Rotational grazing [Kenya]

- Creation:

- Update:

- Compiler: Paul Kahiga

- Editor: –

- Reviewers: Hanspeter Liniger, Donia Mühlematter, Fabian Ottiger

Rotational grazing

technologies_1741 - Kenya

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Gathenya Mwangi

Jomo Kenyatta University of Agriculture and Technology

P.O.Box, 62000-00200, Nairobi, Juja, Kenya

Kenya

SLM specialist:

Home Patrick

Jomo Kenyatta University of Agriculture and Technology

P.O.Box, 62000-00200, Nairobi, Juja, Kenya

Kenya

SLM specialist:

Chege Timothy

Jomo Kenyatta University of Agriculture and Technology

P.O.Box, 62000-00200, Nairobi, Juja, Kenya

Kenya

SLM specialist:

Omwange Abamba

Jomo Kenyatta University of Agriculture and Technology

P.O.Box, 62000-00200, Nairobi, Juja, Kenya

Kenya

SLM specialist:

Kimengich Baobab

Jomo Kenyatta University of Agriculture and Technology

P.O.Box, 62000-00200, Nairobi, Juja, Kenya

Kenya

SLM specialist:

Wamuongo Jane

+254 729 054547

Kenya Agricultural Research Institute

Nairobi

Kenya

SLM specialist:

Karanja Andrew

+254 729 054547

Kenya Agricultural Research Institute

Nairobi

Kenya

SLM specialist:

Namirembe Sara

+254-20-722-4000

World Agroforestry Centre

United Nations Avenue, Gigiri PO Box 30677-00100 Nairobi

Kenya

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Jomo Kenyatta University (Jomo Kenyatta University) - KenyaName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

KARI Headquarters (KARI Headquarters) - KenyaName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

International Centre for Research in Agroforestry (ICRAF) - Kenya1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

18/09/2012

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Rotational grazing is a process whereby livestock are strategically moved to fresh paddocks, or partitioned pasture areas, to allow vegetation in previously grazed pastures to regenerate.

2.2 Detailed description of the Technology

Description:

Mbeere South District is relatively dry and farmers have large chunks of land as compared to the Embu North District within the same county. Grazing is done on rotation from one piece of land to another depending on grass availability. Animals are either left to graze freely within the paddock or tethered depending on availability of laborer. In Mbeere South District, when the grass in paddocks gets exhausted, animals are fed on dry maize stalked harvested on the previous seasons. The dry maize stalks (fodder) is usually stored on a raised nest/perch where its covered from rain and sun.

Purpose of the Technology: Using this method cattle are concentrated on a smaller area of the pasture for a few days then moved to another section of pasture. This movement allows the grazed paddock a rest period that permits forages to initiate regrowth, renew carbohydrate stores, and improve yield and persistence.

Establishment / maintenance activities and inputs: When the animals have been shifted to the next paddock, this will allow grass and shrub to grow naturally and at the same time, the farmers are able to do repair of fence and hedge.

Natural / human environment: When utilized properly, rotational grazing can help farmers increase forage productivity. Rotational grazing can help improve productivity, weight gain or milk production per acre, and overall net return to the farm. Rotational grazing allows for better manure distribution that acts as a source of nutrients to the soil. Rotational grazing also has the potential to reduce machinery cost, fuel, supplemental feeding and the amount of forage wasted.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Kenya

Region/ State/ Province:

Eastern Province

Further specification of location:

Mbere South District

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- 10-50 years ago

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

- conserve ecosystem

3.2 Current land use type(s) where the Technology is applied

Grazing land

- Rotational grazing

Comments:

Major land use problems (compiler’s opinion): The area was predominantly bushy and over grazed with remarkable soil erosion.

Future (final) land use (after implementation of SLM Technology): Grazing land: Gi: Intensive grazing/ fodder production

If land use has changed due to the implementation of the Technology, indicate land use before implementation of the Technology:

Grazing land: Ge: Extensive grazing land

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 90, Longest growing period from month to month: January to March

Livestock density (if relevant):

25-50 LU /km2

3.4 SLM group to which the Technology belongs

- rotational systems (crop rotation, fallows, shifting cultivation)

3.5 Spread of the Technology

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, indicate approximate area covered:

- < 0.1 km2 (10 ha)

3.6 SLM measures comprising the Technology

management measures

- M2: Change of management/ intensity level

3.7 Main types of land degradation addressed by the Technology

biological degradation

- Bc: reduction of vegetation cover

Comments:

Main causes of degradation: land tenure

Secondary causes of degradation: overgrazing

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

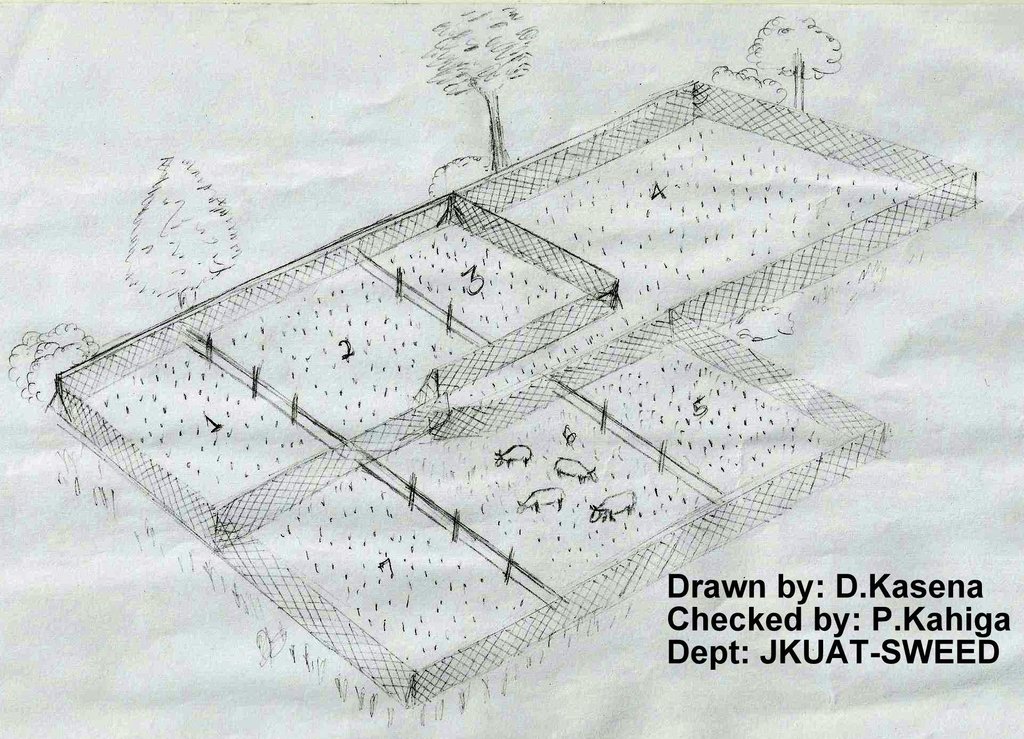

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

The technical drawing on the left shows a typical rotational grazing system. The animals are moved from one paddocks to the next on rotational basis.

Location: Mbeere South District. Eastern Province

Date: 30.11.2016

Technical knowledge required for field staff / advisors: low

Technical knowledge required for land users: moderate

Main technical functions: Allows for regeneration of pasture

Secondary technical functions: increase in nutrient availability (supply, recycling,…)

Change of land use practices / intensity level: Grazing in a particular paddock for sometime before moving the livestock in another paddock.

Major change in timing of activities: Rotational grazing

4.3 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Kshs

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

100.0

Indicate average wage cost of hired labour per day:

500.00

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Fencing | Management | Initial stage |

| 2. | Clearing the bushes | Management | Initial stage |

| 3. | Building the watering troughs and feeding points | Management | initial stages |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 250.0 | 250.0 | 100.0 |

| Equipment | Tools | ha | 1.0 | 200.0 | 200.0 | 100.0 |

| Construction material | Nails and barbes wire | ha | 1.0 | 100.0 | 100.0 | 100.0 |

| Construction material | Wooden post | ha | 1.0 | 50.0 | 50.0 | 100.0 |

| Total costs for establishment of the Technology | 600.0 | |||||

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Repairing of the fence | Management | when the livestock have moved to other paddocks |

| 2. | Repairing the watering points and feeding troughs | Management | when the livestock have moved to other paddocks |

| 3. | Moving the livestock to the subsequent paddocks | Management | any time of shift |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 200.0 | 200.0 | 100.0 |

| Equipment | Tools | ha | 1.0 | 150.0 | 150.0 | 100.0 |

| Construction material | Nails and barbes wire | ha | 1.0 | 50.0 | 50.0 | 100.0 |

| Construction material | Wooden post | ha | 1.0 | 30.0 | 30.0 | 100.0 |

| Total costs for maintenance of the Technology | 430.0 | |||||

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The most determining factors of this technology is labour and initial cost of constructing the paddocks and the overall maintenance.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

Thermal climate class: subtropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility: Medium

Soil drainage/infiltration: Medium

Soil water storage capacity: Medium

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

poor drinking water (treatment required)

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Difference in the involvement of women and men: Men build the paddocks while women move the livestocks

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

fodder production

fodder quality

animal production

risk of production failure

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Agricultural land used for grazing

SLM/ land degradation knowledge

conflict mitigation

Comments/ specify:

Animals are restricted and don't go to neighbours land

Improved livelihoods and human well-being

Comments/ specify:

Farmers have benefited from enhanced animal production

Ecological impacts

Soil

soil cover

nutrient cycling/ recharge

Biodiversity: vegetation, animals

animal diversity

6.2 Off-site impacts the Technology has shown

damage on neighbours' fields

Comments/ specify:

Animals don't stray

damage on public/ private infrastructure

Comments/ specify:

Animals don't stray

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

6.5 Adoption of the Technology

Comments:

There is a moderate trend towards spontaneous adoption of the Technology

Comments on adoption trend: The rotational grazing technology requires big grazing land unit

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| In rotational grazing, there is increase in forage production. |

| A well-managed rotational grazing system has low pasture weed establishment, majority of niches are already filled with established forage species. |

| Spreading of manure around the whole pasture land |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| In rotational grazing, there is need for more fence to be constructed | Construction of temporary fences that can be moved when need arises |

| More time is required to move the livestock from one paddock to the next one. | Adherence to the time schedules |

| In rotational grazing, there is a need to have water and access to shade from each smaller paddock. | The watering points can be automated |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules