Biogas system at household level fed daily with cattle manure [Cambodia]

- Creation:

- Update:

- Compiler: Christoph Kaufmann

- Editor: –

- Reviewers: Deborah Niggli, David Streiff

ប្រពន្ធ័ឡជីវៈឧស្ម័នប្រើសំរាប់គ្រួសារប្រចំាថៃ្ងដោយប្រើលាមកគោ (Khmer)

technologies_1645 - Cambodia

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Khun Lean Hak

kleanghak@yahoo.com

SOFDEC/LAREC, www.sofdec.org

Cambodia

SLM specialist:

Pith Khonhel

khonhel@gmail.com

LAREC

Cambodia

SLM specialist:

Bin Sreytouch

Sreytouchbin@gmail.com

SOFDEC

Cambodia

SLM specialist:

Say Mesa

Saymesa18@gmail.com

SOFDEC

Cambodia

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Society for Community Development in Cambodia (SOFDEC) - CambodiaName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Local Agricultural Research and Extension Centre (LAREC) - Cambodia1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

05/08/2014

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Small-scale biogas systems fed with cow manure and water are implemented in order to supply the household with energy for cooking and lighting, as well as to produce fertilizer.

2.2 Detailed description of the Technology

Description:

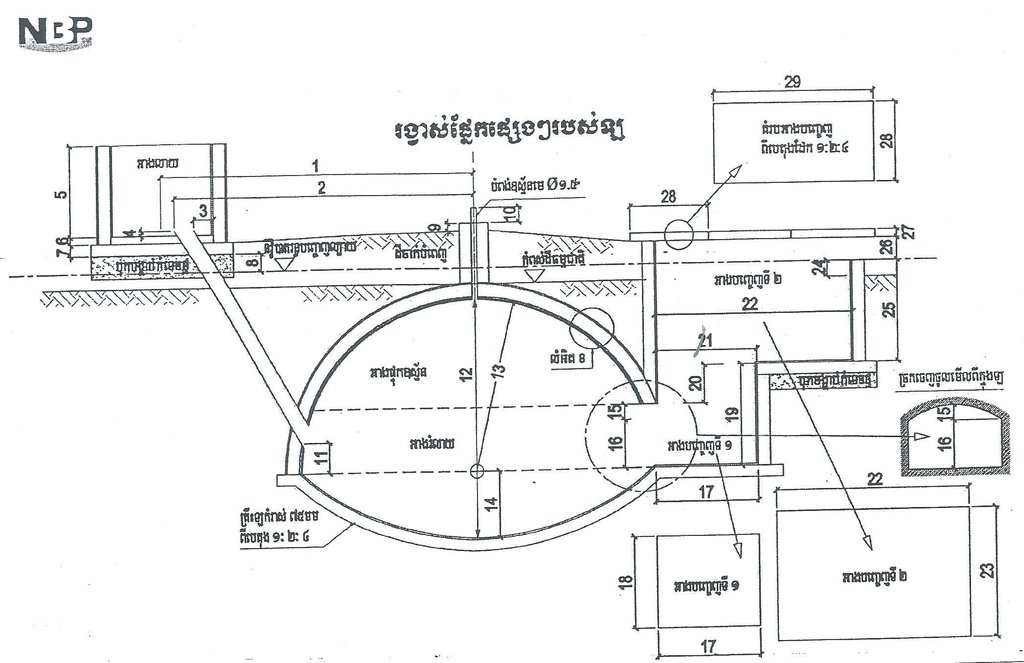

In this case-study, a small-scale biogas system was introduced in order to generate both energy for home consumption and fertilizer. Small-scale biogas systems are implemented in different parts of the world, however the layout thereof varies considerably.

The model used in this case-study consists of different components (cf. technical drawing). First, there is an inlet where the land user puts cow manure mixed with water. On the bottom of the inlet, there is a board which closes the access to the bio-digester situated beneath the inlet. The board can be opened manually by pulling a string. Once the board is open, the fluid components go through a pipe which leads to the bio-digester. In the bio-digester, bacteria transform the organic matter into biogas (mainly methane and CO2) and slurry. At the other end of the digester, there is another pipe (outlet). The outlet is lower than the inlet, and due to the difference in pressure, the slurry is pushed out of the digester. The slurry is dried and applied to the fields two to three times a year with the help of an ox cart. It has similar effects on the plant growth as chemical fertilizer as it does not build up the soil organic matter as much as compost. The biogas, however, is pushed to the pipe situated on top of the digester and can be utilized for domestic uses. The gas is used for cooking and lighting.

The use of biogas allows reducing the expenses on charging batteries for the lighting, as well as reducing the firewood use (usually from deforestation) for cooking. The slurry reduces the expenses on chemical fertilizer in the fields and has the advantage of killing the weed and rice seeds present in the manure and crop residues.

For building the biogas system, there is governmental and NGO support. These two actors finance half of the construction costs. The other half is paid by the land user. Building a biogas system is quite costly, with about 400 $, and not all of the land users in the area can afford paying 50% of its price. However, the costs borne by the land user are paid off within a few years due to reduced expenses on firewood, chemical fertilizer, and charging batteries. The construction itself was undertaken by local companies.

The costs are paid off within a few years due to the reduced expenses on firewood, chemical fertilizer and battery charging.

The analysed area is flat (slope < 2%), tropic (dry and wet season), and the soils are mostly sandy or loamy. The soils contain little organic matter (low soil fertility, acidification, small amount of cattle, area has been deforested a long time ago) and the groundwater table is rather high (1-3 m during the dry season, on the surface during wet season).

Due to climate change, the rainfalls are more erratic, temperatures rise and droughts are more recurrent. Rice is the predominant crop grown in the area, since it serves as staple food (mix subsistence and commercial activities). Rice is often grown in monocultures and harvested once a year. Once the rice is harvested (dry season), the cattle are released to the paddy fields. The cattle is often replaced by hand tractors, which effects the production of manure but allows a higher amount of crop residues on the fields.

As an addition to rice, most land users grow vegetable and fruits in small home gardens (subsistence) and complement their income by producing handicrafts or through off farm income / remittances from family members working in other places. The increasing migration rate (the young generation leaves the villages to work in the cities, garment industry or abroad) results in a decrease of available labour force in the area which has detrimental effects on the agricultural activities. Furthermore, the civil war in the 1970s (Khmer Rouge) led to the loss of agricultural knowledge which different NGOs try to re-establish.

2.3 Photos of the Technology

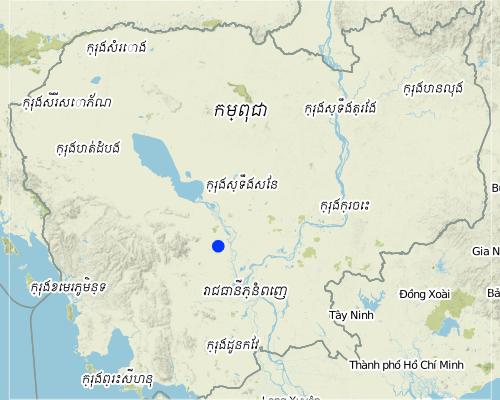

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Cambodia

Region/ State/ Province:

Kampong Chhnang

Further specification of location:

Sre Ouk Samlor Sap/Taing Krasaing/Rolear Pha,er

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

LWS (a Dutch NGO) in joint efforts with specialists from the National Biodigester Program NBP. Implementation in 2012

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Settlements, infrastructure

- Settlements, buildings

- Energy: pipelines, power lines

Comments:

Major land use problems (compiler’s opinion): Lack of organic matter, lack of water retention in soil, irregularity of rainfall, low soil fertility (sandy soil), monocultures, bare soil during dry season, ploughing.

Major land use problems (land users’ perception): Low soil fertility, lack of water.

Livestock is grazing on crop residues

Constraints of settlement / urban

Constraints of infrastructure network (roads, railways, pipe lines, power lines)

3.3 Further information about land use

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 210, Longest growing period from month to month: June-December

3.4 SLM group to which the Technology belongs

- energy efficiency technologies

3.5 Spread of the Technology

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, indicate approximate area covered:

- 0.1-1 km2

Comments:

There are only 4 households in this village which apply the technology (lack of money and/or cattle). However, similar Technologies are introduced in other provinces – yet it is difficult to estimate the area covered. Estimation for this village.

3.6 SLM measures comprising the Technology

structural measures

- S11: Others

management measures

- M6: Waste management (recycling, re-use or reduce)

Comments:

Main measures: management measures

Secondary measures: structural measures

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

- Ca: acidification

biological degradation

- Bs: quality and species composition/ diversity decline

Comments:

Main causes of degradation: soil management (Ploughing, soil is left bare for several weeks), crop management (annual, perennial, tree/shrub) (Rice monoculture (rice as staple crop)), change of seasonal rainfall (More erratic beginning of wet season), droughts (On dry soil, rice cannot be planted and if already planted, rice cannot grow), labour availability (High migration rates from the villages to garment industry, cities or abroad, influence agricultural activities (e.g. broadcasting instead of transplanting of rice seedlings)), education, access to knowledge and support services (Khmer Rouge regime in the 1970s, a lot of knowledge got lost)

Secondary causes of degradation: over-exploitation of vegetation for domestic use (Rice straw is removed for different domestic uses (cattle, mushroom cultivation, etc.)), overgrazing (Cattle eats rice straw left after harvest, less organic matter on the field, grazing is not managed), change in temperature (More hot days), Heavy / extreme rainfall (intensity/amounts), land tenure (Some incidents of land grabbing, land use rights not clear, corruption), poverty / wealth

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

Biodigester. Inlet: top left; gas outlet: top centre; digestion chambre: centre; and outlet: right. For the comlete building instructions contact the NBP.

Technical knowledge required for field staff / advisors: high (The most challenging part is the construction of the construction of the Biodigester.)

Technical knowledge required for land users: low

Main technical functions: increase in nutrient availability (supply, recycling,…)

Secondary technical functions: increase in organic matter

Structural measure: Biodigester. Round shape. Tiles and concrete.

Width of ditches/pits/dams (m): 4 m^3

Structural measure: Connecting pipes made of plastic

Construction material (concrete): Tiles are covered in concrete.

Construction material (other): The most challenging part is the construction of the Biodigester.

Other type of management: Change of energy supply system for home consumption.

4.3 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Riel

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

4000.0

Indicate average wage cost of hired labour per day:

5.00

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Construction of the biodigester by external experts. The land user did not help with the construction, he only paid 200 US$. The other 200 US$ were paid by the National Biodigester Program. | Structural | Dry season, when water table is low. |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Construction material | Construction of biodigester | 1.0 | 400.0 | 400.0 | 50.0 | |

| Total costs for establishment of the Technology | 400.0 | |||||

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Add manure and water to the inlet | Management | once per day all year round |

| 2. | Collect residuals from biodigester, spread it out and let it dry, and finally put it on the field. | Management | 3 times/year |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | 1.0 | 121.5 | 121.5 | 100.0 | |

| Total costs for maintenance of the Technology | 121.5 | |||||

Comments:

Machinery/ tools: Cart to bring residues from the biodigester onto the fields.

The costs were calculated for 1 biodigester with a capacity of 4 m3.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The most costly part of this Technology is the construction of the biodigester. Once the system is installed, the costs borne by the land user are low. Also, the land user can save money since he doesn’t need to buy firewood any more.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

1486.45 mm 2013 in Kampong Chhnang

Agro-climatic zone

- sub-humid

27° to 35°C, 1486.45 mm 2013 in Kampong Chhnang

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

poor/ none

Water quality (untreated):

poor drinking water (treatment required)

Comments and further specifications on water quality and quantity:

Ground water tabel and availability of surface water data during dry seasons. People use water for drinking after filtering or boiling.

5.5 Biodiversity

Species diversity:

- low

Comments and further specifications on biodiversity:

Only degraded forests are in the area.

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Semi-nomadic

Market orientation of production system:

- mixed (subsistence/ commercial

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- rich

Individuals or groups:

- individual/ household

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly Leaders / privileged

Population density: 10-50 persons/km2

Annual population growth: 0.5% - 1%

Off-farm income specification: Handicraft, remittances and factory work.

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

- individual, not titled

Land use rights:

- communal (organized)

- individual

Water use rights:

- open access (unorganized)

Comments:

Land ownership is very complex. Most of the land belongs officially to the government, yet many land users hold a paper confirming they applied for a land title – but de iure, this paper is worthless.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

Dried residues are put in the garden (cucumber, pumpkin, watermelon) which increases nutrient availability.

energy generation

Income and costs

expenses on agricultural inputs

Comments/ specify:

He saves 50 $ on chemical fertilizer per year.

Socio-cultural impacts

health situation

Comments/ specify:

No smoke from open fire.

Contribution to human well-being

Comments/ specify:

On the long term livelihood is improved, because he saves over 60 $ per year in firewood and battery charging for light, as well as 50 $ for chemical fertilizer.

Ecological impacts

Water cycle/ runoff

water quality

Comments/ specify:

Pollution of groundwater due to washing out of nutrients.

Soil

soil organic matter/ below ground C

Comments/ specify:

Most of the carbon is transformed into methane, not available as organic matter.

Other ecological impacts

reduced weed seeds

Comments/ specify:

Compost usually not completely decomposed, as well as raw manure, contain lots of weed seeds.

energy generation (eg hydro, bio)

Comments/ specify:

Before the installation of the biogas system, the land user bought firewood.

deforestation for firewood

6.2 Off-site impacts the Technology has shown

groundwater/ river pollution

Comments/ specify:

Sludge is left to dry outside, nutrients washed out into groundwater. Not measurable.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- more than 50%

If available, quantify (no. of households and/ or area covered):

100% or 4 land user families

Comments:

100% of land user families have adopted the Technology with external material support

4 land user families have adopted the Technology with external material support

The farmers can ask the National Biodigester Program for subsidies, but need to pay half of it on their own. As the farmers often lack money and need at least 3 - 4 heads of cattle to produce enough manure while they switch more and more to hand tractors, not many farmers are building new biogas digesters.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Fertilizer production (sludge). |

| Saves money and time on the cooking fuel (previously wood) and electricity (charging batteries) for the light. |

| No weed seeds in the sludge compared to compost and raw manure if used as fertilizer. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Less deforestation for firewood. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The residue does not improve the soil as much as compost. | Make compost in addition to biogas to enhance the soil organic matter. |

| The building costs are prohibitive | Increase subsidies from state or NGOs. |

| At least 3-4 heads of cattle or 4-5 pigs have to be kept to produce enough manure. | Diversify production with different animals. |

| Work has to be done each day to produce biogas. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Overgrazing could become a problem as more cattle needs to be kept. | Add slurry as a liquid fertilizer |

| Part of nitrogen is volatilized during the drying of the sludge. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

7.2 References to available publications

Title, author, year, ISBN:

NBP National Biodigester Program

Available from where? Costs?

www.nbp.org.kh

Title, author, year, ISBN:

Lam et al. 2009. Domestic Biogas Compact Course. University of Oldenburg.

Available from where? Costs?

http://www.nbp.org.kh/publication/study_report/2_domestic_biogas%20.pdf

Title, author, year, ISBN:

Gurung. 2009. Review of Literature on Effects of Slurry Use on Crop production. The Biogas Support Program

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules