Small pit cultivation for maize, sorghum and millet (Chololo pits) [Tanzania, United Republic of]

- Creation:

- Update:

- Compiler: Patrick Gervas Mbanguka Lameck

- Editor: –

- Reviewer: David Streiff

mashimo ya chololo (Kiswahili)

technologies_1395 - Tanzania, United Republic of

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Inades Formation Tanzania (Inades Formation Tanzania)1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

07/08/2000

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Small planting pits are used for the cultivation of maize, sorghum and millet in order to improve water harvesting

2.2 Detailed description of the Technology

Description:

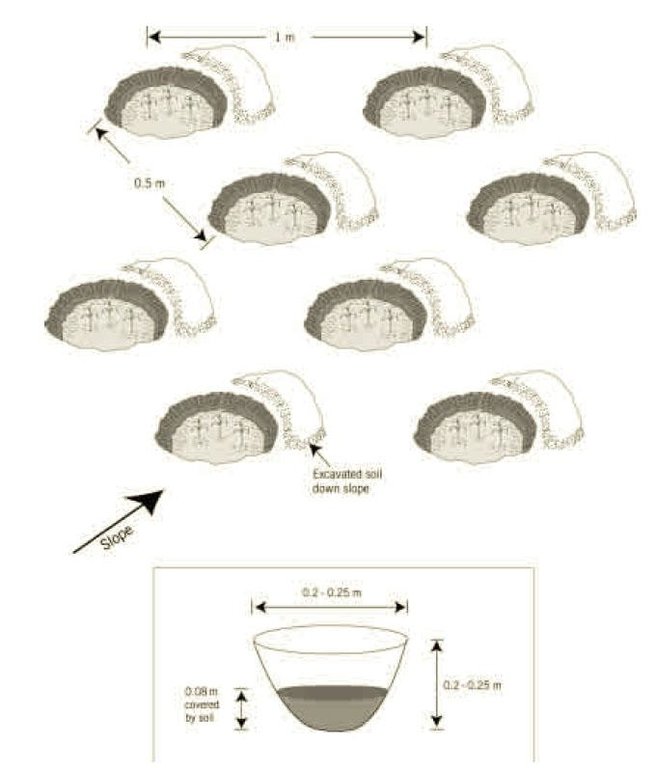

Pits of about 0.20 - 0.25 m deep and 0.20 - 0.25 m diameter are excavated in lines across the slope. The spacing is approximately 0.5 m from pit centre to pit centre within lines and 1.0 m between lines. During excavation soil is normally heaped below each pit. The spaces between pits are not cultivated. Pits are made during the land preparation period, before the rains. Planting millet seed in the pits follows. Part of the excavated soil is returned to cover the seed, but a depression remains to permit water harvesting. Sungula has a stick – that he shows to visitors - with which he measures depth. Construction of contour bunds to control runoff from outside the plot is carried out in places. There is no strict design, as the farmer is still testing various types. The contour bunds protect the pits (which partially fill with sediment during the season) from excess runoff, and minimise soil erosion.

Purpose of the Technology: The primary purpose is to improve crop production. In terms of soil and water conservation, the moisture status in the soil is raised through water harvesting. Simultaneously, sheet erosion is controlled.

Establishment / maintenance activities and inputs: Pits are generally desilted on an annual basis, but new ones are only constructed, in spaces between the original pits, after a few years. Maintenance is also required for the bunds between the pits.

Natural / human environment: Kenneth Sungula and his family are dependent on his 4 hectares of gently sloping land in Chololo2 village. The family own no livestock, other than a few chickens. They grow millet and cowpeas as their main annual crops. Neither Sungula nor his wife are literate. His novel technology dates back to 1978,

when Sungula stumbled upon the idea by accident. He noted that some plants growing in a small depression in the ground were strongly outperforming others nearby. He then began to experiment by deliberately creating small planting pits. Sungula claims that ‘his stomach taught him’ how to make the pits. His meaning is clear: hunger drove him to find a more productive system of production. These chololo pits, named after the local village, hold runoff, and the spaces between the pits act as micro-catchments. The extra moisture is vital in initial establishment of crops in this semi-arid area, where the first rains can be erratic.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Tanzania, United Republic of

Region/ State/ Province:

Dodoma

Further specification of location:

Dodoma urban

Map

×2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

Comments (type of project, etc.):

Mr Kenneth Sangula is the farmer who developed the technology

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Main crops (cash and food crops):

major cash crop: Sorghum and millet

major food crop: Maize

other: Groundnuts

Comments:

Major land use problems (compiler’s opinion): removal of top soil by gully and sheet erosion

Major land use problems (land users’ perception): poor rainfall, removal of top soil by gully and sheet erosion

3.3 Further information about land use

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 150; Longest growing period from month to month: Nov - Mar

3.4 SLM group to which the Technology belongs

- water harvesting

3.5 Spread of the Technology

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, indicate approximate area covered:

- 10-100 km2

Comments:

Total area covered by the SLM Technology is 25 km2.

3.6 SLM measures comprising the Technology

structural measures

- S4: Level ditches, pits

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

water degradation

- Ha: aridification

Comments:

Secondary types of degradation addressed: Cn: fertility decline and reduced organic matter content, Ha: aridification

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

Chololo planting pits

Location: Dodoma. Tanzania

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: low

Main technical functions: control of concentrated runoff: retain / trap, water harvesting / increase water supply

Secondary technical functions: control of concentrated runoff: impede / retard, reduction of slope length

Retention/infiltration ditch/pit, sediment/sand trap

Vertical interval between structures (m): 0.9

Spacing between structures (m): 0.3

Depth of ditches/pits/dams (m): 0.9

Width of ditches/pits/dams (m): 0.9

Structural measure: bunds/banks: contour

Vertical interval between structures (m): 0.9

Height of bunds/banks/others (m): 0.4

Width of bunds/banks/others (m): 0.9

Construction material (earth): escavated top soil

Lateral gradient along the structure: 15.00%

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

ha

Specify currency used for cost calculations:

- US Dollars

Indicate average wage cost of hired labour per day:

1.90

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | land clearing, digging pits | Structural | Aug-Oct |

| 2. | sowing and 3'' covering | Structural | Oct |

| 3. | weeding | Structural | dry season |

| 4. | construction of big bunds | Structural | oct-nov |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | persons/day/ha | 336.0 | 1.9 | 638.4 | 100.0 |

| Equipment | Tools | ha | 1.0 | 6.25 | 6.25 | 100.0 |

| Fertilizers and biocides | Compost / manure | ha | 1.0 | 124.0 | 124.0 | 100.0 |

| Total costs for establishment of the Technology | 768.65 | |||||

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Repair small bunds | Structural | after/3-6 times |

| 2. | construction of protecting bunds | Structural | Oct- Nov/annually |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Repair small bunds an construction | persons/day/ha | 104.0 | 1.9 | 197.6 | 100.0 |

| Equipment | Tools | ha | 1.0 | 6.25 | 6.25 | 100.0 |

| Fertilizers and biocides | Compost / manure | ha | 1.0 | 124.0 | 124.0 | 100.0 |

| Total costs for maintenance of the Technology | 327.85 | |||||

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

labour affect the cost, soil type also affects the durability of the tools

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

400.00

Agro-climatic zone

- semi-arid

- arid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Slopes on average: Also gentle

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

- medium (loamy, silty)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility is very low - low

Soil drainage / infiltration is medium

Soil water storage capacity is low - very low

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

- mixed (subsistence/ commercial

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

- average

Level of mechanization:

- manual work

Indicate other relevant characteristics of the land users:

20% of the land users are average wealthy and own 50% of the land.

65% of the land users are poor and own 40% of the land.

15% of the land users are poor and own 10% of the land.

Off-farm income specification: due to frequent failure, farmer embark on other income generating activities such as local brew making hunting charcoal making and provision of cheap labour to successful farmers

Market orientation of production system: Crop performance is poor for subsistence

Level of mechanization: No machinery

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Comments:

harvest of 0-3 bag/acre

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

- individual, not titled

Land use rights:

- communal (organized)

- leased

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Income and costs

farm income

workload

Socio-cultural impacts

community institutions

national institutions

SLM/ land degradation knowledge

Ecological impacts

Water cycle/ runoff

excess water drainage

Soil

soil moisture

soil cover

soil loss

Climate and disaster risk reduction

wind velocity

Other ecological impacts

soil fertility

biodiversity

6.2 Off-site impacts the Technology has shown

reliable and stable stream flows in dry season

downstream flooding

downstream siltation

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

6.5 Adoption of the Technology

- more than 50%

If available, quantify (no. of households and/ or area covered):

400 households covering 85 percent of the area stated (60 percent of all land users)

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 90-100%

Comments:

400 land user families have adopted the Technology without any external material support

Comments on spontaneous adoption: estimates

There is a strong trend towards spontaneous adoption of the Technology

Comments on adoption trend: The spread of this pitting technology has been quite rapid. The latest figures put the number of adopters at just over 300, though apparently it is mainly men who have taken to the system according to estimates. Most of this has occurred since systematic visits were organized by the project.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| same as above |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

ability to harvest rain How can they be sustained / enhanced? construct big contour bunds |

|

ability to store water How can they be sustained / enhanced? ensure no water escapes |

|

ability to enable safe application of fym and compost How can they be sustained / enhanced? use mapambano compost developed by mama Suzana |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| same as above |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| tough job | use of shovels |

| dry spells have negative impacts | increases size of pits after research |

7. References and links

7.2 References to available publications

Title, author, year, ISBN:

Kithinji M., Critchley W. 2001. Farmers' initiatives in land husbandry: Promising technologies for the drier areas of East Africa. RELMA Technical Report series no. 27

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules