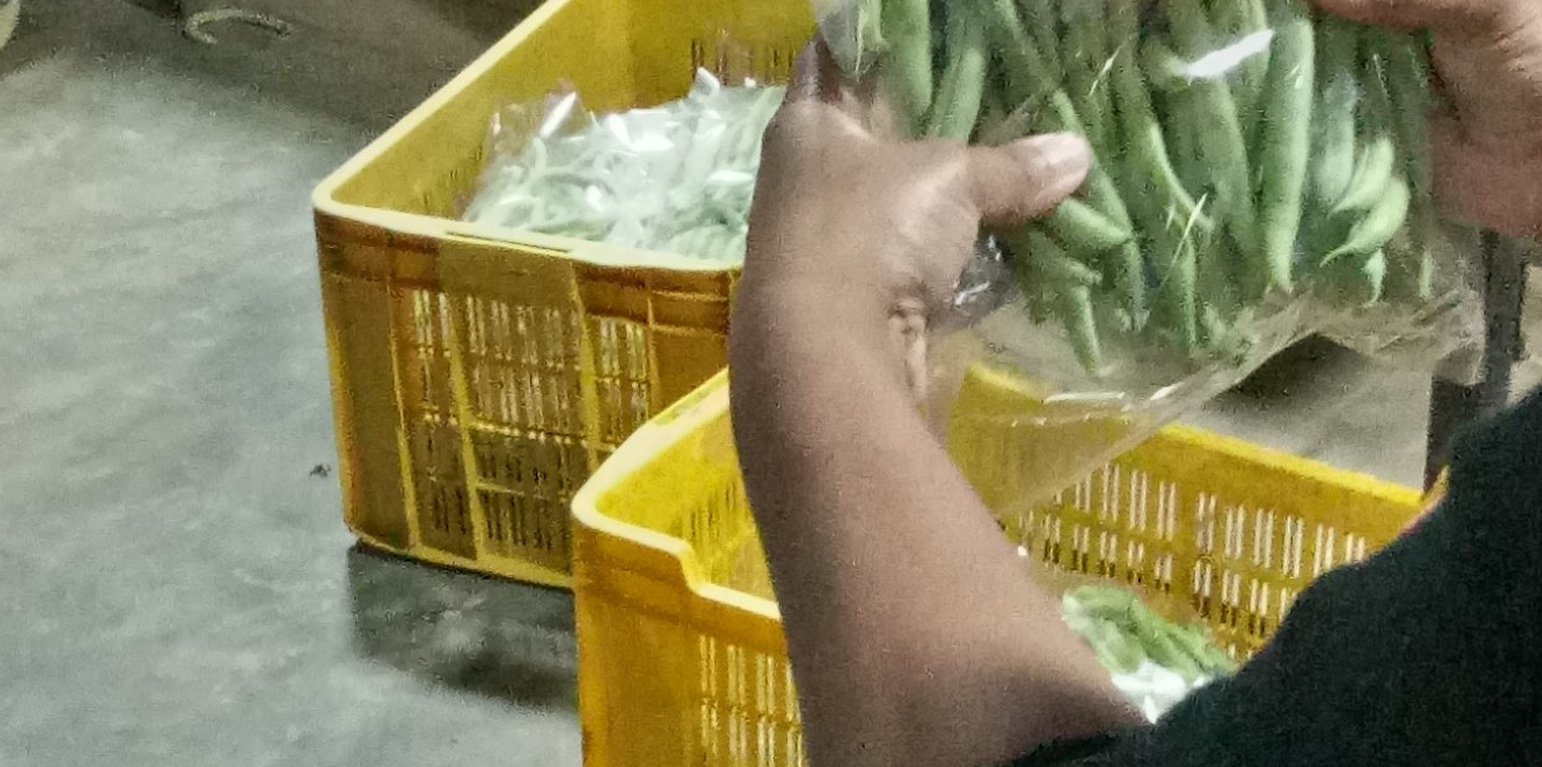

This approach was implemented in vegetable growing lands in hilly and rolling terrain, where the average annual rainfall is relatively high: Wet zone (>2500 mm) Intermediate zone (1750-2500 mm-short dry periods). Controlling soil erosion is crucial in these regions. Further, overuse and misuse of agrochemicals are common among the farmers. On the other hand, farmers experience lack of market opportunities, lack of technical and financial support and water scarcity in the intermediate zone which restricts farming to 1 or 2 cropping cycles. This approach aims to support vegetable growers by providing financial and technical support to implement technologies to minimize soil erosion and increase fertilizer and water use efficiencies, while providing adequate market opportunities and product value addition.

In the field, the following technologies were implemented as a package: plastic mulch, terracing, drip irrigation systems, fertigation units and insect proof nets. Furthermore, capacity development programs were implemented along with continuous monitoring, financial support was provided to adopt the technologies. The market opportunity was expanded via value addition through “GAP-certification" (GAP = Good Agricultural Practices) and facilitating easy and secured access to market via private sector involvement.

By adopting this technological package farmers were able to reduce the fertilizer use by about 70-80 % via "fertigation" - that is fertilizer mixed in irrigation water. Further, the pest attacks and need of insecticides were significantly reduced due to insect proof nets. The weed growth was negligible due to the plastic mulch which reduced the labour cost significantly as previously, farmers used to control weeds manually. Soil erosion was minimal due to plastic mulch used over the contour terraces. The water use efficiency was improved via drip irrigation and the farming was not affected by the short drought periods. The overall cost reduction that the farmers experience by adopting this technological package was about 20%. Further, the yield increase was about 20%, which raised the profit by 30%. Proper use of pesticides with adequate safety measures and safe disposal of the pesticide containers are mandatory to be qualified for GAP-certification. Farmers that adopt this approach collect pesticide containers in a designated place in the farm.

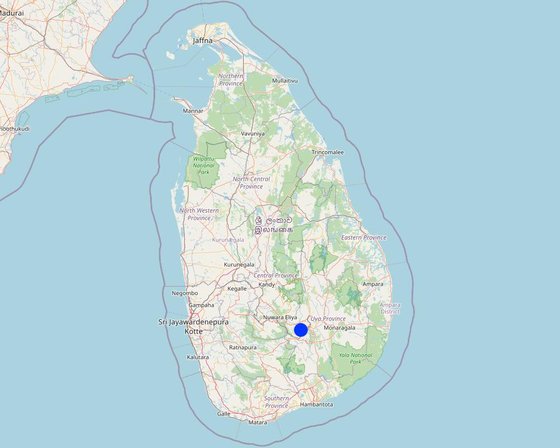

The implementation of the approach was as follows:

1.Discussions between Food and Agriculture Organization of United Nations (FAO) and Department of Agriculture, Sri Lanka (DOA) to develop a private-public partnership (PPP).

2.Call for proposals from private sector supermarket owners and exporters.

3.The proposal of Cargills (Ceylon) PLC was accepted.

4.Areas with easy access to Cargill’s vegetable collection centers were selected for the pilot programme, namely Haguranketha and Nuwarleiya, Boralanda and Bandarawela.

5.Eighty progressive farmers who had been providing vegetables for the already established vegetable collection centers were selected for the initial program.

6.Farmer awareness programs and Farmer Field Schools were conducted on the technological package, the GAP certification process and market arrangements.

7.The technical package was installed in farmers’ fields. Farmers were supported financially to obtain raw materials and cover the capital cost (for polythene, drip irrigation systems, insect-proof nets and accessories, fertilizers and pesticides). The cost estimated to implement the package was Rs. 300,000 for quarter of an acre (Rs. 2.96 million/ha = approx. UD$ 8950/ha). Cargills and the FAO funded RDAL (Rehabilitation of degraded agricultural lands in the central highlands of Sri Lanka) shared 2/3 of the material cost. The rest of the cost was borne by the farmer. Cargills Bank provided low interest loans to farmers to cover their share of the capital cost.

8.Continuous monitoring and capacity development and motivational programs were implemented via field visits and WhatsApp groups.

9.GAP-certification was provided for the vegetables.

10.A market was provided by Cargills with a guaranteed 10% premium above the standard rate.

11.Alongside the implementation processes, other developments took place. These included: supply of fertilizers and pesticides to farmers and provision of study scholarships for children of the farmers by Cargills.

The limitations of the approach are as follows: first, reluctance of the farmers to follow the rigorous record-keeping process necessary to obtain the GAP-certification; second, the absence of a proper methodology to recycle or upcycle the pesticide containers; third, the on-going lack of consumer awareness about the GAP-certified products.

地点: Ambegoda Village, Bandarawela/Badulla District/Uva Province, 斯里兰卡

启动日期: 2019

终止年份: 不适用

方法的类型

| 该方法涉及哪些利益相关者/执行机构? | 指定利益相关者 | 说明利益相关者的角色 |

| 当地土地使用者/当地社区 | Farmers | Farmers implement the technology in their fields |

| SLM专家/农业顾问 | Agricultural Instructors (AI) of DOA | AIs organize farmer field schools and training programmes for farmers. They also visit the fields to guide, monitor and provide recommendations for the farmers for successful implementation of the approach. The experts connect with the farmers through WhatsApp groups, where the farmers can quickly find solutions for the issues. Also, it facilitated the peer learning among the farmers. |

| 私营部门 | Cargills (Ceylon) PLC | Cargills (Ceylon) PLC is the buyer of the fresh produce from farmers who practice this approach. The collection centre manager of the Cargills (Ceylon) PLC plays a critical role. He connects with the farmers from the field establishment of the technology package to packing and transporting the final produce to the collection centers. |

| 国际组织 | FAO | FAO initiated the program and is one of the main coordinating bodies of the project of Rehabilitation of degraded agricultural lands in the central highlands of Sri Lanka (RDAL). |

The flow chart demonstrates the approach with the intervening steps of the Public and private sectors

决策是由......做出的

决策是基于

Establishment and maintenance of GAP technology in farmer fields, irrigation management (drip irrigation), pests and disease management, fertilizer application through drip irrigation (fertigation), post-harvest technology, nursery management

Drip irrigation system (pipes, nozzles, pumps, filters, water tank) Insect proof net Plastic materials for the mulch

土地使用者的劳动力为

If yes, specify: Cargills (Ceylon) PLC prioritize the project farmers when purchasing the produce at collection centres and also they provide packing and branding materials under Cargill’s Good Harvest Brand. A 20% extra payment, above the normal purchasing price, is made for GAP-Certified, ‘Good Harvest’ branded products, subject to a minimum and maximum amounts of Rs. 10.00 and Rs. 30.00 per kg respectively.

The stakeholder’s participation is encouraged through farmer field schools and advisory services. The collective action of farmers to solve field problems themselves is observed through such programs.

The technology package introduced for farmers, insect proof net, drip irrigation system and plastic mulch, through the approach aims for irrigation water conservation; mitigate soil erosion and pest and disease attacks.

The technology package of the approach is ultimately reducing the cost for labour, irrigation, pesticides and other agrochemicals.

Farmers receiving a loan to implement the approach in their fields.

The farmers were trained on SLM practices through extension programs (farmer field schools and advisory services).

Active involvement of public and private sector participation is a distinct feature of the approach

The interest on participation of young generation in the approach is significant due to implementation of novel technologies. And also because of the deviation of the traditional vegetable cultivation practices.

The approach helps to improve the yield and the quality of the produce

The harvest of the farmers who implement the technologies, is purchased by the Cargills (Ceylon) PLC for a reasonably higher price.

Farmers require less irrigation water when cultivating under drip irrigation and plastic mulch technologies. Hence the cultivation can proceed even under a drought or water scarce conditions.

The assurance of the market for value added products via well-established market chain of the Cargills (Ceylon) PLC is a major reason behind the sustainability of the approach.