Logs to reduce surface run-off during the rainy season [Lao People's Democratic Republic]

- Creation:

- Update:

- Compiler: kang phanvongsa

- Editors: Vardsana Buavanxay, Bounthanom Bouahom

- Reviewers: Nicole Harari, Stephanie Jaquet, Alexandra Gavilano

technologies_2279 - Lao People's Democratic Republic

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Bounlert

Lao People's Democratic Republic

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

National Agriculture and Forestry Research Institute (NAFRI) - Lao People's Democratic Republic1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Logs to reduce surface run-off during the rainy season.

2.2 Detailed description of the Technology

Description:

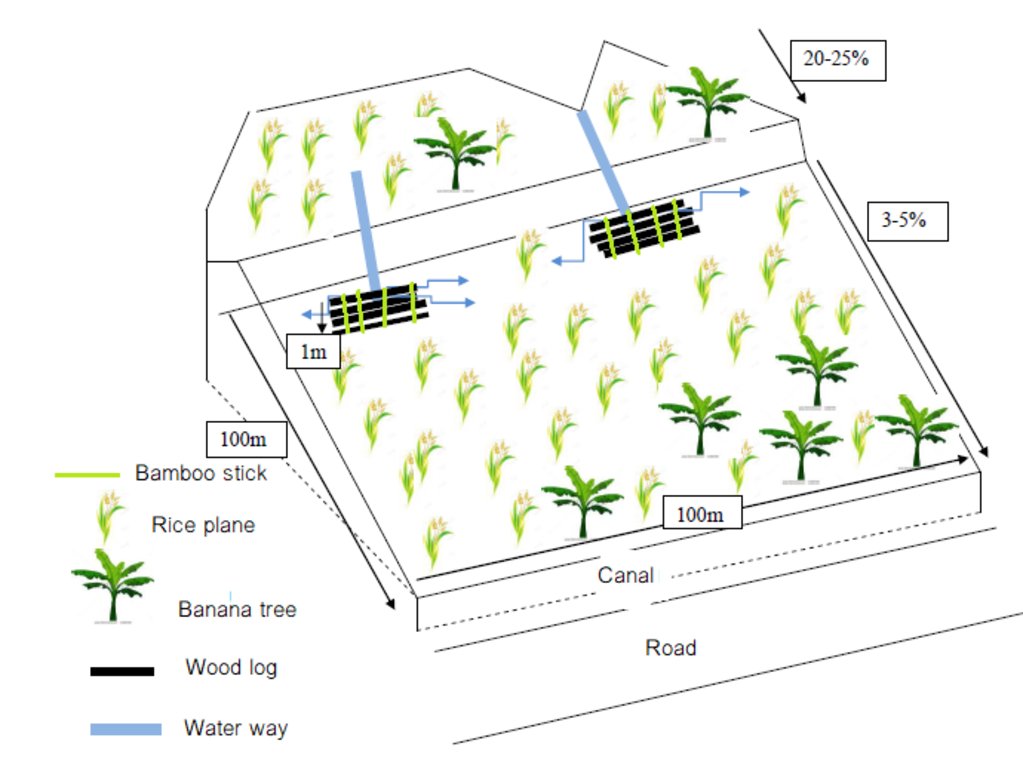

In the upland areas with 3-5 % at foot slopes and 16-30% hill slopes of Lao PDR rotational shifting cultivation has been the primary means of the local people’s livelihood for many generations. Given the topography of the area with its hill slopes it restricts the opportunities for agricultural development. After the land on foot slopes has been cleared and the remaining vegetation burned off in preparation for agricultural activities there are significant impacts on land use particularly during the rainy season which occurs between May-November. There are heavy downpours especially in the months of September and October that create significant sediment transport along the mountain valleys and it also results in flushing organic matter on the surface being flushed along the road sides and ending up in waterways. Furthermore decayed vegetation is washed over the crops. The negative impacts experienced from the loss of fertile topsoil motivated many of the land users to develop some kind of technology in 2015 that could control this run-off from the mountains.

This technology was also meant to help maintain nutrient levels on topsoil as without a technology the nutrients are being flushed down the hillside. It can be assembled using a collection of local logs approximately 4-5 meters in length and around 15-20 cm in diameter (obtained through the clearance of upland rice fields). The logs should be arranged horizontally at the position of a designated drainage site where the run-off flows from a particular agricultural area. They should be stacked on top of one another until reaching a height of about 1 meter. A buttress should also be erected using mature bamboo poles as supporting posts with a length of 1.5 meters and diameter of about 10 cm so as to prevent the logs from sliding down the hillside. The bamboo poles should be driven about 50 cm into the ground and then tightened with ropes. This technology should only be constructed after the planting of upland rice fields has been completed in mountainous areas which have slopes between 20-25%. In general, the local residents have set up this mechanism at 2-3 selected sites within an agricultural plot. The benefits of this technology include mitigating the impacts of soil run-off whilst facilitating the distribution of soil nutrients around the agricultural plot of land. The water and top soil run-off is slowed down when it reaches the log wall and is then directed to flow out on either side of the technology. Previously the average rice yield used to be 1.5 tons/ha, but then the upland rice yields increased to 2 tons/ha after the application of this technology. This is due to the reduction of soil surface losses and an increase in the soil’s organic matter that accumulates through the processes of sedimentation and biomass transport. The quality of the surrounding soil improves through the decay of biomass and the breakdown of the soil by organisms such as earthworms and millipedes.

This technology can be installed on hill slopes . The technology is approximately 1 meter in height (above ground) and 4 -5 meters in length. The supporting posts need to be driven 50 cm into the ground. This technology can be used at the location of seasonal drainage points or water channels on hill slopes between 20-25% (with usually 2 or 3 sites per agricultural plot).

Strengths: Reduces sediment run-off, increases organic matter on the soil’s surface (builds a thicker layer of soil), financially economical, and distributes nutrients on agricultural plots.

Weaknesses disadvantages/ risks of the technology/ how to overcome them: Most of these technologies are not permanent and quite exposed and therefore require annual repair and maintenance. If the run-off facility is to be upgraded, it would need the use of a better quality of rope and concrete posts. However, most people still use the readily available local materials which affects the quality of the water run-off technology as well as its effectiveness. Furthermore this technology may need to be installed at several sites along the same channel on the foot slopes.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Lao People's Democratic Republic

Region/ State/ Province:

Attapue Province

Further specification of location:

Phouvong District, North Vongvillay village

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

Applied where water or erosion canals occur in the rice field.

Map

×2.6 Date of implementation

Indicate year of implementation:

2015

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- reduce risk of disasters

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Perennial (non-woody) cropping

Annual cropping - Specify crops:

- cereals - maize

- cereals - rice (upland)

- root/tuber crops - cassava

Perennial (non-woody) cropping - Specify crops:

- banana/plantain/abaca

- sugar cane

Number of growing seasons per year:

- 1

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- cross-slope measure

3.6 SLM measures comprising the Technology

structural measures

- S6: Walls, barriers, palisades, fences

- S11: Others

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wo: offsite degradation effects

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

The technique is applied on foot slope area

Wooden log barriers are created with hight of 1 meter from the surface.

The length of the logs is about 4-5 meters .

Depth of the bamboo post into the soil is 50 centimeters to hold the logs,

This technique is implement on the top of the rice field at the slope 20-25%, where the water form natural surface canals.

Author:

Vadsana Boualaivan

Date:

18/05/2017

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

2 wooden log barriers

Specify dimensions of unit (if relevant):

Width: 4-5 meters / High 1 meter (1 barrier)

other/ national currency (specify):

kip

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

8000.0

Indicate average wage cost of hired labour per day:

50000

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Collect the wood logs and bamboo postsv | After harvesting |

| 2. | Bury the bamboo post | |

| 3. | Arrange the wood |

Comments:

place on the water canal to reduce water flow

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labor ( for two barriers ) | person-day | 2.0 | 50000.0 | 100000.0 | 100.0 |

| Equipment | hoe | piece | 1.0 | 50000.0 | 50000.0 | 100.0 |

| Equipment | shovel | piece | 1.0 | 25000.0 | 25000.0 | 100.0 |

| Equipment | hummer | piece | 1.0 | 20000.0 | 20000.0 | 100.0 |

| Plant material | timber logs (for two barriers) | piece | 10.0 | 100.0 | ||

| Plant material | bamboo (for two barriers ) | stick | 10.0 | 100.0 | ||

| Total costs for establishment of the Technology | 195000.0 | |||||

| Total costs for establishment of the Technology in USD | 24.38 | |||||

Comments:

Regarding the construction material:bamboo and dead wooden logs are for free, as they are collected from the surrounding.

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Repair of the barrier | 2 times a year |

Comments:

using residue material in the nature for maintenance

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labor (for two barriers ) | person | 2.0 | 50000.0 | 100000.0 | 100.0 |

| Equipment | knife | piece | 2.0 | 25000.0 | 50000.0 | 100.0 |

| Equipment | shovel | piece | 1.0 | 20000.0 | 20000.0 | 100.0 |

| Construction material | timber ( for two barriers ) | piece | 10.0 | 100.0 | ||

| Construction material | bamboo ( for two barriers ) | stick | 10.0 | 100.0 | ||

| Total costs for maintenance of the Technology | 170000.0 | |||||

| Total costs for maintenance of the Technology in USD | 21.25 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The equipment is the most important factor affecting the costs.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

2500.00

Specifications/ comments on rainfall:

From May to September there is more rain, highest between July and September and it decreases to lowest from November to April

Indicate the name of the reference meteorological station considered:

Phouvong district natural resource office

Agro-climatic zone

- sub-humid

The average annual temperature is 26.2 °C

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- concave situations

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- fine/ heavy (clay)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- men

Age of land users:

- children

- middle-aged

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- open access (unorganized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

1.5 ton/ha

Quantity after SLM:

2 tons/ha

Comments/ specify:

Increase in organic matter from surface accumulation

production area

Comments/ specify:

Before farmer lossed a lot of surface due to the water channels in the cultivation area; after wood log barriers has been constructed runoff stopped, and surface area increased by soil accumulation

Income and costs

farm income

Comments/ specify:

Previously water flow on the production area caused damages to crops and in consequence reduced crop yield

workload

Comments/ specify:

Installing wood log barriers to extend the cultivation area requires more labour

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Food security has been improved because the farmer get more yield and can sale the surplus even in the local market

Ecological impacts

Water cycle/ runoff

surface runoff

Comments/ specify:

The water and top soil run-off is slowed down when reaching the log barrier and the water is directed on either side. Thus, heavy surface runoff is stopped efficiently.

Soil

soil loss

Comments/ specify:

Before a lot of top soil by water leaching on the soil surface was lost. After the installation of the wooden log barrier water way changed and spread sediments to the area and reduced accumulation in the road canal

Biodiversity: vegetation, animals

biomass/ above ground C

Comments/ specify:

Wooden log barriers can spread biomass and plant fragment and sediment to production area (increase topsoil)

Climate and disaster risk reduction

landslides/ debris flows

Comments/ specify:

Before heavy rains caused soil erosion (rill or sheet erosion between row) in rainy season

6.2 Off-site impacts the Technology has shown

damage on neighbours' fields

Comments/ specify:

Before water way flow through owners land. After the installation of the technology the water way was changed to neighborhoodt without causing damages there.

Sediment run-off into the road canal

Comments/ specify:

Before the sediments from the rill erosion went directly into the road canal. After wood logs installation sedement remained mostly on the field

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | moderately | |

| seasonal temperature | wet/ rainy season | increase | very well |

| annual rainfall | increase | well | |

| seasonal rainfall | wet/ rainy season | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | moderately |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| extreme winter conditions | well |

| drought | moderately |

| forest fire | moderately |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| landslide | moderately |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| extended growing period | not well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

slightly positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

neutral/ balanced

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 91-100%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Reduce sediment run-off |

| Increased organic matters on soil surface (create thicker soil layer) |

| Low cost for implementation |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Better distribution of nutrients on agricultural lands. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Most of these facilities are not permanent and vulnerable which require repair every year | It may require better rope quality and concrete posts. |

| Some sediment accumulation are still caused by remaining run-off sites | must create many point of barrier |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| People still use available local materials which affects the quality of the water run-off facility as well as its effectiveness. | It may require installation of this kind of facility in many sites along the same channel depending on slope of the land. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

1 place

- interviews with land users

1 person

When were the data compiled (in the field)?

18/05/2017

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules