Rubagano rooftop rainwater harvesting system (with concrete/brick tank) [Uganda]

- Creation:

- Update:

- Compiler: Wilson Bamwerinde

- Editor: –

- Reviewers: Fabian Ottiger, Alexandra Gavilano

Okwombeka tanka z'amaizi ahamaju (Runyankore)

technologies_1595 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

SLM specialist:

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

The Transboundary Agro-ecosystem Management Project for the Kagera River Basin (GEF-FAO / Kagera TAMP )Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Food and Agriculture Organization of the United Nations (FAO) - Italy1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Rain-water from all corrugated iron roof structures in one compound is harvested and stored in underground tanks.

2.2 Detailed description of the Technology

Description:

Despite high precipitation (>1200 mm), Rubagano still experiences water shortage. It is hilly, with steep (>30%) to very steep (>58%) slopes. Rain water runs off to the valleys below, causing erosion and damaging infrastructure such as roads along its course. There is little rain water infiltration and the ground water level low. The few boreholes that government constructed in the area are often dry. Therefore women and children normally walk distances of up to 4 km to fetch water which, in many cases, is actually runoff dammed behind a concrete wall built across an open rock patch. To alleviate water scarcity, farmers have been mobilized by Kagera TAMP project to harvest the rain water from their own roofs. Because water sources are far from most households, rooftop water harvesting has a very high utility for the farmers. Adoption is high.

Purpose of the Technology: The primary goal of the technology is to increase household water availability. It also reduces runoff, produces water for the tree nursery and backyard gardens..

Establishment / maintenance activities and inputs: Requirements for harvesting water on an iron roof are water collection gutters and an underground tank. Rain falling on the roof flows into collection gutters constructed around the roof which angle gently away from the house and end at one or more underground tanks. Excavation and construction of the storage tank is costly and requires well qualified artisans. These are trained locally and are available within the community to minimize costs. The underground tank is constructed by excavating the ground between 3.0 m and 3.5 m deep and 2.0 m to 2.5 m diameter. Thus, a small tank will have a capacity of 38,000 litres (38 cubic metres). The bottom and walls of the pit is then built up throughout with brick and mortar. The top is a concrete slab with 2 openings of 0.3 m diameter, one connected to the gutters and the other through which a plastic container is lowered to fetch water. Though establishment costs appear high for farmers, the longer term benefits outweigh the original cost. Once established the maintenance costs are limited to periodic cleaning.

Natural / human environment: Heavy rainstorms may blow the gutters out of position.

2.3 Photos of the Technology

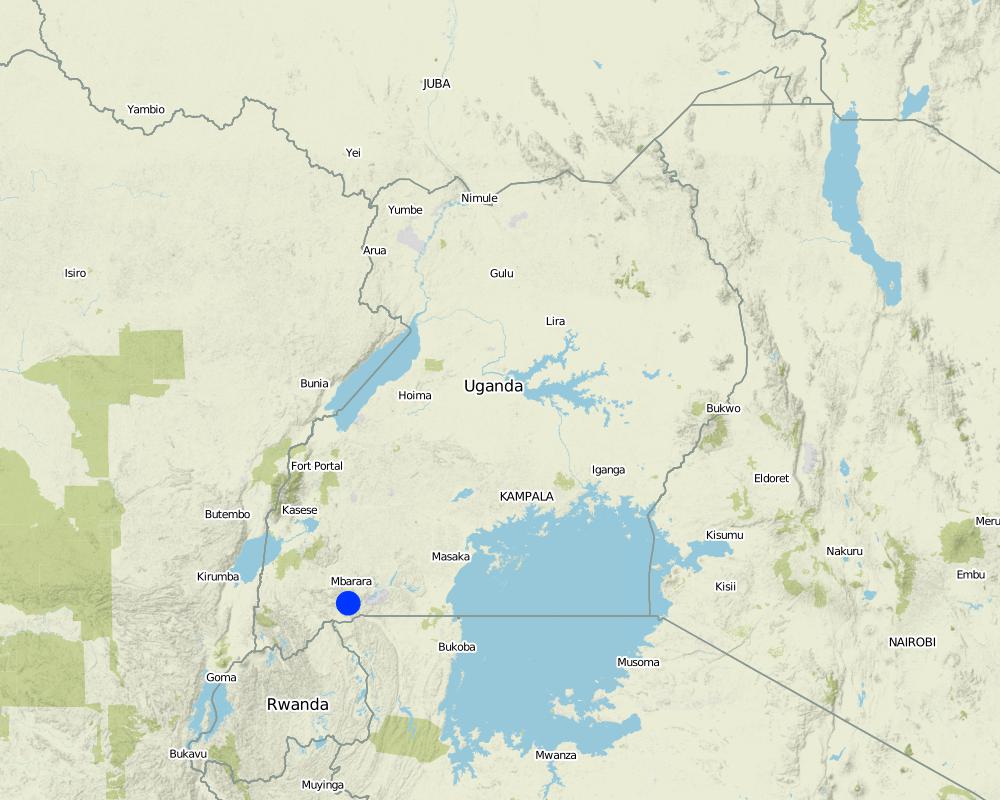

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Uganda

Further specification of location:

Mbarara District (Rubagano, Mwizi)

Comments:

Boundary points of the Technology area: -0.85203 30.62232; -0.85850 30.62204; -0.85792 30.62021

Total area covered by the SLM Technology is 0.001 km2.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- adapt to climate change/ extremes and its impacts

3.2 Current land use type(s) where the Technology is applied

Cropland

- Perennial (non-woody) cropping

- Tree and shrub cropping

Perennial (non-woody) cropping - Specify crops:

- banana/plantain/abaca

Tree and shrub cropping - Specify crops:

- coffee, open grown

Specify:

Longest growing period in days: 120 Longest growing period from month to month: September to December Second longest growing period in days: 90 Second longest growing period from month to month: February to May

Waterways, waterbodies, wetlands

Comments:

Major land use problems (compiler’s opinion): Loss of vegetation, soil erosion and very low ground water level. Difficulty in finding access to water for domestic use, livestock and crop irrigation.

Major land use problems (land users’ perception): Women and children walk very long distances in search of water from permanent natural wells.

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- water harvesting

3.6 SLM measures comprising the Technology

structural measures

- S5: Dams, pans, ponds

Comments:

Main measures: structural measures

3.7 Main types of land degradation addressed by the Technology

water degradation

- Hs: change in quantity of surface water

- Hp: decline of surface water quality

Comments:

Main type of degradation addressed: Hs: change in quantity of surface water, Hp: decline of surface water quality

Main causes of degradation: soil management (Removal of vegetation cover), deforestation / removal of natural vegetation (incl. forest fires) (Forests harvested for fuel wood, charcoal, agriculture etc.), other natural causes (avalanches, volcanic eruptions, mud flows, highly susceptible natural resources, extreme topography, etc.) specify (Steep slopes increase the speed of runoff and soil erosion)

Secondary causes of degradation: change of seasonal rainfall (Climate change effects of human activity), droughts (Longer dry spells as a result of climatic changes), poverty / wealth (Cannot afford manure or fertilizers to make soil more productive so forest is cut to create more agricultural land)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

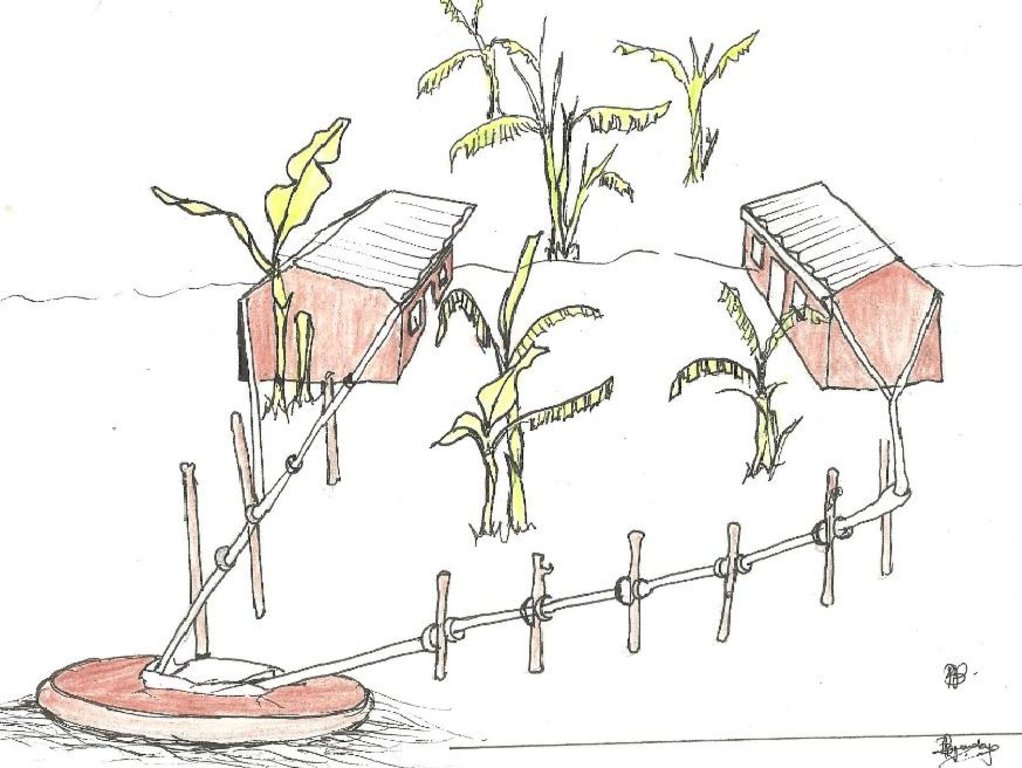

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Details of rainwater harvesting system: roof catchment, gutters and underground storage tank

Location: Rubagano, Mwizi Sub-county, Mbarara District. Uganda

Date: 18 December 2013

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: low (Artisan's work once the land user has decided on the size of the water tank required)

Main technical functions: water harvesting / increase water supply

Secondary technical functions: control of dispersed runoff: retain / trap, control of concentrated runoff: drain / divert, water spreading

Dam/ pan/ pond

Depth of ditches/pits/dams (m): d=3.0

Width of ditches/pits/dams (m): r=2.0

Length of ditches/pits/dams (m): n/a

Specification of dams/ pans/ ponds: Capacity 38m3

Catchment area: 900 m2m2

Beneficial area: 900 m2m2

For water harvesting: the ratio between the area where the harvested water is applied and the total area from which water is collected is: 1:0.1

Author:

Byonabye Proscovia, Kabale, Uganda

4.2 General information regarding the calculation of inputs and costs

other/ national currency (specify):

UGX

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

2500.0

Indicate average wage cost of hired labour per day:

10.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Tank construction | Throughout the year |

| 2. | Procurement and raising of collection gutters | Throughout the year |

| 3. | Wooden poles | Throughout the year |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 500.0 | 500.0 | 100.0 |

| Equipment | Tools | ha | 1.0 | 30.0 | 30.0 | 100.0 |

| Construction material | Wood | ha | 1.0 | 16.0 | 16.0 | 100.0 |

| Construction material | Bricks | ha | 1.0 | 400.0 | 400.0 | 100.0 |

| Construction material | Cement | ha | 1.0 | 420.0 | 420.0 | 100.0 |

| Construction material | Sand | ha | 1.0 | 160.0 | 160.0 | 100.0 |

| Total costs for establishment of the Technology | 1526.0 | |||||

| Total costs for establishment of the Technology in USD | 0.61 | |||||

Comments:

Duration of establishment phase: 2 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Tank maintenance (above ground) | Once a year |

| 2. | Gutter replacement | Twice a year |

| 3. | Wooden poles | Twice a year |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 80.0 | 80.0 | 100.0 |

| Equipment | Tools | ha | 1.0 | 10.0 | 10.0 | 100.0 |

| Construction material | Wood | ha | 1.0 | 4.0 | 4.0 | 100.0 |

| Construction material | Bricks | ha | 1.0 | 40.0 | 40.0 | 100.0 |

| Construction material | Cement | ha | 1.0 | 42.0 | 42.0 | 100.0 |

| Construction material | Sand | ha | 1.0 | 40.0 | 40.0 | 100.0 |

| Total costs for maintenance of the Technology | 216.0 | |||||

| Total costs for maintenance of the Technology in USD | 0.09 | |||||

Comments:

Machinery/ tools: Pick-axe, hand hoe, panga

The calculations were done for a 38.0 cubic meter tank constructed in September 2013

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Skilled labor for the construction of the underground tank

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Average annual rainfall for Rubagano is >1200 mm

Agro-climatic zone

- sub-humid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Altitudinal zone: 1501-2000 m a.s.l (Ranked 1, rubagano has an average altitude of 1700 m a.s.l) and 1001-1500 m a.s.l. (ranked 2)

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility: Low (ranked 1) and medium (ranked 2)

Soil drainage/infiltration: Medium

Soil water storage capacity: Medium (ranked 1) and low (ranked 2)

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

poor/ none

Water quality (untreated):

poor drinking water (treatment required)

5.5 Biodiversity

Species diversity:

- low

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

- mixed (subsistence/ commercial)

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Population density: 50-100 persons/km2

Annual population growth: 2% - 3%

1% of the land users are very rich and own 10% of the land.

15% of the land users are rich and own 20% of the land.

80% of the land users are average wealthy and own 65% of the land (Have an iron roof house, some livestock and land for cultivation).

4% of the land users are poor and own 5% of the land.

Off-farm income specification: Similar statistics for all types of land users as far as off-farm income is concerned

Level of mechanization: Manual work (All land is cultivated manually)

Market orientation of production system: Mixed (ranked 1, most farmers cultivate banana plantations for subsistence and commercial use) and subsistence (ranked 2, a few farmers cultivate for subsisce)

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- open access (unorganized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

wood production

risk of production failure

production area

Water availability and quality

drinking water availability

Income and costs

expenses on agricultural inputs

farm income

Socio-cultural impacts

food security/ self-sufficiency

health situation

SLM/ land degradation knowledge

situation of socially and economically disadvantaged groups

Comments/ specify:

Women and children

Improved livelihoods and human well-being

Comments/ specify:

Women and children no longer have to walk long distances in search of water.

Ecological impacts

Water cycle/ runoff

water quantity

water quality

harvesting/ collection of water

surface runoff

evaporation

Soil

soil moisture

Biodiversity: vegetation, animals

plant diversity

6.2 Off-site impacts the Technology has shown

water availability

downstream flooding

damage on public/ private infrastructure

Comments/ specify:

E.g. Roads

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

very positive

Comments:

The technology may appear expensive to the farmer at the time of establishment but it is cost-effective in the long-term.

6.5 Adoption of the Technology

If available, quantify (no. of households and/ or area covered):

25

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 51-90%

Comments:

20% of land user families have adopted the Technology with external material support

5 land user families have adopted the Technology with external material support

80% of land user families have adopted the Technology without any external material support

20 land user families have adopted the Technology without any external material support

There is a moderate trend towards spontaneous adoption of the Technology

Comments on adoption trend: Regardless of the high costs involved, improved water security has encouraged farmers to adapt the technology.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Makes water for drinking and domestic use more readily available to the household How can they be sustained / enhanced? Encourage adoption and maintenance through farmer-to-farmer information |

|

Saves women and children from walking long distances in search of clean water How can they be sustained / enhanced? Empower women and children to demand and obtain rooftop water harvesting at home |

|

Rooftop harvested water is cleaner than trapped runoff used by many members of the community How can they be sustained / enhanced? Help households to acquire materials for rooftop water harvesting |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Technology is expensive to establish | Support government and private sector to subsidize tanking systems for farmers |

| Requires technical expertise especially in concrete preparation to prevent cracks and leakages | Ensure farmers who express the need to adapt get access to construction technicians |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

Kagera TAMP project website

Available from where? Costs?

www.fao.org/nr/kagera/en

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules