Using slurry from biodigester for soil improvement [Cambodia]

- Creation:

- Update:

- Compiler: Nary Lay

- Editors: Sophea Tim, SOBEN KIM, Navin Chea

- Reviewers: SO Than, Ursula Gaemperli

biodigester

technologies_2137 - Cambodia

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Acting Chief of Preaek Prasab Agricultural, Forestry and Fisheries district:

Official of Chetr Borie Agricultural, Forestry and Fisheries district :

Ly Saravuth

(+855) 89 796 786 / NA

saravuthly123@gmail.com / NA

Office of Chetr Borie Agriculture, Forestry and Fisheries District

Khsa village, Da commune, Chetr Borie district, Kratie province.

Cambodia

land user:

Sum Sok

(+855) 71 420 33 13 / NA

NA / NA

Farmer

Kamboa village, Kou Loab commune, Chetr Borie District, Kratie province

Cambodia

Chief of Sambour Agricultural, Forestry and Fisheries district:

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Royal University of Agriculture (RUA) - Cambodia1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

10/04/2017

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

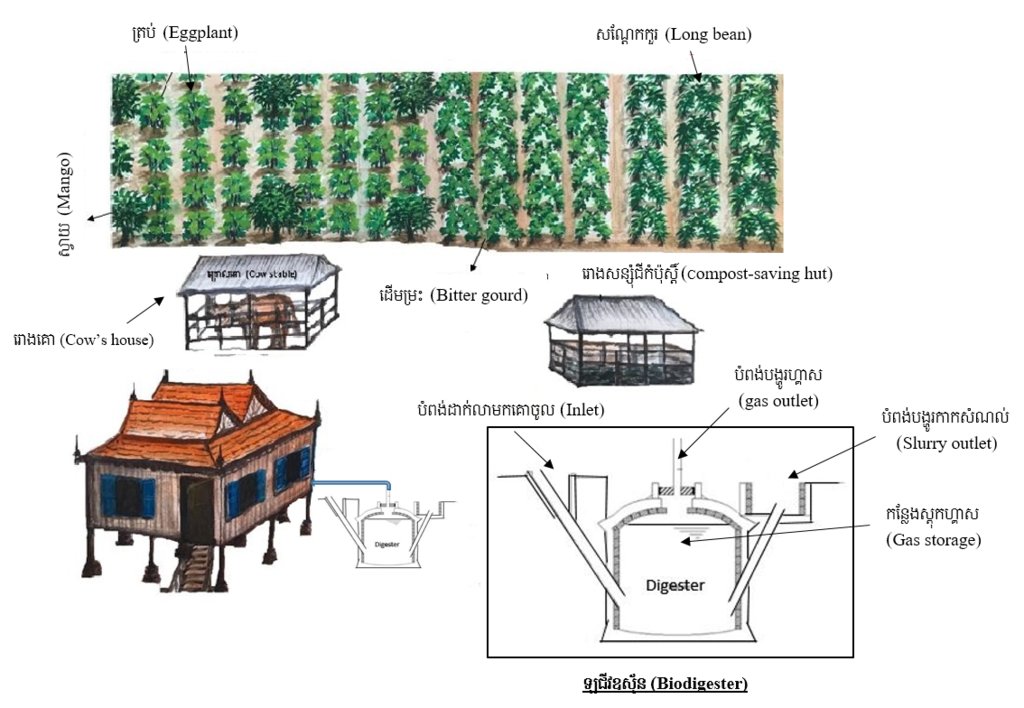

Biodigester slurry sourced from cow manure is used as an important natural fertilizer for the cultivation of crops. It is a form of organic fertilizer that is thoroughly decomposed, does not have an awful smell, or contain living weed seeds, fungi and other viruses. It can also be used immediately after the slurry flows out of the biodigester tank. Such fertilizer helps to improve the soil quality in the long-term due to the rich organic matter that it contains which slowly decomposes to plant nutrients.

2.2 Detailed description of the Technology

Description:

There are many kinds of biodigesters and the one used in this technology is a 5000 liter plastic cylinder. It was installed by placing part of the tank into the ground and setting up an inlet-outlet pipe as well as a gas pipe system. The whole installation process takes around a day to complete. In order to produce gas initially the biodigester needs about 120 buckets (around 2000 kg) of fresh cow manure and 120 buckets (1200 liters) of water, which then needs to be kept for one week so that it can produce gas and slurry as fertilizer. After that the farmer has to add one bucket (around 20 kg) of fresh cow manure and one bucket (20 liters) of water every day in order to maintain the continuous production of gas and slurry. As a result, the farmer’s family has gas from the biodigester which provides sufficient energy for cooking. In this way they are able to save time which is otherwise spent collecting fuel-wood and it reduces their firewood consumption by around 2190 kg per year. The fresh cow manure for the biodigester should be free from rubbish and not contain small gravel because this blocks the inlet /outlet of the biodigester tank.

In addition, to be able to use the gas for cooking and lighting, the farmer also has the opportunity of using the slurry from the biodigester as fertilizer for all kinds of crops, including bitter gourds, eggplants, mangos, yard long beans, rice, bamboo shoots and other supplementary crops. The slurry from the biodigester can be applied as fertilizer either in a liquid, a semi-dry or a dry form. The slurry can be applied to the crops directly or compost can be made by mixing it with other degradable materials such as woody herb, rice straw and other green leaves. This practice will increase the quantity of the fertilizer because the slurry from bioidigester helps to accelerate the decomposition process and it also produces a higher quality compost.

The slurry from biodigester improves soil aggregates and fertility for a longer period than chemical fertilizers. The slurry contains a lot of nutrients specially nitrogen, phosphorus and potassium that are necessary for plants, and it does not have an awful smell, or contain weed seeds and parasites. The nutrients are in a chemical form which can easily be absorbed by plants, and it contains vitamin B12 which stimulates the growth of earth worms. The use of slurry enables the growth of various microorganisms and besides earth worms, other useful animals such as frogs and soil-insects, thereby maintaining a natural balance of the environment. The fertilizer enhances the growth of crops, builds resistance to disease, and does not affect the soil and human health. For poorer quality soil, the slurry or compost improves both the physical and biological conditions of the soil. It improves the nutrient content including macronutrients and micronutrients, and also helps to keep soil aggregates and moisture.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Cambodia

Region/ State/ Province:

Kamboa village, Kouleap commune, Chitrborie district, Kratie province.

Further specification of location:

Rural

Map

×2.6 Date of implementation

Indicate year of implementation:

2016

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

National Biodigester Programme

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- conserve ecosystem

- preserve/ improve biodiversity

- mitigate climate change and its impacts

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Perennial (non-woody) cropping

- Tree and shrub cropping

Main crops (cash and food crops):

Rice, sugar cane, banana, eggplant, bitter gourd, yard long bean, mango and other vegetable.

If land use has changed due to the implementation of the Technology, indicate land use before implementation of the Technology:

This land was previously degraded forest land.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

For irrigating the crops the farmer uses groundwater from the well .

Number of growing seasons per year:

- 3

Specify:

Cultivation of vegetable all year around

Livestock density (if relevant):

Raising of 19 cows to supply manure for the biodigester and also around 100 chicken

3.4 SLM group to which the Technology belongs

- integrated crop-livestock management

- energy efficiency technologies

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

National Biodigester Programme installed such biodigester at 6 families in Kouloap commune.

3.6 SLM measures comprising the Technology

management measures

- M6: Waste management (recycling, re-use or reduce)

3.7 Main types of land degradation addressed by the Technology

physical soil deterioration

- Pu: loss of bio-productive function due to other activities

biological degradation

- Bs: quality and species composition/ diversity decline

- Bl: loss of soil life

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

Biodigester tank is made of a plastic tank of 5,000 liter volume. The biodigester structure has three pipes: inlet, gas pipe and outlet. The inlet is for pouring the mixed fresh cow manure into the biodigester tank, while outlet is where the slurry comes out. The pipe is for delivering gas from the biodirester to the end use places. The tank is buried at one-third of the height into the ground. On a daily basis, it needs around 20kg cow manure mixed with 20 litres of water, putting into the tank. There is a hut (3×3 meters sides with 1.6 meters high) for storing the slurry and making compost. The roof is made of zinc at 0,5 meters height above the wall. Bio-digester fertilizers are used on many types of crops in the fields. It can produce around 4 cubic meters of gas, offsetting the use of around 2,190 kg of firewood per year.

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Biodigester

other/ national currency (specify):

Riel

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

4000.0

Indicate average wage cost of hired labour per day:

25000 riel

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Dig soil | Management | May |

| 2. | Put biodigester | Management | May |

| 3. | Prepare pipe system | Management | May |

| 4. | Install | Management | May |

| 5. | Add cow manure | Management | May |

4.5 Costs and inputs needed for establishment

If possible, break down the costs of establishment according to the following table, specifying inputs and costs per input. If you are unable to break down the costs, give an estimation of the total costs of establishing the Technology:

4000000.0

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | Biodigester | set | 1.0 | 4000000.0 | 4000000.0 | 20.0 |

| Total costs for establishment of the Technology | 4000000.0 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Support from National Biodigester Programme (NBP)

Comments:

80% of the total cost was subsidised by the NBP.

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Clean drainage pipes | Management | every day |

| 2. | Putting cow manure | Management | every day |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Cleaning by themself | Hour | 30.42 | 3124.0 | 95032.08 | 100.0 |

| Fertilizers and biocides | Cow manure | Kg | 20.0 | 1200.0 | 24000.0 | 100.0 |

| Fertilizers and biocides | Water | Liter | 20.0 | 200.0 | 4000.0 | 100.0 |

| Total costs for maintenance of the Technology | 123032.08 | |||||

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The cost of the plastic tank and the enough cows to producing sufficient slurry for the manure production.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1138.20

Specifications/ comments on rainfall:

The average annual rainfall in 2015 is 1138.2 mm, in 2014 is 1696.5 mm, in 2013 is 1661.8 mm.

Indicate the name of the reference meteorological station considered:

Ministry of Water Resources and Meteorology (2015)

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- fine/ heavy (clay)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

pH: 5.5

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

good

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

Comments and further specifications on water quality and quantity:

Groundwater from well is used for irrigation and ensures supply for the whole year.

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- commercial/ market

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- men

Age of land users:

- middle-aged

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

Comments:

He owns 3 hectares of rice field, 0.15 hectare of borrowed land and 1 hectare (forest) of uncultivated land.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

150 kg per month

Quantity after SLM:

450 kg per month

crop quality

Comments/ specify:

Biodigester slurry is a rich-nutrient natural fertilizer and the produced crop is not chemically contaminated.

animal production

Quantity before SLM:

10 Cows

Quantity after SLM:

19 cows

Comments/ specify:

As cow manure is needed for the biodigester to produce enough gas and compost, the herd size had to be increased.

risk of production failure

Comments/ specify:

As the farmer was able to scale up the plant variety by using slurry from biodigester the risk of production shortfall for one crop can be compensated by the other crops.

product diversity

Comments/ specify:

As the slurry from biodigester matches to all sorts of plants, the farmer was able to scale up the product diversity.

land management

Quantity before SLM:

Use chemical fertilizer

Quantity after SLM:

Use compost fertilizer

Comments/ specify:

Fertilizer now is produced on farm in a very short time and therefore farmer doesn’t have to run after manure.

energy generation

Comments/ specify:

Before the farmer family was forced to look for huge amounts of fire wood (over 1,290 kg per year) in the surrounding area. Now, as side effect of the compost production gas can be produced for cooking.

Income and costs

expenses on agricultural inputs

Comments/ specify:

No chemical fertilizer has to be bought.

farm income

Quantity before SLM:

15 %

Quantity after SLM:

45 %

Comments/ specify:

The farmer now has diversified productions from the various crops due to the improved soil quality, thus, the household income increased substatially.

workload

Comments/ specify:

Stop going to the forest to collect fire wood.

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

The farmer now have enough and healthy food for the whole year and surplus for selling.

health situation

Comments/ specify:

Compared to former time, the family is less sick which is closely associated healthier food production and the and the cleaner air during cooking.

SLM/ land degradation knowledge

Comments/ specify:

The farmer participated in training on compost and vegetable growing including some field visits.

Ecological impacts

Water cycle/ runoff

evaporation

Comments/ specify:

Due to the better availability of fertilizer, the farmer grows more crops on his land during the whole year. In cosequence of this, the evaporation is slightly reduced. Also, higher plants such as mango trees provide more shade to the land.

Soil

soil moisture

Comments/ specify:

The increase in organic matter and the better soil cover by plants improved the soil moisture slightly.

soil cover

Comments/ specify:

During all seasons the soil is now covered by plants.

soil organic matter/ below ground C

Comments/ specify:

Soil rich in nutrients due to the frequent compost application

Biodiversity: vegetation, animals

plant diversity

Comments/ specify:

Due to beneficial soil conditions, plant diversity increased.

animal diversity

Comments/ specify:

Increase in number of frog, worm, and earthworm

beneficial species

Comments/ specify:

More frogs, worms, and earthworms

pest/ disease control

Comments/ specify:

There are still some insects damaging plant leaves, but compared to before the number has decreased due to the healthier soil conditions.

6.2 Off-site impacts the Technology has shown

impact of greenhouse gases

Comments/ specify:

No burn of firewood for cooking and preservation of forests for carbon sequestration

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | moderately | |

| seasonal temperature | wet/ rainy season | increase | moderately |

| annual rainfall | increase | moderately | |

| seasonal rainfall | wet/ rainy season | increase | moderately |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Biological disasters

| How does the Technology cope with it? | |

|---|---|

| epidemic diseases | moderately |

| insect/ worm infestation | moderately |

Comments:

When watjer is hotter soils keep moisture better and does not dry very fast.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

Comments:

No money was needed to repair the biodigester system untill now.

6.5 Adoption of the Technology

- 1-10%

If available, quantify (no. of households and/ or area covered):

Six households have been supported to get the biodigester by the NBP.

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

Many farmers want to install the biodigester, but has difficulty with the expenses.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Manufacture fertilizer by himself |

| Can be applied directly to the crop which not results in its putrefy, unlike fresh cow manure which can lead to the putrescence of crops and the growth of a lot of grass. |

| Saving of 2190 kg of firewood per year. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Helps to improve the soil quality. |

| Reduces negative environmental effects. |

| Reduces daily costs. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| A biodigester is expensive | National biodigester programme to support |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| A biodigester is expensive | Need a supporting fund from relevant institutions. |

| Need of enough cow manure | Promote livestock raising, especially cows. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

1 persons

- interviews with land users

1 person

- compilation from reports and other existing documentation

National Biodigester Programme

7.2 References to available publications

Title, author, year, ISBN:

National Biodigester Programme (2013): Farmers Handbook on Management and Use of waste biodigester. Public on January 10th (in khmer)

Available from where? Costs?

Ministry of Agriculture, Forestry and Fisheries

7.3 Links to relevant information which is available online

Title/ description:

National Biodigester Program.(2015). National Biodigester Program in CAMBODIA.Ministry of Agriculture, Forestry and Fisheries (in Khmer).retrieve 15/01/2018 from

URL:

www.nbp.org.kh

Title/ description:

Savbory.O.(2014). Mistry announce farmer to use biodigester for get profit.Radio Free Asia (in Khmer). retrieved on 15/01/2018 from

URL:

www.rfa.org/khmer/news/environment/bio-mass-oven-03062014034222.html

Title/ description:

Mansvelt,.R.&Sras,.P.&Pino,.M.(2012).Biodigester User Survey 2012.National Biodigester Programme.retrieved 15/01/2018 from

URL:

https://www.google.com/search?q=Biogas+user+survey+-+Cambodia+2009-2010+&ie=utf-8&oe=utf-8&client=firefox-b-ab

Title/ description:

Mansvelt.R.(2011).Biodigester User Survey 2009-2010. National Biodigester Programme.retrieved 15/01/2018 from

URL:

https://www.google.com/search?q=Biogas+user+survey+-+Cambodia+2009-2010+&ie=utf-8&oe=utf-8&client=firefox-b-ab

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules