Closed Pipe-conduit [China]

- Creation:

- Update:

- Compiler: Mei Zhao

- Editor: –

- Reviewers: Deborah Niggli, Alexandra Gavilano

Rat tunnel tillage

technologies_1556 - China

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Lingqin Meng

Division of water and soil conservation, Songliao water resources commission, ministry of water resources P.R. China

China

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Songliao Water Resources Commission (Songliao Water Resources Commission) - China1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

A Rat tunnel is a kind of subdrainage. It is a drainage duct formed through extrusion or oscillation in soil layer by pulling a mole plough with a tractor. The rat tunnels in a field should be used together with a concealed conduit drainage system in order to safely and quickly drains the water in the rat tunnels and avoid field collapses incurred by poor drainage and washings on the rat tunnels.

2.2 Detailed description of the Technology

Description:

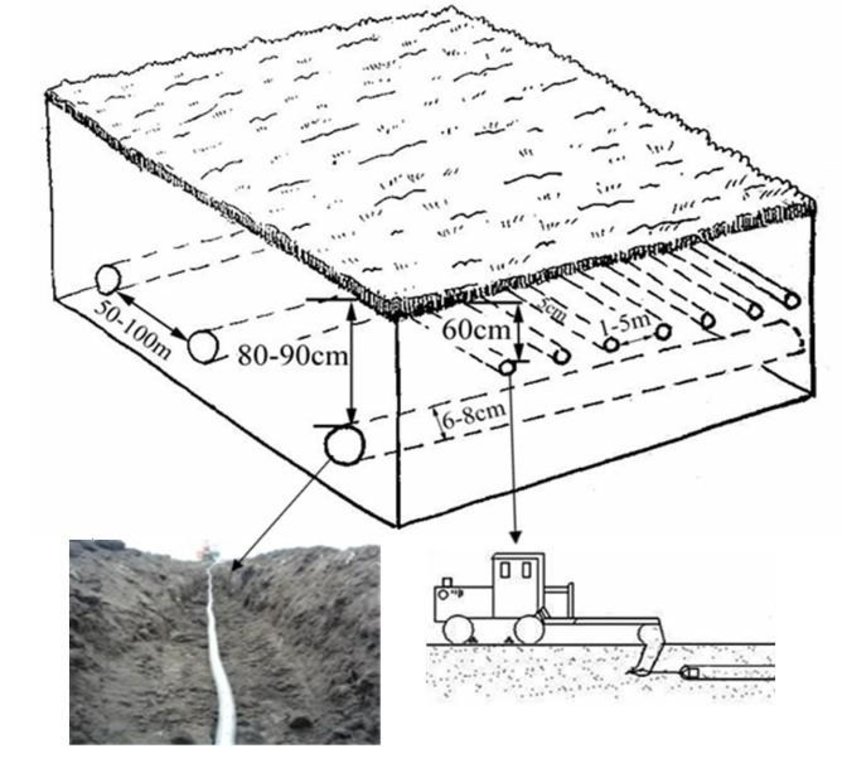

Rat tunnels are suitable for the regions with sticky and heavy soil, thick soil layer, and lower infiltration rates, high underground water level and where waterlogs are very likely to happen. By applying the rat tunnels, infiltration can be increased, soil salinization can be prevented without affecting the growth of the crops and occupying croplands. Good effect can be achieved by combining rat tunnels with closed conduits in application. Closed drainage refers to burying the drain pipes underground and letting the underground water flow along the fissures between the pipes and penetrate into the tubes and drained. In a field, if rat tunnels and closed conduits are combined for use, the rat tunnels constitute the first-grade drainage system, the closed conduits constitute the second-grade drainage system; the stagnant water in the plough layer penetrates through the soil and rat fissures and converges into the rat tunnels; While draining the water inside themselves to the outside, the rat tunnels collect the inside stagnant water and guide the water into the closed conduits, through which the water is discharged. In this way, the surface water can be discharged in a relatively thorough way.

Increase of soil infiltration, rapid discharge of direct surface runoffs, prevention of soil salinization.

In building such a project, the closed conduits should be built first, followed by the building of the rat tunnels; the closed conduits should be under the rat tunnels, the included angle between a closed conduit and a rat tunnel should be 90°.

The gap between two neighboring laid closed conduits should be 50m-100m. The burying depth of a closed conduit should be 80cm-90cm, the area around the closed conduit should be evenly laid with a layer of coarse gravels 5-8cm in thickness. After the project on the closed conduits in a field is accomplished, restore the flatness of the field surface, then undertake the operation on the rat tunnels.

In building the rat tunnels, a tractor is directly applied to pull the mole plough in accordance with the designed distances. When the tractor moves forward, the mole plough goes deep into a specified depth(generally 60cm) of soil layer and generates through piercing the soil along the direction of the forward motion of the tractor a tunnel(rat tunnels) whose diameter is equal to bullet diameter and which is in parallel with the ground surface. The separation distance between two neighboring rat tunnels is 1-5m. The service life is generally 2-5 years. If the rate of flow of a field obviously decreases, new rat tunnels should be built by averting the original routes.

After a rainfall, check whether the rat tunnels have collapsed. The service life of the newly laid closed conduits is over 20, however, new rat tunnels should be built every two years.

Rat tunnels are mainly distributed on the Three River Plain, which is the largest marsh distribution area. It has a total population of about 8.625, with the population density being about 79/km2. With the annual average temperature being 1℃-4℃,being warm in summer with the average temperature being over 22℃, having an annual amount of precipitation of 500-600 mm with the rainfall seasons mainly concentrated in the hot seasons from June to August, the Three River Plain is suitable for the growth of crops. The area is affluent in water resources, with the total quantity reaching about 18.764 billion/m3. In this area, the per capita cultivated land area is about 5 times of the average level in China. There are also about 2.52 millions of theropencedrymion distributed in the terrains with low mountains and hills.

2.3 Photos of the Technology

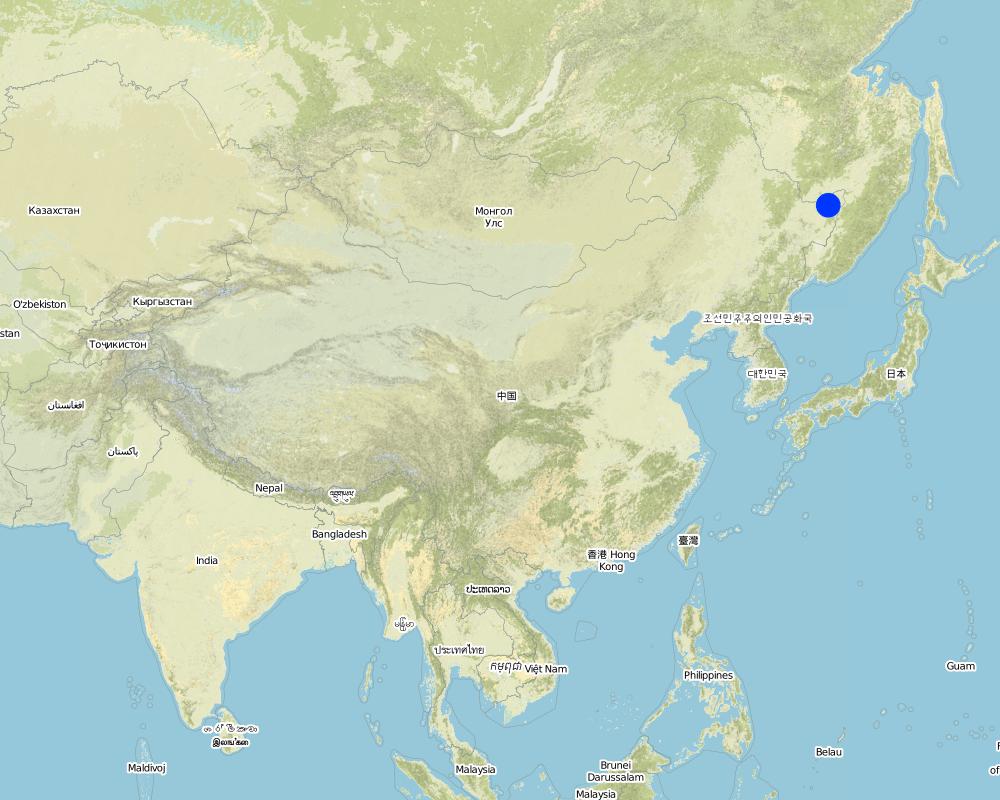

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

China

Region/ State/ Province:

Hei Longjiang

Further specification of location:

San Jiang Plain

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- > 10,000 km2

Comments:

This technology is widely used in San Jiang Plain.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- 10-50 years ago

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 150, Longest growing period from month to month: From April to September

Comments:

Major land use problems (compiler’s opinion): high underground water level, lower infiltration rates,Soil salinization

Major land use problems (land users’ perception): It's hard to drainage excess water. Lower soil fertility

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- water diversion and drainage

3.6 SLM measures comprising the Technology

structural measures

- S11: Others

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wm: mass movements/ landslides

soil erosion by wind

- Et: loss of topsoil

physical soil deterioration

- Pc: compaction

Comments:

Causes of degradation: soil management (Backward management modes), change of seasonal rainfall (The rainy seasons mainly focus on summer), Heavy / extreme rainfall (intensity/amounts) (The land can't drainge the excess water after downpours), population pressure (Population pressure makes extensive cultivation in this region), land tenure (As the lands are owned by country or by peasant communities, the peasants will not protect their land initiatively.), education, access to knowledge and support services (The channels for the local peasants get knowledge are few, and they will not learn knowledge initiatively.), governance / institutional

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- restore/ rehabilitate severely degraded land

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Diameter of closed conduit: 6-8cm, separation distance between two neighboring closed conduits: 50-100m, burying depth: 80-90cm: Diameter of rat tunnel: 5cm, separation between two neighboring rat tunnels: 1-5m, depth: 35-100cm(generally being 60cm). If the depth of the rat tunnels is >60cm, the depth of the closed conduit should be adequately increased.

Location: Hong Xing Farm. Hei Longjiang Province

Date: 2012-7-19

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: high (It's complicate to constructe this technology)

Main technical functions: increase of infiltration

Secondary technical functions: control of dispersed runoff: retain / trap, control of dispersed runoff: impede / retard, control of concentrated runoff: impede / retard, improvement of surface structure (crusting, sealing), improvement of topsoil structure (compaction), improvement of subsoil structure (hardpan), improvement of water quality, buffering / filtering water

Structural measure: Closed conduit

Vertical interval between structures (m): 0

Spacing between structures (m): 50-100

Depth of ditches/pits/dams (m): 8-9

Width of ditches/pits/dams (m): 0.06-0.08

Length of ditches/pits/dams (m): >50

Structural measure: Rat tunnel

Vertical interval between structures (m): 0

Spacing between structures (m): 1-5

Depth of ditches/pits/dams (m): 6

Width of ditches/pits/dams (m): 0.05

Length of ditches/pits/dams (m): >50

Construction material (other): A closed conduit is a kind of corrugated plastic conduit with the diameter generally being 6-8cm and

Slope (which determines the spacing indicated above): 0%

Lateral gradient along the structure: 0%

Author:

Zhao Mei, Beijing Normal University

4.2 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Ren Min Bi

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

6.25

Indicate average wage cost of hired labour per day:

60.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Layout the line of Closed Conduit | Spring |

| 2. | Laid closed conduits | Spring |

| 3. | Build rat tunnels.The tractor is directly applied to pull the mole plough in accordance with the designed distances. | Spring |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labour | ha | 1.0 | 64.0 | 64.0 | |

| Equipment | first machine | ha | 1.0 | 224.0 | 224.0 | |

| Equipment | second machine | ha | 1.0 | 24.0 | 24.0 | |

| Construction material | corrugated plastic conduit | ha | 1.0 | 640.0 | 640.0 | |

| Total costs for establishment of the Technology | 952.0 | |||||

| Total costs for establishment of the Technology in USD | 152.32 | |||||

Comments:

Duration of establishment phase: 1 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Build rat tunnels. | every two years |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | second machine | ha | 1.0 | 24.0 | 24.0 | |

| Total costs for maintenance of the Technology | 24.0 | |||||

| Total costs for maintenance of the Technology in USD | 3.84 | |||||

Comments:

Machinery/ tools: Mole Plough, refer to the photo of technical drawing.

The accounted costs for each hectare are as follows: Depth, diameter and spacing on closed conduit: being 90cm, 8cm and 80m respectively, the closed conduits with a total length of 200m are required for each hectare. 1. Costs of closed conduit laying: Tractor cost is 224$US ; Expense of the conduit materials is 640$US; Labor expense is 64$US. 2. Costs of rat tunnel building: Machinery cost: 24$US/hectare (the operation efficiency: 30 hectare/day). No maintenance cost. However, new rate tunnels should be built with the same costs(24$US) every 2 years. The service life of the closed conduits is over 20 years.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The most determinate factors is the cost of corrugated plastic conduit.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- sub-humid

- semi-arid

Thermal climate class: temperate, boreal

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

excess

Water quality (untreated):

for agricultural use only (irrigation)

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial)

- commercial/ market

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

- rich

Individuals or groups:

- groups/ community

Level of mechanization:

- manual work

- mechanized/ motorized

Gender:

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Population density: 10-50 persons/km2

Annual population growth: < 0.5%

10% of the land users are very rich.

45% of the land users are rich.

35% of the land users are average wealthy.

10% of the land users are poor.

Off-farm income specification: Apart from farming, the main works of the local people involve doing works for others in cities and towns or doing business.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- large-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

- communal/ village

Land use rights:

- communal (organized)

Water use rights:

- communal (organized)

Comments:

The lands are owned by country or by peasant communities.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

fodder production

fodder quality

animal production

wood production

product diversity

production area

Water availability and quality

drinking water availability

Income and costs

farm income

diversity of income sources

economic disparities

workload

Socio-cultural impacts

cultural opportunities

community institutions

national institutions

SLM/ land degradation knowledge

conflict mitigation

situation of socially and economically disadvantaged groups

contribution to human well-being

Comments/ specify:

Local peasants learn some knowledges of soil and water conservation though this technology.

Ecological impacts

Water cycle/ runoff

water quantity

water quality

harvesting/ collection of water

surface runoff

excess water drainage

groundwater table/ aquifer

evaporation

Soil

soil moisture

soil loss

soil crusting/ sealing

salinity

6.2 Off-site impacts the Technology has shown

water availability

reliable and stable stream flows in dry season

downstream flooding

downstream siltation

groundwater/ river pollution

buffering/ filtering capacity

damage on neighbours' fields

damage on public/ private infrastructure

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

slightly positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly negative

Long-term returns:

positive

6.5 Adoption of the Technology

- > 50%

If available, quantify (no. of households and/ or area covered):

95% of all households

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

This technology only be implemented by farmers, because it's too expensive for peasant to afford it. If farmers implement the technology, the local government will organization peasants to help farmers, the government pay for the wages.

A few of land users will implement the technology without any external material support.

There is a little trend towards spontaneous adoption of the Technology

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Fast drainage of surface water |

| Prevention of soil salination |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| New rat tunnels should be built every two years |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Complicated in construction, big investment | seeking other substitutes |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

28/02/2013

7.2 References to available publications

Title, author, year, ISBN:

Techniques standard for comprehensive control of soil erosion in the black soil region, Author: Shen Bo; Meng Lingqin, Years: 2009

Available from where? Costs?

Internal book

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules