Using dry compost on paddy rice fields [Cambodia]

- Creation:

- Update:

- Compiler: Navin Chea

- Editors: Sophea Tim, Sok Pheak

- Reviewers: Nimul CHUN, Ursula Gaemperli

Dry composting

technologies_3215 - Cambodia

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Morm Mok

(+855) 92 596 851

n/a

Land user

Vat Chas village, Baray commune, Prey Chhor district, Kampong Cham province.

Cambodia

Chief of District Office of Agriculture, Forestry and Fisheries, Prey Chhor:

Oem Lieng Song

(+855) 89 755 975

n/a

District Office of Agriculture, Forestry and Fisheries, Prey Chhor

Prey Toteng vilage, Chrey Vien commune, Prey Chhor district, Kampong Cham province.

Cambodia

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Royal University of Agriculture (RUA) - Cambodia1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

08/05/2017

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

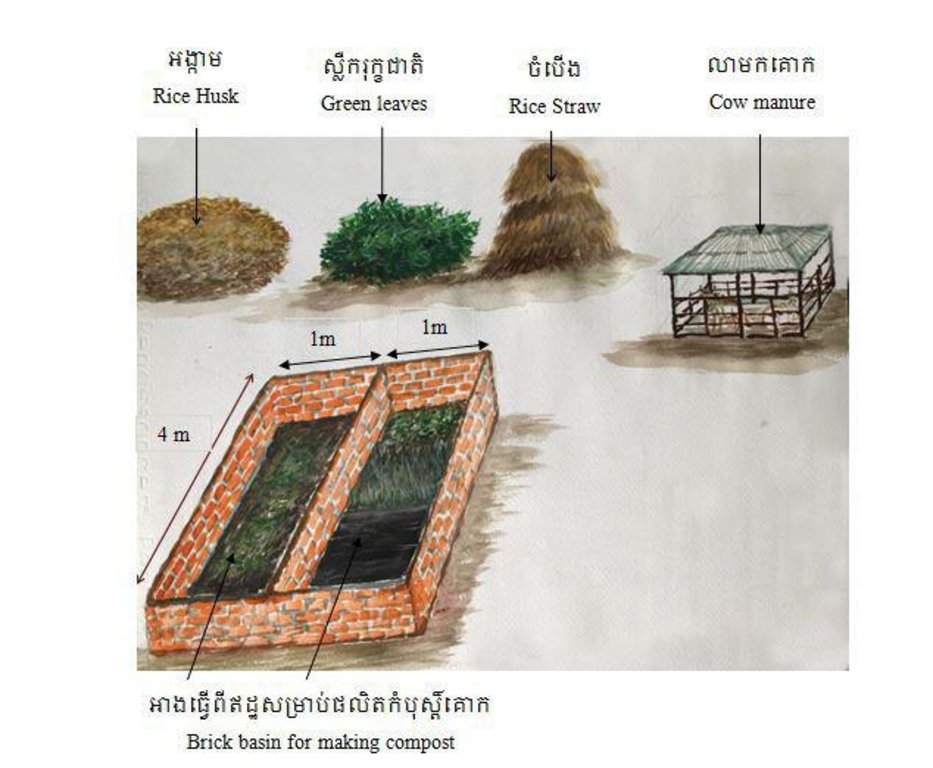

Dry compost is made from raw materials of cow manure, rice straw, rice husks, ash, leaves, waste from kitchen and water for application on paddy rice field to improveof soil quality and reduce chemical fertilizers.

2.2 Detailed description of the Technology

Description:

Compost is a natural fertilizer derived from decayed organic materials, which helps plants grow better than using fresh manure or fresh vegetable residues because they are made up of many organic substances. Farmer could make compost within different periods, short term, medium term and long term. Compost can already be done in 14 to 18 days and it can be used, but the average maturation is 3-4 months and the long term , it can be used after 5 to 6 months (CEDAC, 2015).

Compost is made of manure (cow, buffaloes, pigs, poultry), household waste, fresh plant leaves (woody herb, water hyacinth, water lettuce, vegetable or fruit), etc. The compost brings significant benefits, such as: It provides quick nutrients to plants when compared with fresh manure or unburnt fertilizers. In addition, compost fertilizers bring many microorganisms to the soil, and these organisms help soil fertility. It doesn't exist any plants seed or weed, virus, disease on crop because most of them are killed while the fertilizer is decaying (CEDAC, 2015,YouTube, 2016).

Mr. Mam Mok, the examined farmer of this case study has been practicing this kind of fertilizer since 2008. His compost is made up of ingredients such as rice straw, cow manure, leaves, rice husks, biochar, kitchen waste, water etc. He uses dry compost mainly for his paddy rice fields.

The main purposes of making compost are to increase the rice yield and to get healthier produced rice (reduction in chemical fertilizer). Before he used dry compost his rice yield reached an amount of 4 tons per hectare by using a high amount of Urea (5 bags per hectare), now, though, his yield is about 5 to 6 tons per hectare. In addition, chemical fertilizer has been reduced to 1 to 2 bags per hectare. This means that the application of dry compost reduces as well the expenditure for chemical fertilizers. Another advantage is that the land user gets his manure on-site without spending money, as the most part of material can be found for free on his farm or nearby.

It is a very good SLM technology to improve soil fertility. The application of dry compost avoids compaction, increases the organic matter in soil, boosts the general activity of micro-organisms, and consequently stimulates the growth of rice plants. Then again, there are also some constraints as the amount of compost is not sufficient to feed the whole area of 1.30 hectares. Therefore, every year the farmer spreads the compost only on about an area of 0.50-0.60 hectares by shifting every year the application area. Moreover, the manufacturing requires labor force, which in the family of Mr. Mam Mok is rather decreasing. The duty consists e.g. of collecting raw material and the daily control over compost stage during the maturation process. At any time he has to control if water has to be added to the raw material. After three month he has to transfer the whole compost, partly decayed, from one basin to another, where final maturation takes place. However, the farmer is satisfied with the technology and because of multiple benefits he does not intend to give it up.

Before getting started with compost manufacturing, two compost basins (4 meter in length, 1 m in wide, 1 m in depth) have to be constructed. They are made of bricks, which guarantee a long life cycle. During the rainy season, the farmer uses a tent to cover the basins.

Following steps are necessary to get dry compost: Step 1: A layer of 30 cm of rice straw squashed and mixed with rice husks has to be filled on the bottom of the first basin. After, this mixture needs to be watered sufficiently. Step 3: 20 cm of cow manure has to be put over the first layer. After this, ash from rice husks or from the kitchen waste has to be added. Then it should be watered again. Last step is to bring the already pre-shredded woody herb or leaves (30 cm) on the previous layer. Preparation of layers takes place at the same time. It can be done at any time given, depending nothing but on available raw material and the labor force supporting the manufacturing.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Cambodia

Region/ State/ Province:

Vat Chas village, Chrey Vien commune

Map

×2.6 Date of implementation

Indicate year of implementation:

2008

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

The technique of making compost is learned through ERECON's project and the practice is continued after the project completed.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- conserve ecosystem

- adapt to climate change/ extremes and its impacts

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Main crops (cash and food crops):

Paddy rice

If land use has changed due to the implementation of the Technology, indicate land use before implementation of the Technology:

Previously high amount of chemical fertilizer was used together with a little of cow manure.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Number of growing seasons per year:

- 1

Livestock density (if relevant):

The farmer has 5 cows.

3.4 SLM group to which the Technology belongs

- integrated soil fertility management

- waste management/ waste water management

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

physical soil deterioration

- Pc: compaction

biological degradation

- Bl: loss of soil life

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

There are twin compost basins. Each basin is 4 square meters (1 meter width and 4 meters length ) for making compost, with 1 meter depth for both basins. There are four holes at the lower parts of the walls. The basins are made of brick with concrete, built closed to the house. The raw material for making compost includes cow manure, leaves, rice husk, ash wash from house and water.

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

other/ national currency (specify):

Riel

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

4000.0

Indicate average wage cost of hired labour per day:

25000 KHR

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Constructing compost basins | Structural | May |

| 2. | Collecting raw materials | Management | August |

| 3. | Applying ash of rice husk | Management | August |

Comments:

For making compost, plastic stuff is excluded or need to be taken off, otherwise it affects the soil.

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Construction of compost basins | Day | 4.0 | 15000.0 | 60000.0 | 100.0 |

| Fertilizers and biocides | Cow manure | Two wheel tractor | 5.0 | 300000.0 | 1500000.0 | 100.0 |

| Construction material | Brick | piece | 900.0 | 140.0 | 126000.0 | |

| Construction material | Cement | bag | 6.0 | 20000.0 | 120000.0 | |

| Construction material | Sand | cubic meter | 2.0 | 40000.0 | 80000.0 | |

| Construction material | Atarpaulin | set | 1.0 | 40000.0 | 40000.0 | |

| Construction material | Hoe | piece | 1.0 | 15000.0 | 15000.0 | 100.0 |

| Construction material | Handled bansket | pairs | 1.0 | 4000.0 | 4000.0 | |

| Construction material | Big knife | piece | 1.0 | 15000.0 | 15000.0 | 100.0 |

| Construction material | Ax | piece | 1.0 | 10000.0 | 10000.0 | 100.0 |

| Total costs for establishment of the Technology | 1970000.0 | |||||

Comments:

ERECON supported the construction of the twin compost basins during the project phase. And the farmers spent on the composting materials. After the project was finished, farmers adopte it by no external support.

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Watering (self-implemented) | Management | Dry season |

| 2. | Transfer from one composting basin to another when it is decompose | Management | Every two moths or threes months and need to control. |

| 3. | Add more compositing materials | Management | Once per 3 months |

Comments:

It is possible to produce compost 4 times per year, if there is enough labor.

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

If possible, break down the costs of maintenance according to the following table, specifying inputs and costs per input. If you are unable to break down the costs, give an estimation of the total costs of maintaining the Technology:

200000.0

Comments:

Farmer do not expend on hiring labor for maintenance. He does it by himself. Thus, it is difficult to calculate the cost.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The farmer is not in the situation to pay for external manpower, which means working hard by himself. Another financial constraint consists in bringing up enough money to keep an adequate amount of cows to provide sufficient manure for compost manufacturing.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1095.30

Specifications/ comments on rainfall:

The annual rainfall is 1095.3 mm in 2015, 1322.1 mm in 2014, and 1466.9 mm in 2013.

Indicate the name of the reference meteorological station considered:

Ministry of Water Resources and Meteorology (2015)

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil depth: at 3 meters it is white and black rock.

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

good

Water quality (untreated):

poor drinking water (treatment required)

Is water salinity a problem?

No

Is flooding of the area occurring?

Yes

Regularity:

episodically

Comments and further specifications on water quality and quantity:

Water has to be filtered and boiled befor being safe to drink.

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- men

Age of land users:

- elderly

Indicate other relevant characteristics of the land users:

The farmer is 66 years old.

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

Comments:

Own paddy field is 0.70 hectare, and the rental paddy field is 0.80 hectare.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

- Rental land

Land use rights:

- leased

- individual

Water use rights:

- open access (unorganized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

4 tons/hectare

Quantity after SLM:

5-6 tons/hectare

crop quality

Quantity before SLM:

40%

Quantity after SLM:

80%

Comments/ specify:

Good health of crop, when compost was used and soil moisture was improved.

risk of production failure

Comments/ specify:

The production failure has been reduced because he could produce better crop quality which low input of chemical fertilizer and by meeting the high market demand. His rice which cultivation by using compost can be selled at high prices. For example: Phkar Romdul Rice Variety could be sold at the higher price of 1500 Riel/kg, but if he use much of chemical fertilizer, he can sell it only about for 1000 Riel/kg.

Income and costs

expenses on agricultural inputs

Comments/ specify:

Raw materials such as cow manure, rice straw, ash are collected in his own farm, and other materials could be found in the region without expense of money.

farm income

Comments/ specify:

Because of the significant higher yield.

workload

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Because of better rice yield.

health situation

Comments/ specify:

The better crop quality with low input of chemical fertilizer which is good for the health.

SLM/ land degradation knowledge

Comments/ specify:

How to produces compost for reduction of soil degradation. The soil gets less compact and and microorganism in the soil such as earthworm incrases .

Ecological impacts

Water cycle/ runoff

water quantity

water quality

Comments/ specify:

Less chemical fertilizer led to a positiv impact on water quality.

Soil

soil moisture

Comments/ specify:

The farmer - after using the compost - noticed it when he worked the soil.

soil crusting/ sealing

Comments/ specify:

Improved soil texture and soil structure.

soil compaction

Comments/ specify:

As microorganisms activity could be rised, the soil got less compact

nutrient cycling/ recharge

Comments/ specify:

Compost is rich of earthworm.

soil organic matter/ below ground C

Comments/ specify:

Increase soil organism to the soil such as earthworm, snails, frog, ant, spiders, termites etc.

Biodiversity: vegetation, animals

plant diversity

Comments/ specify:

The dry compost provides benefit to every rice species. For example: Growing Phkar Rumduol rice variety or Raiang Chey, the crop are good and get high yield.

beneficial species

Comments/ specify:

Increase such as earthworms, snail , ant , termites etc.

6.2 Off-site impacts the Technology has shown

damage on neighbours' fields

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well | |

| annual rainfall | decrease | moderately | |

| seasonal rainfall | wet/ rainy season | increase | well |

Climate-related extremes (disasters)

Biological disasters

| How does the Technology cope with it? | |

|---|---|

| epidemic diseases | moderately |

| insect/ worm infestation | moderately |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- 10-50%

If available, quantify (no. of households and/ or area covered):

There are 15 families practicing this technology in the village.

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 10-50%

Comments:

There are 15 families practicing the making of compost which support by ERECON. ERECON supported the construction of the twin compost basins. And the farmers spent on the composting materials.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Yes

other (specify):

Improve soil fertiity

Specify adaptation of the Technology (design, material/ species, etc.):

15 families practices this technology supported by ERECON, however even if the project is finished, the farmers still practice this technology.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| The soil is less compact, because of the improvement ofsoil texture. |

| Reduction in the amount of chemical fertilizer. |

|

Raw materials for composting, which can be found in the village |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Compost provides microorganisms tothe soil, which makes it less compact and easier for the plants to absorb the nutrients. |

| Reduction in expenditure on chemical fertilizers, which improves the farmer’s livelihood and enables him to use a safer product. |

| The farmer has his own cows, rice straw, rice husks and other materials which can be found in the region without need to spend money. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| A lack of labor for compost processing in order to complete tasks such as finding adequate material. | step-by-step |

| If one does not work hard on this compost, it will not get ready to use. | Check and take care of the composting process. |

| Due to rain water the compost gets to much moisture some times. | Placing a plastic tarp sheet over the top. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| It requires a lot of labor and time while the family members who were able to assist decreased in number. | Work hard and be patient. |

| Making compost also requires proper training because if compost is produced by the farmers themselves without having received instructions or they have learned it from other farmers it might be not of a very high quality. | Promote training or on-farm practices |

| Lack of adequate amount of compost for all rice fields. | Rotate application of compost on rice fields. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

Five locations

- interviews with land users

One person

- interviews with SLM specialists/ experts

Two persons

- compilation from reports and other existing documentation

7.2 References to available publications

Title, author, year, ISBN:

CEDAC. (2015). Kit of simple Agriculture Technologies. Phnom Penh.

Available from where? Costs?

Cambodian Center for Study and Development in Agriculture (CEDAC). 10000 Riels

7.3 Links to relevant information which is available online

Title/ description:

Video. Compost fertilizer, Cambodia. June 6, 2017

URL:

https://video.search.yahoo.com/search/video;_ylt=A0LEVzNzS.BZYvMAdaJXNyoA;_ylu=X3oDMTEyNWNiaW4yBGNvbG8DYmYxBHBvcwMxBHZ0aWQDQjI5NDRfMQRzZWMDc2M-?p=Making+dry+compost+in+cambodia&fr=tightropetb#action=view&id=4&vid=62cb521e7ee9d4cda885eb335043bb32

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules