Bio Gas [Nepal]

- Creation:

- Update:

- Compiler: Sabita Aryal

- Editor: –

- Reviewers: David Streiff, Alexandra Gavilano

Gobar gas (nepali)

technologies_1235 - Nepal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Pantha Samikshya

Kathmandu University

Nepal

SLM specialist:

Giri Gyanu

Kathmandu University

Nepal

SLM specialist:

Piya Shristi

Kathmandu University

Nepal

SLM specialist:

Baidya Khatri Raghuram Ratna

Sarada Batase VDC

Nepal

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Kathmandu University (KU) - NepalName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Sarada Batase Village Development Committee (Sarada Batase VDC) - Nepal1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Production of fuel and manure from animal waste

2.2 Detailed description of the Technology

Description:

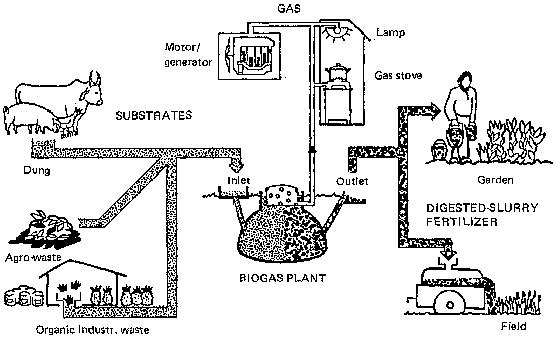

People here use animal as well as human waste for the production of biogas.Equal amount of dung and water is poured in the inlet and mixed by the help of mixture.Then the raw materials are passed to the digestor where gas (methane) is produced by an anerobic fermentation by methanogenic bacteria. The produced gas is collected in dome and slurry is drained out through an outlet.

Purpose of the Technology: The biogas produced from the plant is used as a fuel for cooking food. The bio gas produced can also be used to light bulbs.The slurry can be used as manure in agricultural fields.

Establishment / maintenance activities and inputs: About 24% houses is using this technique by the funds from international , national (government) and few by self funding . The digester should be cleaned every five years of its use.

Natural / human environment: Temperature maintenance is basic requirement for biogas production. (36 degree celsius).

It is most favorable if the plant is near the water resources and near to the fuel source i.e. cattle house.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Nepal

Region/ State/ Province:

Nepal

Further specification of location:

Kavre

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- > 10,000 km2

Comments:

Boundary points of the Technology area: Altitude about 4900 feets

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- 10-50 years ago

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Tree and shrub cropping

Annual cropping - Specify crops:

- root/tuber crops - potatoes

Tree and shrub cropping - Specify crops:

- citrus

Comments:

Major cash crop: Potatoes and oranges

Major land use problems (compiler’s opinion): Loss of fertile soil

Future (final) land use (after implementation of SLM Technology): Cropland: Ca: Annual cropping

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

3.5 SLM group to which the Technology belongs

- energy efficiency technologies

3.6 SLM measures comprising the Technology

agronomic measures

- A7: Others

Comments:

Type of agronomic measures: better crop cover, manure / compost / residues

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

Comments:

Main causes of degradation: deforestation / removal of natural vegetation (incl. forest fires), inputs and infrastructure: (roads, markets, distribution of water points, other, …)

Secondary causes of degradation: crop management (annual, perennial, tree/shrub), over-exploitation of vegetation for domestic use, overgrazing, change in temperature, change of seasonal rainfall, Heavy / extreme rainfall (intensity/amounts), wind storms / dust storms, floods, droughts, population pressure, land tenure, poverty / wealth, labour availability, governance / institutional

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

First a pit is dug, perhaps ten feet deep. Then a water tight cement cylinder is constructed. Intake and outgo pipes are installed. The whole unit is made water tight. The manure is mixed with water in the intake basin to make slurry which then goes down the pipe to the digester. This whole cylinder is filled. Meanwhile, the whole mass bubbles methane up to the top. The gas builds the pressure and can be taken off through a rubber tube to a gas stove in the kitchen. When the cylinder is full the effluent comes out through the outer inlet, which is the byproduct of the plant and is the fertilizer for the field.

Location: Sarada Batase , VDC

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: moderate

Main technical functions: stabilisation of soil (eg by tree roots against land slides)

Secondary technical functions: increase in organic matter, increase in nutrient availability (supply, recycling,…), spatial arrangement and diversification of land use

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | unit | 1.0 | 4500.0 | 4500.0 | |

| Equipment | Animal traction | unit | 1.0 | 5765.0 | 5765.0 | |

| Total costs for establishment of the Technology | 10265.0 | |||||

| Total costs for establishment of the Technology in USD | 10265.0 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Digestor cleaning | 5 years |

| 2. | Refilling the digestor | Daily |

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

1) Size of biogas plant

2) Materials required to build the plant

3) Labour Cost

5. Natural and human environment

5.1 Climate

Agro-climatic zone

- sub-humid

- semi-arid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Landforms: Also valley floors

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility is high - medium

Soil water storage capacity is high

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

good

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

- commercial/ market

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

- mechanized/ motorized

Indicate other relevant characteristics of the land users:

Population density: 100-200 persons/km2

Annual population growth: 1% - 2%

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

Land use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

wood production

production area

energy generation

Income and costs

expenses on agricultural inputs

farm income

workload

Comments/ specify:

No need to collect wood

Socio-cultural impacts

food security/ self-sufficiency

health situation

livelihood and human well-being

Comments/ specify:

With the help of this technology the living standard of rural women and men has been improved. It has increased the employment as well as productivity. It has also reduce dependency on traditional energy and attain sustainable development via integrating the alternative energy with the socio-economic activities of women and men in rural communities.

Ecological impacts

Water cycle/ runoff

surface runoff

Soil

soil moisture

nutrient cycling/ recharge

soil organic matter/ below ground C

Biodiversity: vegetation, animals

biomass/ above ground C

pest/ disease control

Climate and disaster risk reduction

emission of carbon and greenhouse gases

6.2 Off-site impacts the Technology has shown

groundwater/ river pollution

damage on neighbours' fields

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | not well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

neutral/ balanced

6.5 Adoption of the Technology

Comments:

There is a little trend towards spontaneous adoption of the Technology

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| used as a fertilizer |

| Efficient cooking method. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Decreases the dependency on wood. |

| Reduces health problems due to air pollution. |

| Improves the living standard of rural men and women. |

| Use of alternative energy resources. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Size of digestion is too big due to which its requirement cannot be fulfilled. | Size should be maintained according to the available resources. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| If methane produced is leaked in atmosphere can sustain global warming. | Should be well constructed. |

| leakage from the plant may be mixed in the water sources. | Prevent leakage with timely maintainance. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

07/01/2015

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules