Domestic Biogas Plant for fuel and organic fertilizer [Uganda]

- Creation:

- Update:

- Compiler: JOSELINE KASHAGAMA

- Editor: Kamugisha Rick Nelson

- Reviewers: Nicole Harari, Udo Höggel, Donia Mühlematter

Bayogasi

technologies_3371 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Wodonya Patrick

+256 786 189490

Bulambuli District Eastern Uganda

Uganda

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

National Agricultural Research Organisation (NARO) - Uganda1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

19/10/2017

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

Nee

Comments:

Biogas protects the environment through reduced tree cutting and emission of harmful gases and the bi- product removed from the digester is used as organic fertilizer that boosts crop production.

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Domestic biogas plant converts livestock manure into biogas and organic fertilizer. The technique uses cow dung to produce methane gas for lighting and heating.

2.2 Detailed description of the Technology

Description:

Domestic biogas plants convert livestock manure into biogas and bio-slurry, a form of organic fertilizer (fermented manure). Biogas is a renewable energy or gas produced by the breakdown of organic matter in the absence of oxygen. Most people in Uganda, especially in rural areas, don’t have access to electricity and mostly rely on firewood and charcoal (mostly in urban areas). This has led to depletion of forests since these forests are the main supply of wood fuel. The domestic biogas technique uses fresh cow dung to produce methane gas for lighting and heating.

This technology is viable for smallholder farmers with livestock that are capable of producing 25 kg of fresh dung per day, typically about five indigenous cows. This makes the technology suitable for smallholders in developing countries. Fresh cow dung is collected and mixed with water at a ratio of 1:1, depending on the thickness of the dung, to produce a free-flowing mixture. The mixture is poured into the digester where microbes break it down under an oxygen-free environment and in the process release methane gas which is harvested in a cylinder and piped straight into the home for lighting and/ or heating.

Dimensions for the Digester (4m in diameter and 3 m in depth). Overflow tank/ Outlet is 2 meters by 2 meters. Materials used in the construction of the plant include sand, cement, bricks, iron rods, gravel and water. Biogas stove, lamp and its appliances and gas controller or pressure gauge are connected after the construction of the biogas plant which can be purchased from specified outlets on the urban markets.

Production and use of biogas protects the environment through reduced tree cutting and emission of harmful greenhouse gases (GHG). It also eases the workload of rural women and children by providing a safe and cheap source of fuel since it reduces the risk encountered by children and women looking for firewood and spares their time that would otherwise be spent in the process. The bi-product (bio-slurry) removed from the digester at the end of the process is used as organic fertilizer which boosts crop productivity and is a highly nutritious feed supplement for animals.

The technology has safety issues especially on the side of children when it comes to the flammable gas.

2.3 Photos of the Technology

2.4 Videos of the Technology

Comments, short description:

The video couldn't be captured since the largest part of the biogas plant is below the ground and the system was constructed long ago before the documentation process.

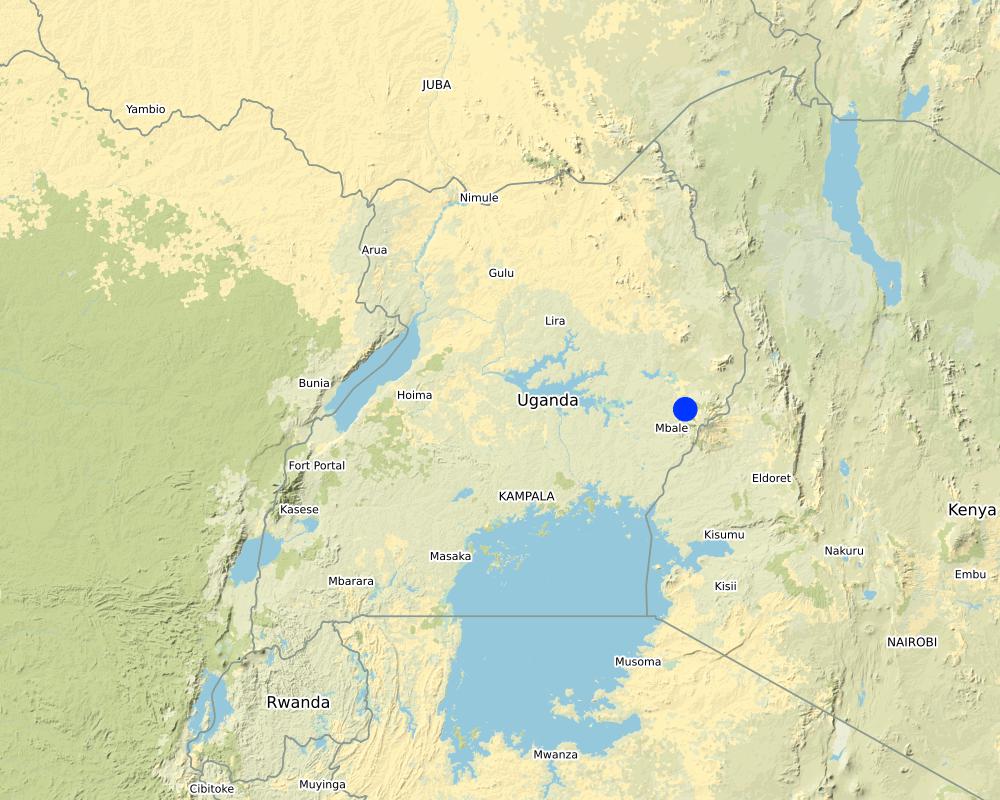

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Eastern Uganda

Further specification of location:

Sisiyi Sub county, Gibuzale Parish, Bulabuli District

Comments:

1.2899 , 34.3551

Map

×2.6 Date of implementation

Indicate year of implementation:

2016

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Kawcom Uganda constructs Biogas Plant for its coffee suppliers.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- conserve ecosystem

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Perennial (non-woody) cropping

Main crops (cash and food crops):

Coffee and Bananas

Grazing land

Intensive grazing/ fodder production:

- Cut-and-carry/ zero grazing

Main animal species and products:

Cows

Comments:

The technology is applied around the land user's homestead.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

Irrigation performed during the dry season. i.e. around mid November to mid March while the river Gibuzale provides water for the biogas plant and for irrigation.

Number of growing seasons per year:

- 3

Specify:

One can have 2 agricultural seasons if a field is NOT near a water source. Three (3) such season are possible if the field is near a river.

Livestock density (if relevant):

3 cows

3.4 SLM group to which the Technology belongs

- natural and semi-natural forest management

- integrated soil fertility management

- energy efficiency technologies

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

structural measures

- S10: Energy saving measures

management measures

- M6: Waste management (recycling, re-use or reduce)

3.7 Main types of land degradation addressed by the Technology

biological degradation

- Bc: reduction of vegetation cover

- Bq: quantity/ biomass decline

Comments:

The technology addresses biological degradation (reduction of vegetation cover) through reduced cutting of trees for firewood.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

Comments:

Biogas reduces and prevents land degradation through reduction in deforestation to supply firewood and charcoal.

4. Technical specifications, implementation activities, inputs, and costs

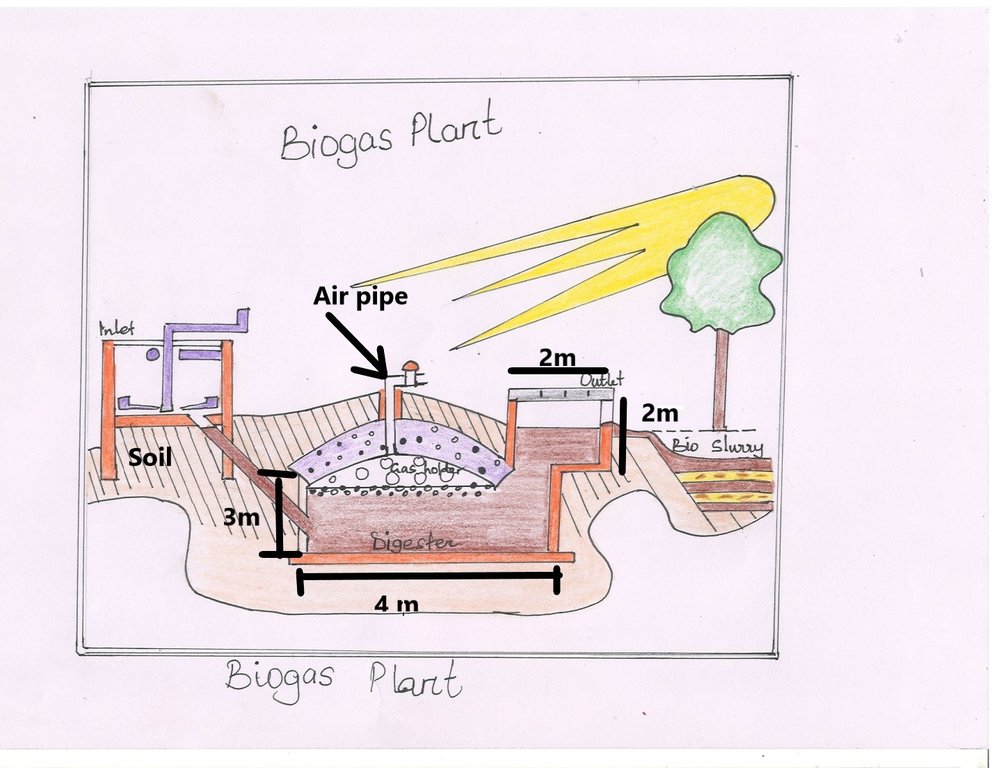

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

Components and Construction of the Bio gas plant

The size of the biogas plant is based on the availability of raw materials, use and financial status. The Biogas plant has the following components the inlet pipe/ tank, the digester, the outlet tank and gas pipe. Materials used in the construction of the plant include Sand, Cement, bricks, iron rods, gravel and water.

The land should be leveled before construction after which the pits are evacuated in their proper sizes and depth. After which construction of the walls begins with a mixture of cement and sand with a ratio of 1:4.

The inlet pipe is about 15cm in diameter which is connected to the digester. Dimensions for the Digester are 4m in diameter and 3m in depth with the thickness of 35cm and strong enough to with stand the load since they are partially buried under ground. The gas pipe is connected to the digester which carries the gas to the point of utilization, such as a stove or lamp. The digester is connected to the overflow tank which is 2 meters in diameter and 2meters in depth.

Biogas stove, lamp and its appliances and gas controller or gauge are connected after the construction of the biogas plant.

Production of Biogas

Biogas is produced from biodegradable materials such as animal dung mixed with water. Before the dung is fed into the plant, it is mixed with water in a tank or basin to give a solid content of 1: 1.5 ratios in the slurry. The mixture is discharged into the digester through the inlet pipe. The mixture ferments inside this digester and biogas is produced through bacterial action, the gas of which settles on top of the slurry in the digester which goes through a gas pipe connected on top of the tank. The gas pipe has a gas/pressure regulator which controls the outlet pressure of the gas to the gas burner or bulb. The digested slurry is discharged into the outlet tank through the outlet opening and use a fertiliser.

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Construction Materials

Specify volume, length, etc. (if relevant):

Volume

Specify currency used for cost calculations:

- US Dollars

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

3600.0

Indicate average wage cost of hired labour per day:

$ 1.389

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Plan and take measurements | Structural | Not applicable |

| 2. | Buy and deliver the construction materials | Structural | Not applicable |

| 3. | Dig the pits | Structural | Not applicable |

| 4. | Build the concrete | Structural | Not applicable |

| 5. | Put the pipes | Structural | Not applicable |

| 6. | Connect to the stove and lamp | Structural | Not applicable |

4.5 Costs and inputs needed for establishment

If possible, break down the costs of establishment according to the following table, specifying inputs and costs per input. If you are unable to break down the costs, give an estimation of the total costs of establishing the Technology:

451.16

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Man labour (Digging the holes)) | Person-days | 2.0 | 13.89 | 27.78 | 50.0 |

| Labour | Man labour (Building) | person-days | 20.0 | 4.17 | 83.4 | 50.0 |

| Equipment | Stove | piece | 1.0 | 27.78 | 27.78 | 50.0 |

| Equipment | Lamp | Piece | 1.0 | 27.78 | 27.78 | 100.0 |

| Construction material | Bricks | Piece | 700.0 | 0.042 | 29.4 | 50.0 |

| Construction material | Cement | Bag (50kg) | 11.0 | 8.89 | 97.79 | 50.0 |

| Construction material | Sand | Tonnes | 1.0 | 41.67 | 41.67 | 50.0 |

| Construction material | Stones | Tonnes | 0.5 | 27.78 | 13.89 | 50.0 |

| Other | Pipes | piece @ 10m | 3.0 | 4.17 | 12.51 | 50.0 |

| Other | Wire goose | Meters | 3.0 | 1.94 | 5.82 | 50.0 |

| Other | Transportation | Trip | 3.0 | 27.78 | 83.34 | 50.0 |

| Total costs for establishment of the Technology | 451.16 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Kawacon Uganda Limited

Comments:

Kawacom (U) Ltd imports coffee thus it supports coffee farmers who are its suppliers.

The length of the gas pipes also depends on the distance from the plant to the homestead.

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Manual mixing of the dung & water | Management | Every Morning |

| 2. | Add mixture (dung & water) | Management | Every morning |

| 3. | Emptying of the the overflow | Management | When necessary |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

If possible, break down the costs of maintenance according to the following table, specifying inputs and costs per input. If you are unable to break down the costs, give an estimation of the total costs of maintaining the Technology:

5.32

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Man Labour | persons- days | 2.0 | 1.39 | 2.78 | 100.0 |

| Equipment | Mixing Basin | piece | 1.0 | 1.39 | 1.39 | 100.0 |

| Fertilizers and biocides | Cow dung | kg | 40.0 | 0.028 | 1.12 | 100.0 |

| Fertilizers and biocides | Water | Litres | 20.0 | 0.0014 | 0.03 | 100.0 |

| Total costs for maintenance of the Technology | 5.32 | |||||

Comments:

The maintenance costs were estimated at a two weekly basis. Most smaller holders don't incur any costs on maintenance since labour and acquisition of the dung is got from their own cows and from friends which is free of charge and use family labour. The cost for water accounts for labour used to fetch the water from the stream

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The construction costs, determined by the size of the biogas plant.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1600.00

Specifications/ comments on rainfall:

The zone receives a bi-modal pattern of rainfall, with the wettest months being April and October, while July to August and December to February are relatively dry.

Indicate the name of the reference meteorological station considered:

Buginyanya Zonal Agricultural Research and Development Institute - BugiZARDI

Agro-climatic zone

- humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

on surface

Availability of surface water:

good

Water quality (untreated):

good drinking water

Is water salinity a problem?

Nee

Is flooding of the area occurring?

Nee

Comments and further specifications on water quality and quantity:

The area gets water from River Gibuzale that flows through the village.

5.5 Biodiversity

Species diversity:

- high

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- commercial/ market

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

- men

Age of land users:

- children

- middle-aged

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

Comments:

The land user owns 0.4 ha of land which is considered small in the area compared to other land owners who own over 4 ha.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- communal (organized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

800kg

Quantity after SLM:

1200kg

Comments/ specify:

The land user uses the organic manure in his coffee plantation which has greatly led to increased yields.

crop quality

Comments/ specify:

Bigger coffee beans

energy generation

Comments/ specify:

Use of biogas for lighting and heating

Income and costs

expenses on agricultural inputs

Comments/ specify:

No costs on purchase of fertilizer since the land user applies the bi-product (fermented manure) of the biogas.

farm income

Quantity before SLM:

UGX 1040000

Quantity after SLM:

UGX 1560000

Comments/ specify:

More yields hence more incomes

workload

Comments/ specify:

No more fetching firewood for cooking

Socio-cultural impacts

food security/ self-sufficiency

health situation

Comments/ specify:

Use of biogas reduces effects of smoke inhaled through the use of firewood hence reduced lung diseases.

SLM/ land degradation knowledge

Comments/ specify:

Increased knowledge on the use of organic manure as a sustainability practice.

situation of socially and economically disadvantaged groups

Comments/ specify:

Biogas use favours women and the disabled as it reduces the workload of fetching firewood especially from distant areas or forests.

Ecological impacts

Soil

soil moisture

Comments/ specify:

The bi-product from the biogas plant is watery hence its used in the farm to moist the soil

soil cover

Comments/ specify:

Use of biogas reduces tree cutting

soil accumulation

Comments/ specify:

The bi- product removed from the digester at the end of the process is used as organic fertilizer which increases activities of soil organisms hence soil accumulation.

nutrient cycling/ recharge

Comments/ specify:

The bi- product removed from the digester at the end of the process is used as organic fertilizer

soil organic matter/ below ground C

Comments/ specify:

Use of organic manure supports multiplication of organic matter in the soil

6.2 Off-site impacts the Technology has shown

groundwater/ river pollution

Comments/ specify:

The dung and urine from the animals is used as material in the biogas plant which would have been washed away by run off water into the river.

damage on neighbours' fields

Comments/ specify:

The user doesn't have to encourage on the neighbours' land to fetch firewood since biogas is now used for heating.

impact of greenhouse gases

Comments/ specify:

Reduced bad smells from the dung

Comments regarding impact assessment:

The technology has less impact on the off site since its practiced in the land user's homestead.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well | |

| seasonal rainfall | wet/ rainy season | decrease | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

Comments:

No maintenance costs involved hence higher benefits.

6.5 Adoption of the Technology

- 1-10%

If available, quantify (no. of households and/ or area covered):

10

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

All received support from Kawacom (U) Ltd.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Nee

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| It eases the workload by providing a safe and cheap source of fuel compared to firewood |

| The bi- product at the end of the process is used as organic fertilizer that boosts crop production |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Biogas protects the environment through reduced deforestation hence climate change mitigation. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Inadequate dung | Collects dung from cattle owners in the area |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Safety issues especially on the side of children when it comes to the flammable gas | Continuous safety education measures to prevent fire out breaks |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

1

- interviews with land users

2 informats

- interviews with SLM specialists/ experts

1

- compilation from reports and other existing documentation

2

7.3 Links to relevant information which is available online

Title/ description:

Uganda Domestic Biogas Programme (UDBP)

URL:

https://www.ngoaidmap.org/projects/3031

Title/ description:

Power for the Poor From Animal Manure, Food Waste

URL:

https://www.sierraclub.org/sierra/2018-1-january-february/faces-clean-energy/power-for-poor-animal-manure-food-waste

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules