Gravity type inverted tyre structure [South Africa]

- Creation:

- Update:

- Compiler: Mirjam Staehli

- Editor: –

- Reviewer: David Streiff

Swaartekrag tipe omgedopte bande struktuur (Afrikaans)

technologies_1374 - South Africa

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Du Toit Boeta P.

Marico Bushveld Soil Conservation Committee, South Africa

South Africa

SLM specialist:

Meiring C. H.

Marico Bushveld Soil Conservation Committee, South Africa

South Africa

1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

12/12/2003

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.5 Reference to Questionnaire(s) on SLM Approaches

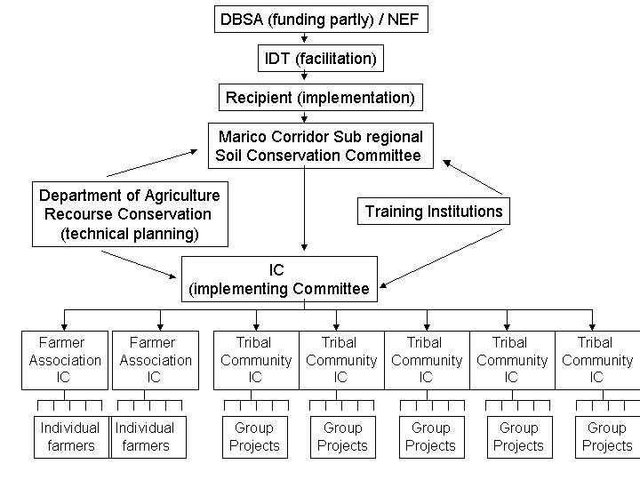

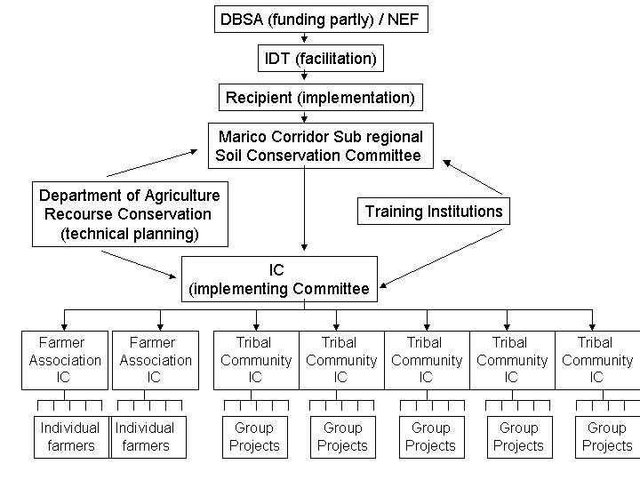

Community driven Protection of the Molatedi Dam Catchment … [South Africa]

Development and capacity building in participating communities through the implementation of measures to prevent topsoil losses through erosion in the Molatedi dam catchment area.

- Compiler: Philippe Zahner

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

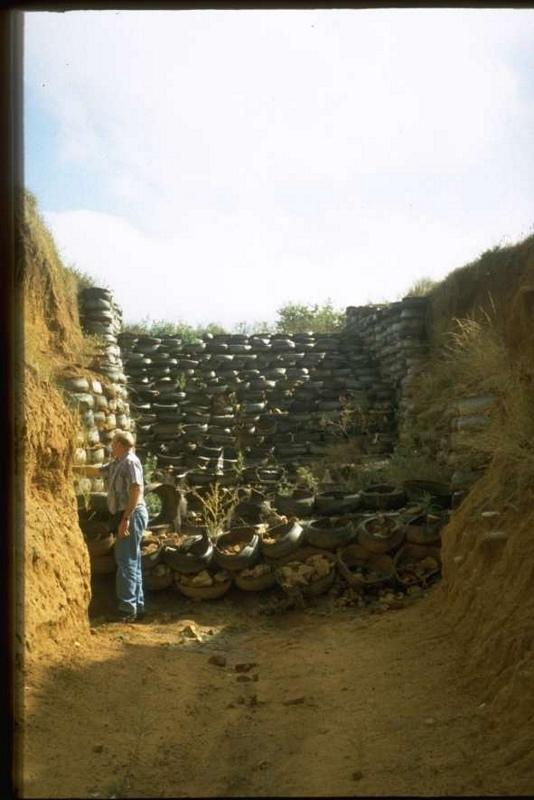

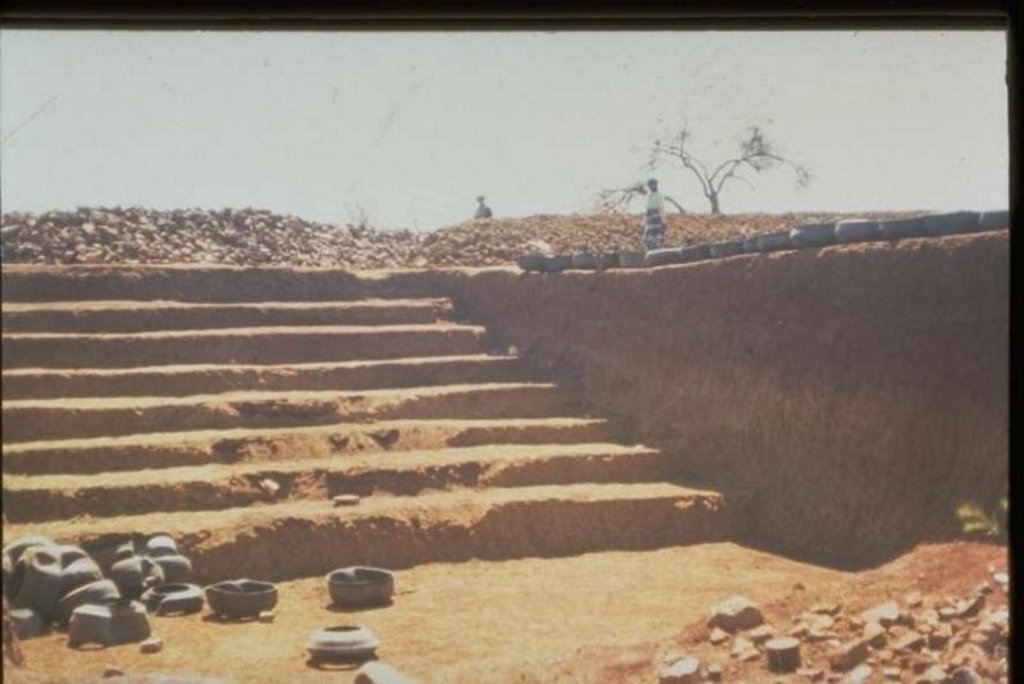

Stabilising of gully erosion by means of gravity type inverted tyre structures filled with stone.

2.2 Detailed description of the Technology

Description:

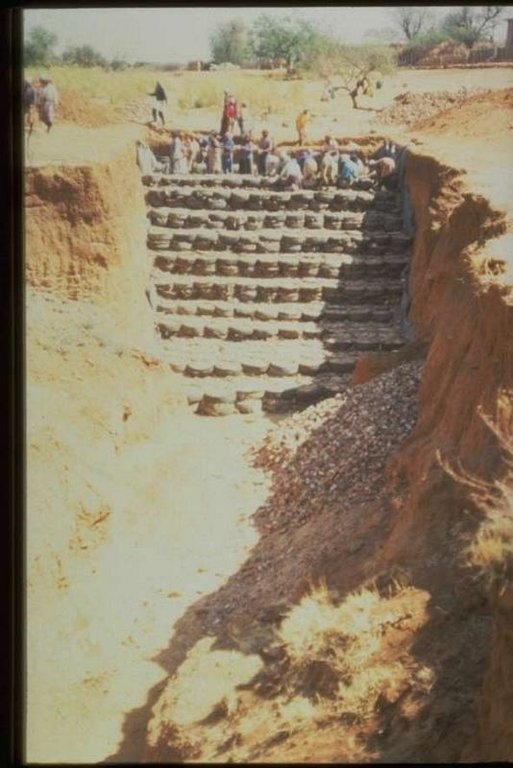

Gravity type inverted tyre structure is bound together with wire and filled with stone.

The valley floor gully head drop is protected to prevent further erosion. Survey planning and design are important for the construction of the structure.

Maintenance includes prevention of leakage alongside the structure. The walls to prevent the erosion of soil are filled in. Ensure that the top layer stones are not washed away.

The structure is situated in a semi-arid area which is highly degraded through overgrazing.

Due to the location of the structure, further erosion was stopped that would have endangered some of the homesteads.

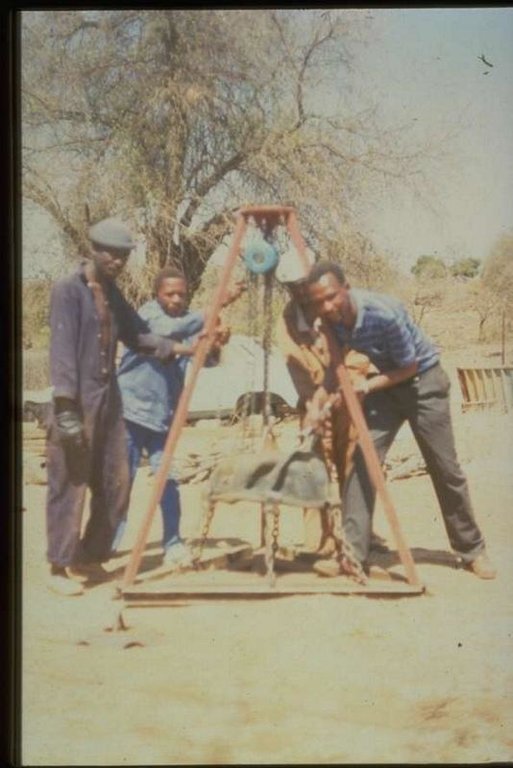

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

South Africa

Region/ State/ Province:

North West Province

Further specification of location:

Marico District

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

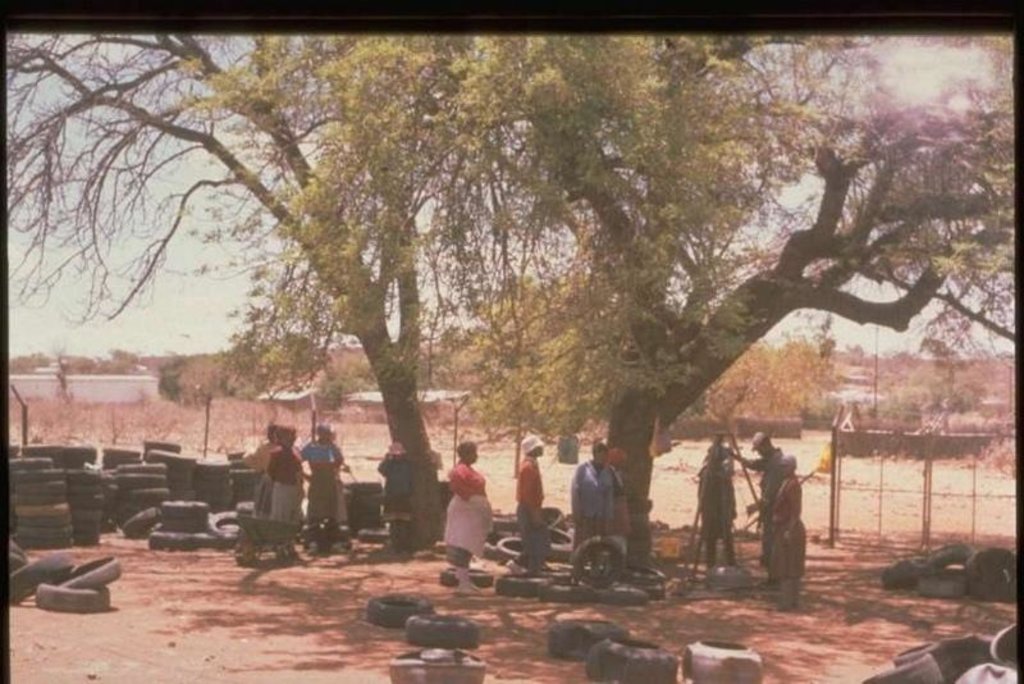

Developed by technician department Resource Conservation and farmer from local conservation committee.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

3.2 Current land use type(s) where the Technology is applied

Grazing land

Comments:

Major land use problems (compiler’s opinion): Lack of landuse planning. Overgrazing. Overpopulation.

Major land use problems (land users’ perception): Lack of grazing land, frequent occurrence of droughts.

Constraints of infrastructure network (roads, railways, pipe lines, power lines): Not planning for access roads in the village

3.3 Further information about land use

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 240; Longest growing period from month to month: Sep - Apr

3.4 SLM group to which the Technology belongs

- cross-slope measure

3.5 Spread of the Technology

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, indicate approximate area covered:

- 1-10 km2

Comments:

Total area covered by the SLM Technology is 12 km2.

Same technology was also applied in the Molatedi tribal village (70 km away in the same catchment area)

3.6 SLM measures comprising the Technology

structural measures

- S1: Terraces

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wg: gully erosion/ gullying

Comments:

Secondary types of degradation addressed: Wt: loss of topsoil / surface erosion

Main causes of degradation: overgrazing, droughts, education, access to knowledge and support services (Lack of knowledge - Lack of training & awareness)

Secondary causes of degradation: over-exploitation of vegetation for domestic use, other human induced causes (specify) (Agricultural causes - Lack of extension and planning), land tenure (Land subdivision - Only if someone own land (commercial farmers)), poverty / wealth (Lack of employment), Lack of enforcement of legislat./authority (Regarding natural resources)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

Comments:

Secondary goals: prevention of land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

further downstream another tyre construction trapping the silt, behind the structure silting up and vegetation is well growing

North West

Date: April 1999

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: moderate

Main technical functions: control of dispersed runoff: impede / retard

Structural measure: Gully head drop structure

Construction material (earth): wire iron posts, plastic material, geotextilemembranes (bidim-kaymat) -water permeable soil exclude

Lateral gradient along the structure: 50%

4.3 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Rand

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

6.0

Indicate average wage cost of hired labour per day:

1.50

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 9400.0 | 9400.0 | |

| Equipment | Tools | ha | 1.0 | 600.0 | 600.0 | |

| Equipment | Tyre averting tool machine | ha | 1.0 | 100.0 | 100.0 | |

| Construction material | Geotextile membrane | ha | 1.0 | 2000.0 | 2000.0 | |

| Construction material | Wire 2mm (rolls a 50kg) | ha | 1.0 | 330.0 | 330.0 | |

| Construction material | Fully galvanised iron | ha | 1.0 | 50.0 | 50.0 | |

| Total costs for establishment of the Technology | 12480.0 | |||||

Comments:

Duration of establishment phase: 0 month(s)

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

Comments:

The complete structure.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Labour - very low productivity. Transportation of tyres. Tying wire must be cut economically according to need otherwise huge waste take place.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Thunderstorms, heavy rainfall

Agro-climatic zone

- semi-arid

Summer rainfall

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- concave situations

Comments and further specifications on topography:

Soil fertility is low

Soil drainage / infiltration is good

Soil water storage capacity is medium

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- low (<1%)

5.6 Characteristics of land users applying the Technology

Off-farm income:

- > 50% of all income

Relative level of wealth:

- poor

Indicate other relevant characteristics of the land users:

Population density: 100-200 persons/km2

Annual population growth: 3% - 4%

and own 100% of the land (Communal land belongs to the tribe).

Off-farm income specification: State pensions- head of family work elsewhere.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

Land use rights:

- open access (unorganized)

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Income and costs

diversity of income sources

Comments/ specify:

short term job creation

Socio-cultural impacts

community institutions

SLM/ land degradation knowledge

Ecological impacts

Soil

soil loss

6.2 Off-site impacts the Technology has shown

downstream flooding

downstream siltation

spending on consumer goods in shops in area

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

6.5 Adoption of the Technology

- 10-50%

If available, quantify (no. of households and/ or area covered):

20 percent of the area

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

100% of land user families have adopted the Technology with external material support

100 land user families have adopted the Technology with external material support

Comments on acceptance with external material support: estimates

There is no trend towards spontaneous adoption of the Technology

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Labour intensive, job creation |

| Received training |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Low cost material |

| Labour intensive can be utilized without machinery |

| Mostly unskilled labour can be used. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Storm water walls are in the way of motor vehicles, travelling in the village | Plan roads properly - construct alternative road around wall. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Costly if manual labour is unproductive | Maintain high productivity. Train workers, work smart, contract work |

| Transport cost of tyres is a big factor. | Utilize tyres from nearby areas. Utilizes big transport trucks with big loading capacity. |

| Need machine to invert tyres | Tool well and practically constructed - operators trained. |

| Must technically be well planned and constructed. | Use skilled technician for planning and to assist workers during construction. |

Links and modules

Expand all Collapse allLinks

Community driven Protection of the Molatedi Dam Catchment … [South Africa]

Development and capacity building in participating communities through the implementation of measures to prevent topsoil losses through erosion in the Molatedi dam catchment area.

- Compiler: Philippe Zahner

Modules

No modules