Composting associated with planting pits [Burkina Faso]

- Creation:

- Update:

- Compiler: Moussa Bonzi

- Editor: –

- Reviewers: Fabian Ottiger, Alexandra Gavilano

Zai avec apport de compost (french)

technologies_959 - Burkina Faso

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

De Pury Jean Pascal Etienne

Centre Ecologique Albert Schweitzer (CEAS)

Switzerland

SLM specialist:

Ouedraogo Elisée

Centre Ecologique Albert Schweitzer (CEAS)

Switzerland

SLM specialist:

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: where the land is greener - Case Studies and Analysis of Soil and Water Conservation Initiatives Worldwide (where the land is greener)Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: SLM in Practice - Guidelines and Best Practices for Sub-Saharan Africa (SLM in Practice)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Centre Ecologique Albert Schweitzer (CEAS) - SwitzerlandName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

INERA Institut de l'environnement et de recherches agricoles (INERA Institut de l'environnement et de recherches agricoles) - Burkina Faso1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Zabré women’s agroecological programme [Burkina Faso]

A demand-driven initiative, by a women’s association, aimed at the promotion of composting through training and extension, using project staff and local facilitators.

- Compiler: Unknown User

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Compost production, and its application in planting pits (zai) by farmers on fields near their homes.

2.2 Detailed description of the Technology

Description:

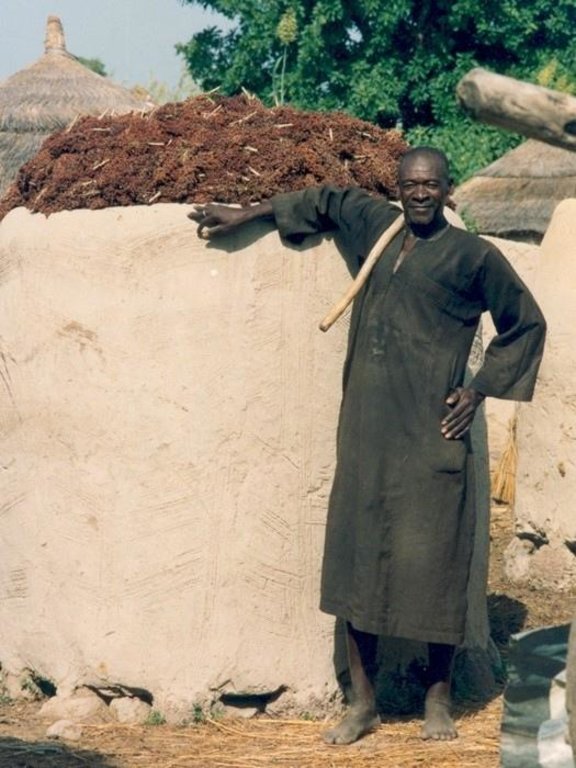

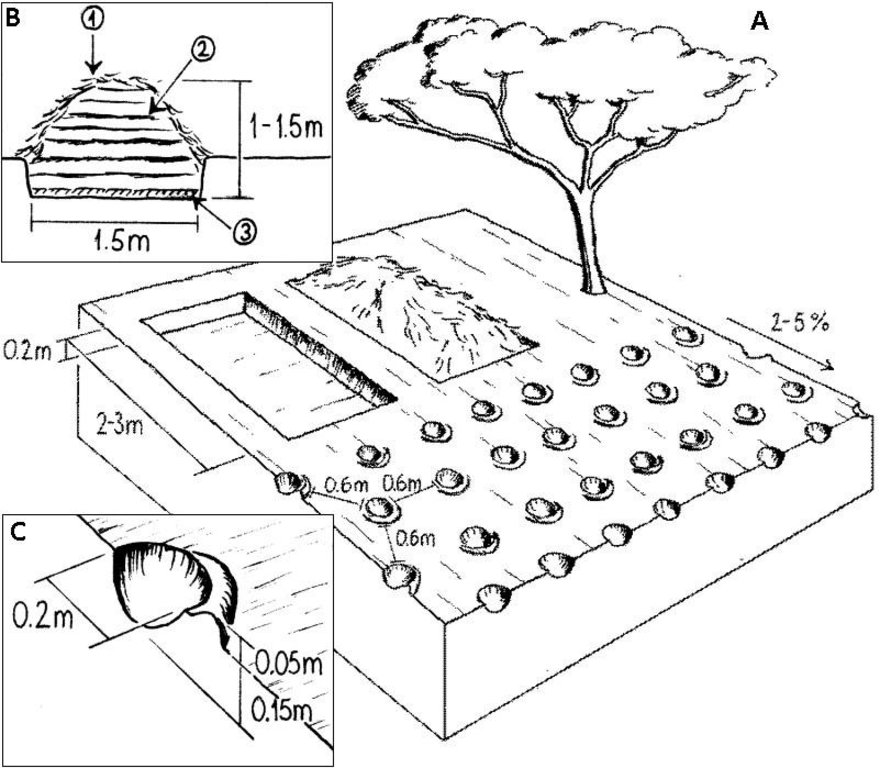

Compost is produced in shallow pits, approximately 20 cm deep and 1.5 m by 3 m wide. During November and December layers of chopped crop residues, animal dung and ash are heaped, as they become available, up to 1.5 m high and watered. The pile is covered with straw and left to heat up and decompose. After around 15-20 days the compost is turned over into a second pile and watered again. This is repeated up to three times - as long as water is available. Compost heaps are usually located close to the homestead. Alternatively, compost can be produced in pits which are up to one metre deep. Organic material is filled to ground level. The pit captures rain water, which makes this method of composting

a valuable option in dry areas.

The compost is either applied immediately to irrigated gardens, or kept in a dry shaded place for the next sorghum seeding. In the latter case one handful of compost is mixed with loose soil in each planting pit (zai). These pits are dug 60 cm by 60 cm apart. Three to four grains of sorghum are planted in each pit. Compost in the pits both conserves water and supplies nutrients. This enables the sorghum plants to establish better, grow faster and reach maturity before the rains finish. As compost is applied locally to the crop, not only is the positive effect maximised, but also the weeds between the pits do not benefit. The water retaining capacity of the compost (absorbing several times its own weight) makes the difference. This is much more important than the additional nutrients, which only become available in subsequent years, and do not anyway completely replace all the nutrients extracted by the crops.

The planting pits also help by harvesting runoff water from the microcatchments between them. Boulgou experiences erratic and variable rainfall with frequent droughts. The poor soils are often crusted and have a low water-retention capacity. Due to a high and increasing population, the land has become exhausted, and fallow periods are no longer sufficient as a consequence. Fertility and yields have declined. Sorghum without compost is more vulnerable to drought and crop failure.

During the dry season, after harvest, fields are grazed by cattle of the nomadic pastoral Peuhl, who also herd the agriculturalists’ livestock. Interestingly, the Peuhl have started to systematically collect the manure for sale, since the increased demand (for composting) has led to doubling of the price. Composting has been applied in Boulgou Province of Burkina Faso since 1988.

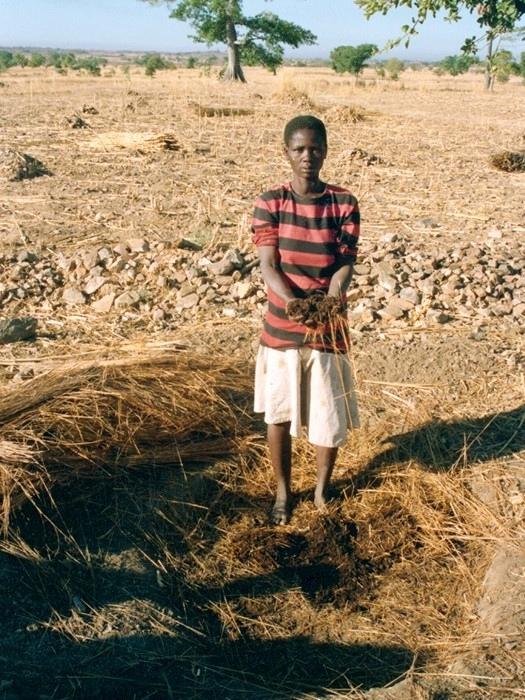

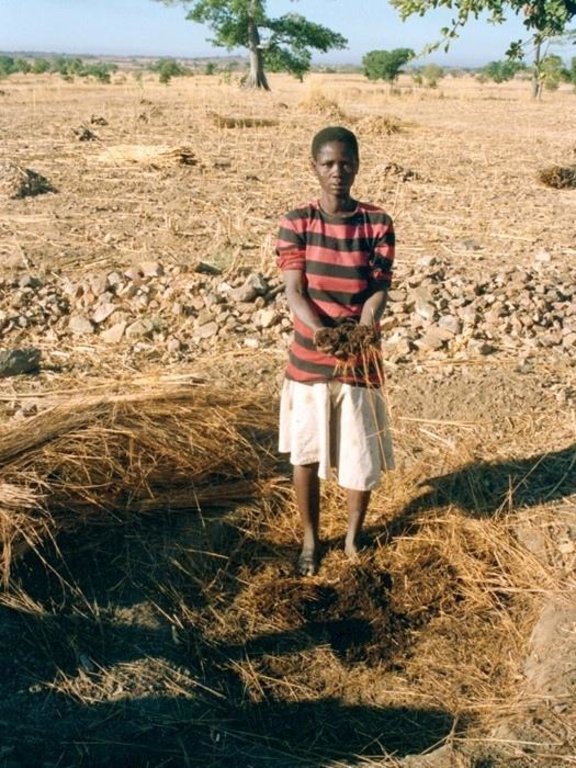

2.3 Photos of the Technology

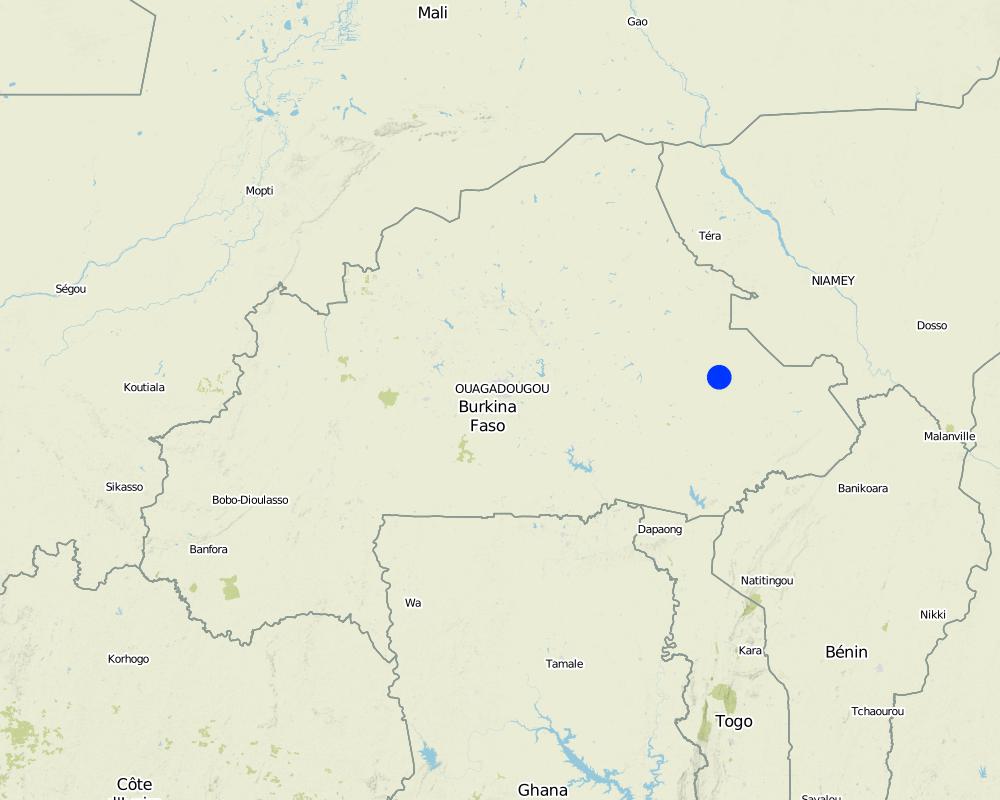

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Burkina Faso

Region/ State/ Province:

Boulgou Province, Burkina Faso

Comments:

Total area covered by the SLM Technology is 200 km2.

Map

×2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

Yes

Specify mixed land use (crops/ grazing/ trees):

- Agro-silvopastoralism

Cropland

- Annual cropping

Annual cropping - Specify crops:

- oilseed crops - groundnuts

- cereals - maize

- cereals - sorghum

- vegetables - leafy vegetables (salads, cabbage, spinach, other)

- vegetables - root vegetables (carrots, onions, beet, other)

- legumes and pulses - peas

Specify:

Longest growing period in days: 180 Longest growing period from month to month: May - Oct

Is crop rotation practiced?

Yes

Grazing land

Animal type:

- goats

- mules and asses

- zebu cattle

Forest/ woodlands

Products and services:

- Fuelwood

- Fruits and nuts

Comments:

Major land use problems (compiler’s opinion): Population increase has led to cultivation of all the available arable land, thus shortening or eliminating fallow periods.

Organic matter in the soil is reduced, the water holding capacity of the soil has diminished and consequently yields have fallen. This has been compounded by the droughts of the 1970s and 1980s. Thirty years ago farmers harvested 800 kg/ha each year, but by the 1980s yields had fallen to merely 400 kg/ha on average.

Main products/ services: Sorghum and zebu cattle (after harvest)

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- improved ground/ vegetation cover

- integrated soil fertility management

- water harvesting

3.6 SLM measures comprising the Technology

agronomic measures

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

physical soil deterioration

- Pc: compaction

- Pk: slaking and crusting

water degradation

- Ha: aridification

Comments:

Main type of degradation addressed: Wt: loss of topsoil / surface erosion, Cn: fertility decline and reduced organic matter content, Pc: compaction, Pk: sealing and crusting, Ha: aridification

Main causes of degradation: over-exploitation of vegetation for domestic use, other human induced causes (specify) (causes agricoles: Suppression des jachères; surpâturage), other natural causes (avalanches, volcanic eruptions, mud flows, highly susceptible natural resources, extreme topography, etc.) specify (Secheresse du sol due à la destruction de l'humus plus qu'aumanque de pluie.), Expansion démographique, manque de connaissances (Comment acquerir ces connaissances)

Secondary causes of degradation: deforestation / removal of natural vegetation (incl. forest fires), manque de moyens financiers (comment en produire avec des connaissances)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

A: Overview of compost making and zai planting pits within a field. Tree shade helps to conserve moisture in the compost pits.

B: Cross section of compost pit: protective straw (1); successive layers of compost (2), clay layer at the bottom (3).

C: Detailed view of zai planting pit.

Technical knowledge required for field staff / advisors: low

Technical knowledge required for land users: moderate

Main technical functions: increase / maintain water stored in soil

Secondary technical functions: increase in organic matter, increase of infiltration, increase in soil fertility, improvement of soil structure

Manure / compost / residues

Material/ species: compost

Quantity/ density: 7-10 t/ha

Remarks: applied in planting pits

Author:

Mats Gurtner

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Transport compost to the fields: | April / annual |

| 2. | Deepen planting pits (zai) (to original dimensions of 15 cm deep, 20 cm diameter, and 60 cm apart) and apply a handful of compost mixed with earth, just before planting sorghum | After the first rains / annual |

Comments:

Editors’ comments: Soil fertility decline is a major problem for much of Africa, and composting provides an opportunity for local mitigation of this. There are many ways of making compost, and this case is a good example of ‘aerobic heap compost’ from Burkina Faso. Here, the compost is concentrated in planting pits, which additionally harvest water.

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 2.0 | 2.0 | 100.0 |

| Equipment | Tools | ha | 1.0 | 10.0 | 10.0 | 100.0 |

| Construction material | Clay | 1 | ||||

| Total costs for establishment of the Technology | 12.0 | |||||

| Total costs for establishment of the Technology in USD | 12.0 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Dig two compost pits (3 m by 1.5 m and 20 cm deep). Cover the bottom of each pit with 3 cm clay layer. | beginning of the dry season (November). / initial establishment |

| 2. | Put 20 cm layer of chopped crop residues (cereal straw) into thecompost pit (water with one bucket). Add 5 cm layer of animal manure. Add 1 cm layer of ash. Repeat steps 1–3 until the compost pile is 1.0–1.5 m high. | November / annual |

| 3. | Cover pile with straw to reduce evaporation, and leave to decompose. | November / annual / up to 3 times (as long as water is available) |

| 4. | Turn compost after 15 days into the 2nd pit, then after another 15 days back into the 1st pit. Water the pile after each turning with 3 buckets of water. | / up to 3 times (as long as water is available) |

| 5. | Store ready compost in dry shady place. | January / annual |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 20.0 | 20.0 | 100.0 |

| Equipment | Wheelbarrow renting | ha | 1.0 | 6.0 | 6.0 | 100.0 |

| Equipment | None | None | 1.0 | |||

| Equipment | None | None | 1.0 | |||

| Fertilizers and biocides | Compost/manure | ha | 1.0 | 2.0 | 2.0 | 100.0 |

| Construction material | Wet straw | ha | ||||

| Construction material | ash | ha | ||||

| Other | Compost transportation | ha | 1.0 | 2.0 | 2.0 | 100.0 |

| Total costs for maintenance of the Technology | 30.0 | |||||

| Total costs for maintenance of the Technology in USD | 30.0 | |||||

Comments:

Machinery/ tools: hoe, knife, digging stick, bucket

Costs relate to production and application of one ton of compost per hectare - which a farmer can make in one year and is the product of one full compost pit. The compost is directly applied to each planting pit: since the pits all in all

constitute only around 10-15% of the field surface, compost is effectively applied at a concentration of 7-10 t/ha. This rate is equal to actual rates applied in small irrigated gardens (<0.1 ha). If compost is produced in deep pits, production is cheaper because there is less work involved.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Duration of establishment: 1 week

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

- fine/ heavy (clay)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil texture: Fine / heavy (elevations) and coarse/light (depressions)

Soil fertility: Low (ranked 1) and medium (ranked 2)

Topsoil organic matter: Low (and decreasing further)

Soil drainage/infiltration: Poor (ranked 1) and medium (ranked 2)

Soil water storage capacity: Low

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

- mixed (subsistence/ commercial)

Off-farm income:

- less than 10% of all income

Level of mechanization:

- manual work

- animal traction

Indicate other relevant characteristics of the land users:

Market orientation: Subsistence (ranked 1) and mixed (ranked 2, in good years)

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Comments:

Average area of land owned or leased by land users applying the Technology: 0.5-1 ha, 1-2 ha, 2-5 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

Land use rights:

- communal (organized)

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

fodder production

fodder quality

Income and costs

farm income

Comments/ specify:

By several times in dry years, compared to no compost use

workload

Other socio-economic impacts

Integration of agriculturalists and pastoralists

Input constraints

Comments/ specify:

Water for compost making

Socio-cultural impacts

community institutions

conflict mitigation

Ecological impacts

Water cycle/ runoff

excess water drainage

Soil

soil moisture

soil cover

soil loss

Other ecological impacts

Soil fertility

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

If available, quantify (no. of households and/ or area covered):

5000

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 91-100%

Comments:

100% of land user families have adopted the Technology without any external material support

There is a strong trend towards spontaneous adoption of the Technology

Comments on adoption trend: Strong trend towards growing spontaneous adoption. Almost everybody wants to imitate neighbors - but not everyone had received adequate training. Demand grew because of the expanded membership of the association. Some pastoralists use it in their gardens.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

All land users, even the poorest, can learn to make and apply compost. No jealousy amongst land users, which is a prerequisite for ist spread/acceptance How can they be sustained / enhanced? Keep going with training and extension. |

|

Possibility of doubling cereal yields in normal years: any surplus production can be sold How can they be sustained / enhanced? Produce enough good compost/manure. |

| Ensures yields in dry years, giving security against drought and hunger. |

|

Gives high income in dry years due to production increase and double prices on the market for the surplus How can they be sustained / enhanced? However the government is attempting to stabilise prices, so this benefit might not endure. |

| Requires only locally available resources, and knowledge about compost application is ‘owned’ by the farmers: nobody can take it away from them. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The modest quantity of compost applied is not enough to replace the nutrients extracted by the crops in the long term | Small amounts of nitrogen and phosphorous fertiliser need to be added and crop rotation practiced. |

| The short/medium term local benefits are not associated with a positive overall, long-term ecological impact because there is a net transfer of organic matter (manure) to the fields from the surroundings | Improve management of the vegetation outside the cropland, avoiding overgrazing etc to increase manure production. |

| Needs considerable water and thus also extra labour | Pit composting helps to reduce water requirement in drier areas and at the same time reduces labour input. |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

Ouedraogo E . Influence d’un amendement de compost sur sol ferrugineux tropicaux en milieu paysan. Impact sur laproduction de sorgho à Zabré en 1992. Mémoire de diplôme.. 1992.

Available from where? Costs?

CEAS Neuchâtel, Switzerland

Title, author, year, ISBN:

Zougmore R, Bonzi M, et Zida Z . Etalonnagedes unités locales de mesures pour le compostage en fosse de type unique étanche durable. Fiche technique de quantification des matériaux decompostage, 4pp. 2000.

Title, author, year, ISBN:

Zougmore R, Bonzi M, et Zida Z . Etalonnagedes unités locales de mesures pour le compostage en fosse de type unique étanche durable. Fiche technique de quantification des matériaux decompostage, 4pp. 2000.

Title, author, year, ISBN:

Zougmore R, Bonzi M, et Zida Z . Etalonnagedes unités locales de mesures pour le compostage en fosse de type unique étanche durable. Fiche technique de quantification des matériaux decompostage, 4pp. 2000.

Title, author, year, ISBN:

Zougmore R, Bonzi M, et Zida Z . Etalonnagedes unités locales de mesures pour le compostage en fosse de type unique étanche durable. Fiche technique de quantification des matériaux decompostage, 4pp. 2000.

Title, author, year, ISBN:

Zougmore R, Bonzi M, et Zida Z . Etalonnagedes unités locales de mesures pour le compostage en fosse de type unique étanche durable. Fiche technique de quantification des matériaux decompostage, 4pp. 2000.

Links and modules

Expand all Collapse allLinks

Zabré women’s agroecological programme [Burkina Faso]

A demand-driven initiative, by a women’s association, aimed at the promotion of composting through training and extension, using project staff and local facilitators.

- Compiler: Unknown User

Modules

No modules