil is fertilised with manure.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

Comments:

The technology aims to provide a quality feed to the animals, which contribute in turn to the fertilisation of the soils through manure.

4. Technical specifications, implementation activities, inputs, and costs

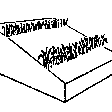

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

The fodder blocks are fed to the animals in a trough in the form of pellets or crushed. The intake capacity of the blocks for grazing animals is 1.5 to 2 kg for the small adult ruminants (goats, sheep) and 7 to 10 kg for adult cattle per day.

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

per 20 kilogram of MNDB

other/ national currency (specify):

CFA franc

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

550.0

Indicate average wage cost of hired labour per day:

1000 CFA francs

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Shredding of stalks | From December to May |

| 2. | Measurement of input quantities | From December to May |

| 3. | Mixing of inputs in a container | From December to May |

| 4. | Moulding of blocks | From December to May |

| 5. | Drying of blocks | From December to May |

| 6. | Sale | From December to May |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Production of blocks | person-days | 4.0 | 1000.0 | 4000.0 | 100.0 |

| Equipment | Shredder | 1.0 | 700.0 | 700.0 | ||

| Equipment | Bucket | 4.0 | 300.0 | 1200.0 | ||

| Equipment | Container | 2.0 | 800.0 | 1600.0 | ||

| Equipment | Mould | 1.0 | 400.0 | 400.0 | ||

| Equipment | Gas-oil | litre | 1.0 | 400.0 | 400.0 | |

| Equipment | Motor oil | litre | 1.0 | 300.0 | 300.0 | |

| Equipment | Mat | piece | 1.0 | 50.0 | 50.0 | |

| Plant material | Stalks of millet or sorghum | kg | 3.0 | 200.0 | 600.0 | 100.0 |

| Plant material | Cowpea tops | kg | 4.0 | 200.0 | 800.0 | 100.0 |

| Plant material | Bran | kg | 4.0 | 200.0 | 800.0 | 100.0 |

| Plant material | Salt | kg | 1.0 | 175.0 | 175.0 | 100.0 |

| Plant material | Acacia pods | kg | 1.0 | 150.0 | 150.0 | 100.0 |

| Plant material | Kalgo pods | kg | 1.0 | 150.0 | 150.0 | 100.0 |

| Plant material | Cement | kg | 1.0 | 125.0 | 125.0 | 100.0 |

| Plant material | Water | litre | 150.0 | 2.0 | 300.0 | 93.0 |

| Total costs for establishment of the Technology | 11750.0 | |||||

| Total costs for establishment of the Technology in USD | 21.36 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

The project has financed the equipment.

Comments:

The costs refer to the manufacturing of 20 kg of fodder blocks.

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Shredding of stalks | From December to May |

| 2. | Measurement of input quantities | From December to May |

| 3. | Making of blocks | From December to May |

| 4. | Mixing of inputs in a container | From December to May |

| 5. | Moulding of blocks | From December to May |

| 6. | Drying of blocks | From December to May |

| 7. | Sale | From December to May |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Production of blocks | person-days | 4.0 | 1000.0 | 4000.0 | 100.0 |

| Equipment | Gas-oil | litre | 1.0 | 400.0 | 400.0 | 100.0 |

| Plant material | Stalks of millet or sorghum | kg | 3.0 | 200.0 | 600.0 | 100.0 |

| Plant material | Cowpea tops | kg | 4.0 | 200.0 | 800.0 | 100.0 |

| Plant material | Bran | kg | 4.0 | 200.0 | 800.0 | 100.0 |

| Plant material | Salt | kg | 1.0 | 175.0 | 175.0 | 100.0 |

| Plant material | Acacia pods | kg | 1.0 | 150.0 | 150.0 | 100.0 |

| Plant material | Kalgo pods | kg | 1.0 | 150.0 | 150.0 | 100.0 |

| Plant material | Cement | kg | 1.0 | 125.0 | 125.0 | 100.0 |

| Plant material | Water | litre | 150.0 | 2.0 | 300.0 | 100.0 |

| Total costs for maintenance of the Technology | 7500.0 | |||||

| Total costs for maintenance of the Technology in USD | 13.64 | |||||

Comments:

The annual cost depends on the production level.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Ingredients, diesel

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

250.00

Specifications/ comments on rainfall:

Rainy season from July to September

Indicate the name of the reference meteorological station considered:

Mayahi

Agro-climatic zone

- semi-arid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Soil texture (> 20 cm below surface):

- coarse/ light (sandy)

Topsoil organic matter:

- low (<1%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

poor/ none

Water quality (untreated):

poor drinking water (treatment required)

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- very poor

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

- men

Age of land users:

- youth

- middle-aged

Indicate other relevant characteristics of the land users:

Predominantly illiterate

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- communal (organized)

Comments:

Access to land is through inheritance, purchase or pawning.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

fodder production

fodder quality

animal production

Income and costs

diversity of income sources

Socio-cultural impacts

food security/ self-sufficiency

SLM/ land degradation knowledge

situation of socially and economically disadvantaged groups

Ecological impacts

Climate and disaster risk reduction

drought impacts

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| seasonal temperature | dry season | increase | very well |

| other gradual climate change | variability of the rainfall (increase of extreme rainfall events, anomalies between the seasons) | increase | very well |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | very well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

6.5 Adoption of the Technology

- 11-50%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

The implementation of the technology requires sizeable assets like shredders, which are not easy to realise in a rural environment where means of subsistence are often lacking.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

Increase of livestock production (breeding, milk, meat...); This technology enables to generate income. |

| The livestock has a higher value; |

| This technology enables to generate income. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Transfer of skills; |

| Tackling food insecurity through the quality of food supply; |

| Improvement of the living standard of the producers. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Sales difficulties, lack of entrepreneurial spirit | Establishment of a marketing mechanism; |

| The large sensitivity of the fodder blocks to fungi | Optimal drying of the products |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Low production | Command of commercial technologies and good coverage of local markets |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

10

- interviews with land users

10

- interviews with SLM specialists/ experts

2

- compilation from reports and other existing documentation

5

When were the data compiled (in the field)?

12/10/2016

7.3 Links to relevant online information

Title/ description:

Boosting agricultural production to prevent food crises

URL:

http://www.fao.org/fileadmin/user_upload/emergencies/docs/Niger_ERCU_Bulletin_1.pdf

Title/ description:

Niger: multi-nutritional densified blocks for livestock

URL:

http://www.waapp-ppaao.org/sites/default/files/fiche_bmn_2.pdf

Title/ description:

THE TECHNOLOGY OF MULTI-NUTRITIONAL BLOCKS IN NIGER

URL:

https://www.youtube.com/watch?v=MH7qfQnFuYE

Links and modules

Expand all Collapse allLinks

Training and awareness raising in the use of … [Niger]

This approach consists of disseminating improved agricultural techniques to increase the agricultural production. Producers are trained to demonstrate the techniques, and demonstration events are organised to make other producers aware of the use of these improved techniques.

- Compiler: Judith Macchi

Modules

No modules