Sub-Sarface Dams (SSD) [Kenya]

- Creation:

- Update:

- Compiler: Guyo Roba

- Editor: –

- Reviewer: Rima Mekdaschi Studer

technologies_3340 - Kenya

- Full summary as PDF

- Full summary as PDF for print

- Full summary in the browser

- Full summary (unformatted)

- Sub-Sarface Dams (SSD): June 22, 2018 (inactive)

- Sub-Sarface Dams (SSD): May 7, 2018 (inactive)

- Sub-Sarface Dams (SSD): July 17, 2018 (inactive)

- Sub-Sarface Dams (SSD): Aug. 15, 2018 (inactive)

- Sub-Surface Dams (SSD): Dec. 5, 2018 (inactive)

- Sub-Sarface Dams (SSD): Sept. 3, 2018 (inactive)

- Sub-Surface Dams (SSD): Nov. 2, 2021 (public)

View sections

Expand all Collapse all1. General information

1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

11/01/2018

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

These are constructions stretching across the sand filled dry riverbed, down towards the impermeable floor of the riverbed. They are totally submerged into the ground. For example by fully covering after construction by sand. This are done along dry rivers with huge sand deposits, which has high yield potential and where water can be easily extracted. The aim is to raise groundwater tables and increase the storage capacity for water withdrawals.

2.2 Detailed description of the Technology

Description:

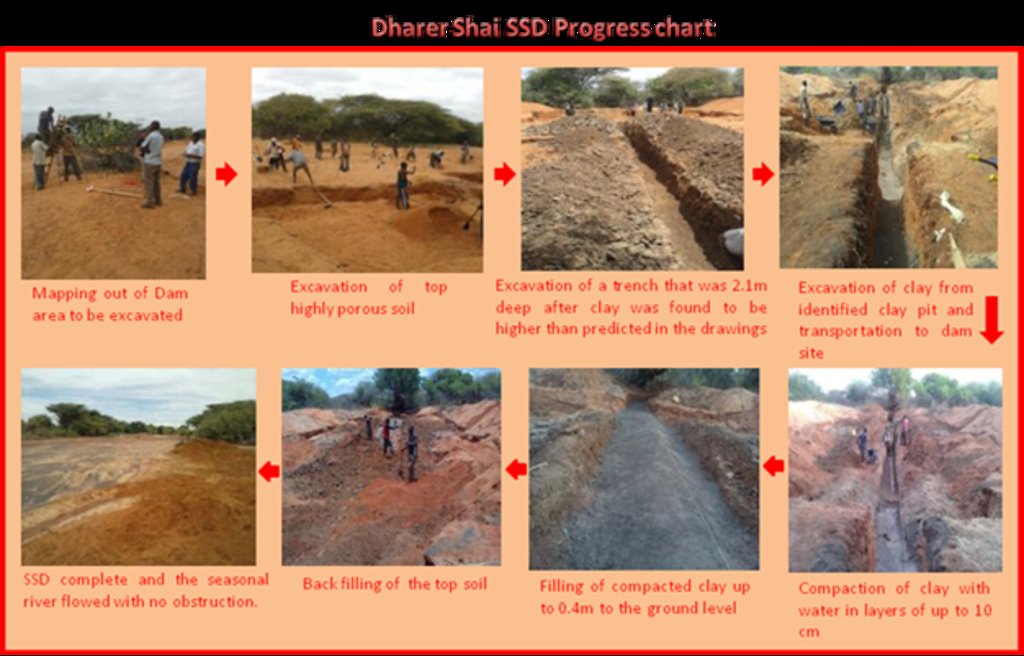

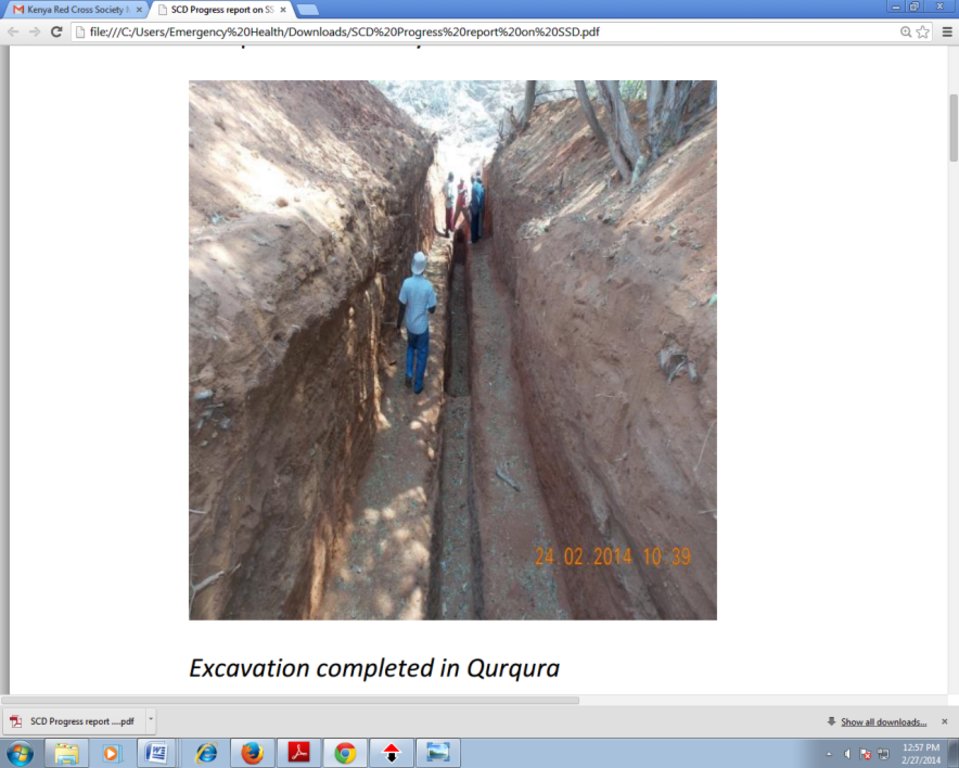

The technology is applied in northern rangeland of Isiolo County which is managed under communal management systems. The technology involves soil excavation which are typically subdivided into a number of square chambers measuring 4X2.3X2.2= 20.2M3 (not to scale). Then, excavation and transportation of clay soil from the clay pit and final compaction of clay soil after approximately a week, and lying out of the concrete and refilling of the sand. Finally, a liner is placed. The technology functions as underground water storage infrastructure. The development of Sub-Surface Dams (SSDs) was done through Cash for Work program where local labours comprising of 40-50 persons are engaged in excavation, compactions and developing the liners. Typical activities include, excavation of top porous soil, excavation of sample pits within the excavated area, checking filtration rates of soil, compaction of soil on which dam liners are laid, smoothing the sharp liners along which the dam liners are laid, making grooves to anchor the dam liner, laying the dam liner, anchoring the dam liner with a mixture of cement, water proof and sand with water (motor) and finally drying of the motor and filling back of sand. The technology aim to improve water access for livestock in ways that support wider management and utilization of the rangeland and as such strength the resilience of pastoralists to droughts. Inputs such as farm tools like jembe, panga, spades and human labour are required to develop SSD. The technology improves water supply/availability, thereby extending the period of livestock grazing in areas where typically water is depleted before the pasture. This effectively gives pastoral groups, an extra grazing time (typically 2 extra months) that is not too long to lead to land degradation through over-grazing but long enough to enable pastoralist utilize the remaining pasture in wet season grazing areas. In so doing, the technology enable balanced use of vast communal lands without livestock retreating to dry season grazing areas. The extended grazing period is instrumental in building resilience of pastoral communities in the face of climate variability. The technology was instrumental in fostering both balanced utilization of land and strengthening sustainable use of the vast rangeland by moderating the mobility between wet season and dry season grazing areas. The water stored through the technology stays longer, in this case study, the water lasted for 5 months after the end of the rainy season. Normally, the water is depleted within 2 months after the rainy period. The technology is also cheap and easy to understand and construct (especially in areas with clay as the underlying impermeable material) with a possibility of the communities to be taught how to identify suitable site and the entire process of construction. However, in areas without clay soil, the excavation of clay and transportation can be labour intensive and expensive.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Kenya

Region/ State/ Province:

Northern Kenya

Further specification of location:

Garba Tula, Isiolo County

Map

×2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- mitigate climate change and its impacts

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Grazing land

Extensive grazing land:

- Semi-nomadism/ pastoralism

Comments:

Communal grazing area that is shared by 2 and more pastoral groups

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- rainfed

Livestock density (if relevant):

Fluctuates, depending on seasons and pasture availability

3.4 SLM group to which the Technology belongs

- pastoralism and grazing land management

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

Sub-Surface Dams are only suitable in areas along the river, with suitable density of sand deposits

3.6 SLM measures comprising the Technology

structural measures

- S5: Dams, pans, ponds

3.7 Main types of land degradation addressed by the Technology

other

Comments:

Mismatch of pasture and water resources - there are areas where pastures are plenty but surface rain water is depleted earlier than pasture.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

Comments:

The SSD technology increase water availability is period immediately after the rain, hence ensuring better pasture utilization and more sustainable use of land

4. Technical specifications, implementation activities, inputs, and costs

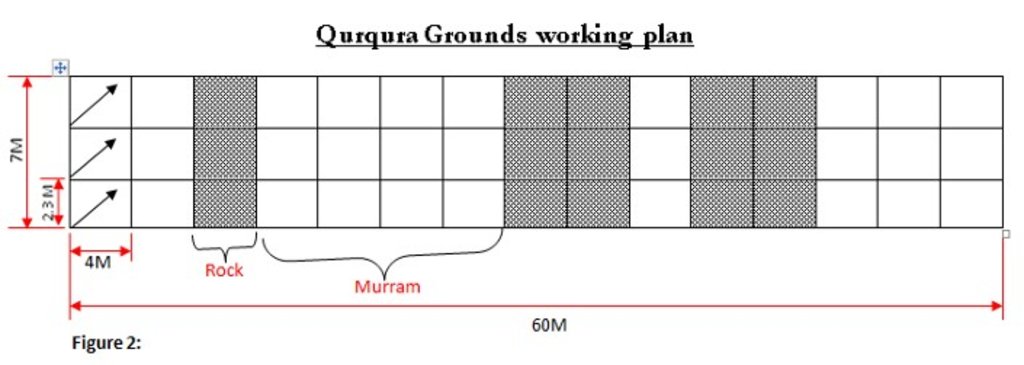

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

The SSD has initial excavation works. The construction of the SSD was constructed by 50 laborers. The design attached represent an Aerial view of the area of excavation that is subdivided into 45 square chambers of 4X2.3X2.2= 20.2M3 (not to scale). Each of the chambers were excavated by 5 laborers. The estimated time for excavation as per the plan was estimated to be five days. Excavation and transportation of the clay from the clay pit was estimated to take an approximate of five days while the compacting of the clay will follow one week later, and laying out of the concrete and refilling of the sand for another week. The liner will then be finally placed. in summary, the excavation of sand takes 5days, and the excavation of clay soil takes another 5days while concrete placing, compacting of clay as well as putting of liner and refilling of sand takes 10 days.

4.3 General information regarding the calculation of inputs and costs

Indicate average wage cost of hired labour per day:

3.5 USD per day

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Removing sand over dyke and Man-days for excavating and transporting soil to dam site | Other measures | 21 days for 45 casual labourers |

| 2. | Building and compaction soil in dam wall | Structural | 3 days for 45 casual labourers |

| 3. | Supplying water for compaction | Other measures | 0.5 day for 45 casual labourers |

| 4. | Back-filling sand on dam | Other measures | 1 day for 45 casual labourers |

| 5. | Supplying water for compacting soil in dam wall | Other measures | 2 days for 45 casual labourers |

| 6. | Compacting soil and placing liners | Other measures | 12 days for 45 casual labourers |

Comments:

The construction of SSD was done through “Cash for work” which is participatory process that involves community mobilization, identification of beneficiaries and formation of “Cash for work” committees, registrations and verification of beneficiaries and implementation/supervision of the work.

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | tools - jembe, spade etc. | pieces | 80.0 | 5.33 | 426.4 | |

| Labour | Removing sand over dyke and Man-days for excavating and transporting soil to dam site | per day | 945.0 | 4.0 | 3780.0 | |

| Labour | Building and compaction soil in dam wall | per day | 135.0 | 4.0 | 540.0 | |

| Equipment | Supplying water for compaction | per day | 22.5 | 4.0 | 90.0 | |

| Equipment | Back-filling sand on dam | per day | 45.0 | 4.0 | 180.0 | |

| Equipment | Supplying water for compacting soil in dam wall | per day | 90.0 | 4.0 | 360.0 | |

| Equipment | Compacting soil and placing liners | per day | 540.0 | 4.0 | 2160.0 | |

| Total costs for establishment of the Technology | 7536.4 | |||||

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Training of communities to manage and maintain the structures | Structural | yearly |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour for site protection and maintenance of hygiene | per site | 10.0 | 100.0 | 1000.0 | |

| Total costs for maintenance of the Technology | 1000.0 | |||||

Comments:

Water User Associations on the sites are trained on the management of the structures on behalf of the community e.g. on the protection of structure and hygiene maintenance.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Distance of the sub-surface dam from villages, extent of destruction by floods and human activities

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

because of the climate change, the rainfall is becoming more erratic

Indicate the name of the reference meteorological station considered:

Isiolo

Agro-climatic zone

- semi-arid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Soil texture (> 20 cm below surface):

- coarse/ light (sandy)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

poor/ none

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- high

Habitat diversity:

- high

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Semi-nomadic

Market orientation of production system:

- mixed (subsistence/ commercial

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

Individuals or groups:

- groups/ community

Level of mechanization:

- manual work

Gender:

- men

Age of land users:

- middle-aged

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- large-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

Land use rights:

- communal (organized)

Water use rights:

- communal (organized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

animal production

land management

Water availability and quality

water availability for livestock

Ecological impacts

Climate and disaster risk reduction

drought impacts

6.2 Off-site impacts the Technology has shown

water availability

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Long-term returns:

very positive

Comments:

The technology has limited running and maintenance costs once its done fairly well.

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| The technology created opportunity to graze in wet season grazing areas for extra 2 months period after rainy seasons. The technology has provided additional water that extended, albeit slightly, the grazing period of the land-users. In so doing, the land users utilized the pasture without retreating to traditional dry season grazing areas. |

| The extra grazing months has reduced overall livestock mortality during droughts and also improved resilience of pastoral community. |

| The distance traveled and effort required to access water was reduced. Community members reported reduced distances covered and time spent in search of water for livestock. In some instances the distance reduced from 12-15 Km to 3 Km. Community members also mentioned reduction in conflict incidences over water resources in some areas due to adequate supply of water as a result of construction of water infrastructure. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The technology has created an opportunity to optimally use the grazing area and overall reduced land degradation. The technology Improves access to water for livestock in ways which promote more sustainable management of rangeland resources and as such strengthening the resilience of local communities. |

| The validation process prior to construction of the SSD is draws critical lessons of identifying and agreeing on where to construct the SSD in a way that fit within broader sustainable rangeland management in a manner that ensured sustainable and efficient utilization of pasture and browse resources in targeted areas. The increase in water supply allowed livestock to graze additional 2-3 months in target areas before shifting to dry grazing areas where previously they migrated before exhausting the pasture and browse resources due to water scarcity. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| When the construction season for SSD is not well planned, there is likelihood/risks of the dams being washed away by flash floods. | Better planning and timing of the development of SDD, just slightly before the onset of rainfall. |

7. References and links

7.1 Methods/ sources of information

- compilation from reports and other existing documentation

7.3 Links to relevant information which is available online

Title/ description:

Promoting resilience by influencing water infrastructure development in community managed rangelands of Kenya

URL:

https://portals.iucn.org/library/sites/library/files/documents/2014-088.pdf

Title/ description:

Balancing water infrastructure in community-managed rangelands in the arid and semi-arid lands of Kenya

URL:

https://portals.iucn.org/library/sites/library/files/documents/2014-089.pdf

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules