Central Asia is known for its harsh climate, extreme temperature differences and low precipitation. Uzbekistan is no exception to this. Its temperatures vary between -20 and 40 degrees Celsius and precipitation is limited to less than 400 millimetres. This results in difficult conditions for farmers to ensure agricultural production and food security.

Winter wheat is commonly grown to achieve food security and farm income as it is suited to the environment. However, the continuous cultivation of winter wheat has led to severe soil degradation and depletion, through extraction of soil organic matter and soil nutrients. Inevitably, this makes the soil unsuitable for crop cultivation.

The International Centre of Agricultural Research in Dry Areas (ICARDA) anticipated this challenge, and introduced improved mung bean varieties in 2014. Mung bean (or "green gram": Vigna radiata) is a leguminous crop, which replenishes soil organic matter and fertility through nitrogen fixation. By including mung bean in the winter wheat production system, soil health is improved, fallow period reduced, and farmer incomes are increased. The increased farm income is due to the reduced amount of fertilizer required, increased yields and higher selling prices.

Mung bean realizes a profit of roughly 2000 USD per hectare in a period of 100 days, while winter wheat profits are approximately 600 USD per hectare in an eight month period. These numbers show the significant benefit of incorporating mung bean. Scientist have demonstrated that cultivating only mung bean would lead to even higher profit margins, but concluded that adoption is unrealistic as wheat is pre-dominantly grown for food security.

The incorporation of mung bean in the agricultural production system has one downside and that is increased irrigation demand, because mung bean requires additional water.

The mung bean-winter wheat-system follows the following crop rotation. The field for mung bean is tilled and harrowed, prior to seeding. Mung bean is mechanically seeded and manually harvested in June-July and September-October respectively. In this growing period, the field is weeded either manually or by a cultivator, irrigated, fertilizer mechanically applied or hand broadcast and mechanically weeded.

Winter wheat is mechanically planted in October, after the field is harrowed. In March-April, the wheat crops are treated with chemicals and fertilizers. In June-July, the winter wheat is mechanically harvested. Winter wheat also receives irrigation through a canal.

To conclude, this documentation shows that smart ICARDA crop choice with improved varieties extremely benefits local farmers incomes and adds resilience. It also reduces land degradation within a commonly used production system.

Data presented in this work is partly made available through CGIAR Research Program on Dryland Systems; Collaborative Research Project on Sustainable Soil Management to Enhance Agricultural Productivity in Central Asia funded by IFPRI within the framework of Russian Federation funding to CGIAR (2018-2019); CGIAR Collaborative Research & Capacity Building Program for the Development of Sustainable and Resilient Agricultural Production in Central Asia within the framework of Russian Federation Funding (2013-2016).

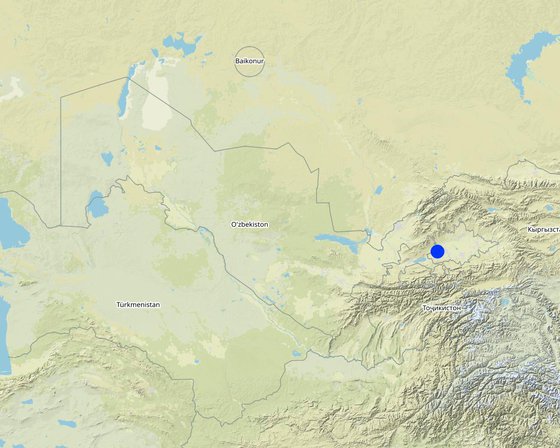

Location: Uzbekistan

No. of Technology sites analysed: 100-1000 sites

Spread of the Technology: evenly spread over an area (approx. 10-100 km2)

In a permanently protected area?: Nee

Date of implementation: less than 10 years ago (recently)

Type of introduction

| Specify input | Unit | Quantity | Costs per Unit (USD) | Total costs per input (USD) | % of costs borne by land users |

| Labour | |||||

| WW: Irrigating | Person-days | 6.0 | 10.0 | 60.0 | 100.0 |

| MB: Weeding | Person-days | 3.8 | 10.0 | 38.0 | 100.0 |

| MB: Harvesting | Person-days | 3.8 | 10.0 | 38.0 | 100.0 |

| MB: Irrigating | Person-days | 2.0 | 10.0 | 20.0 | 100.0 |

| Equipment | |||||

| MB: Plowing | Machine-Hours | 1.0 | 25.0 | 25.0 | 100.0 |

| MB: Tilling & Harrowing | Machine-Hours | 1.0 | 16.0 | 16.0 | 100.0 |

| MB: Seeding | Machine-Hours | 1.0 | 20.0 | 20.0 | 100.0 |

| MB: Cultivation | Machine-Hours | 3.0 | 15.0 | 45.0 | 100.0 |

| WW: Levelling | Machine-Hours | 1.0 | 25.0 | 25.0 | 100.0 |

| WW: Seeding | Machine-Hours | 2.0 | 15.0 | 30.0 | 100.0 |

| WW: Chemical Spray | Machine-Hours | 3.0 | 5.0 | 15.0 | 100.0 |

| WW: Fertilizer Application | Machine-Hours | 4.0 | 5.0 | 20.0 | 100.0 |

| Plant material | |||||

| MB: Seeds | Kilogram | 18.0 | 2.2 | 39.6 | 100.0 |

| WW: Seeds | Kilogram | 250.0 | 0.45 | 112.5 | 100.0 |

| Fertilizers and biocides | |||||

| MB: Amophos | Kilogram | 200.0 | 0.24 | 48.0 | 100.0 |

| MB: Urea | Kilogram | 150.0 | 0.23 | 34.5 | 100.0 |

| WW: Amophos | Kilogram | 300.0 | 0.24 | 72.0 | 100.0 |

| WW: Urea | Kilogram | 700.0 | 0.23 | 161.0 | 100.0 |

| WW: Herbicide | Gram | 300.0 | 0.17 | 51.0 | 100.0 |

| WW: Fungicide | Milliliter | 200.0 | 0.035 | 7.0 | 100.0 |

| WW: Pesticide | Milliliter | 200.0 | 0.015 | 3.0 | 100.0 |

| Other | |||||

| WW: Threshing | Machine-Hours | 1.0 | 50.0 | 50.0 | 100.0 |

| MB: Threshing | Machine-Hours | 2.0 | 35.0 | 70.0 | 100.0 |

| MB: Cleaning | Machine-Hours | 1.0 | 25.0 | 25.0 | 100.0 |

| Total Fuel Required | Liter | 115.0 | 0.85 | 97.75 | 100.0 |

| Total costs for establishment of the Technology | 1'123.35 | ||||

| Total costs for establishment of the Technology in USD | 1'123.35 | ||||