Treadle Pump [Nepal]

- Creation:

- Update:

- Compiler: Shreedip Sigdel

- Editor: –

- Reviewers: David Streiff, Alexandra Gavilano

Laxmi Dhiki Pump (Main Contributor: Purusottam Gupta, IDE-Nepal)

technologies_1690 - Nepal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Gupta Purusottam

IDE-Nepal

Nepal

SLM specialist:

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

ICIMOD International Centre for Integrated Mountain Development (ICIMOD) - NepalName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

iDE Nepal (iDE Nepal) - Nepal1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

A treadle pump is a foot operated water lifting device that can be used by smallholder farmers to irrigate their land in places where the water table is high.

2.2 Detailed description of the Technology

Description:

A treadle pump is a simple, cheap, and effective device for lifting water. In this technology, bamboo levers are pushed repeatedly by foot to provide the driving power to lift water. This simple device is relatively easy to install and maintain and is environmentally friendly. Three types of treadle pumps are in common use; all three use the cylinder and paddle concept, but the model which uses a cylinder 8.9 cm in diameter and has bamboo paddles is the one most commonly favoured by farmers in the region. It is cheaper and can lift more water than a comparable hand pump. On average, a treadle pump can be used to lift water from about 6 m underground and one such pump can irrigate as much as 0.34 ha of land (depending on the soil type and other conditions). In addition to lifting water for irrigation, the treadle pump can also be used for a variety of domestic purposes. In the Terai areas of Nepal, it is also widely used as a means of generating income.

When farmers consider installing a treadle pump, they first need to verify whether there is sufficient groundwater to merit the expense. Treadle pumps should be installed by trained technicians and properly maintained throughout their lifetime. If possible, an extra set of spare parts should always be kept on hand and a trained technician should be consulted for major repairs.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Nepal

Further specification of location:

Banke, Bardiya, Dailekh, Surkhet, Kaski, Dhanusha, Kapilbastu, Rupandehi, Jhapa, and Salyan District

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- 1,000-10,000 km2

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- Simplified irrigation

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Number of growing seasons per year:

- 2

Comments:

Major land use problems (compiler’s opinion): Most agriculture in Nepal is rainfed. There is a general scarcity of water for irrigation and the availability of the water that exists is limited by economic and energy constraints.

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- irrigation management (incl. water supply, drainage)

3.6 SLM measures comprising the Technology

structural measures

- S7: Water harvesting/ supply/ irrigation equipment

3.7 Main types of land degradation addressed by the Technology

water degradation

- Ha: aridification

Comments:

Main causes of degradation: Water not available for Irrigation, Soil moisture is decreasing, crop productivity is declining

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

4. Technical specifications, implementation activities, inputs, and costs

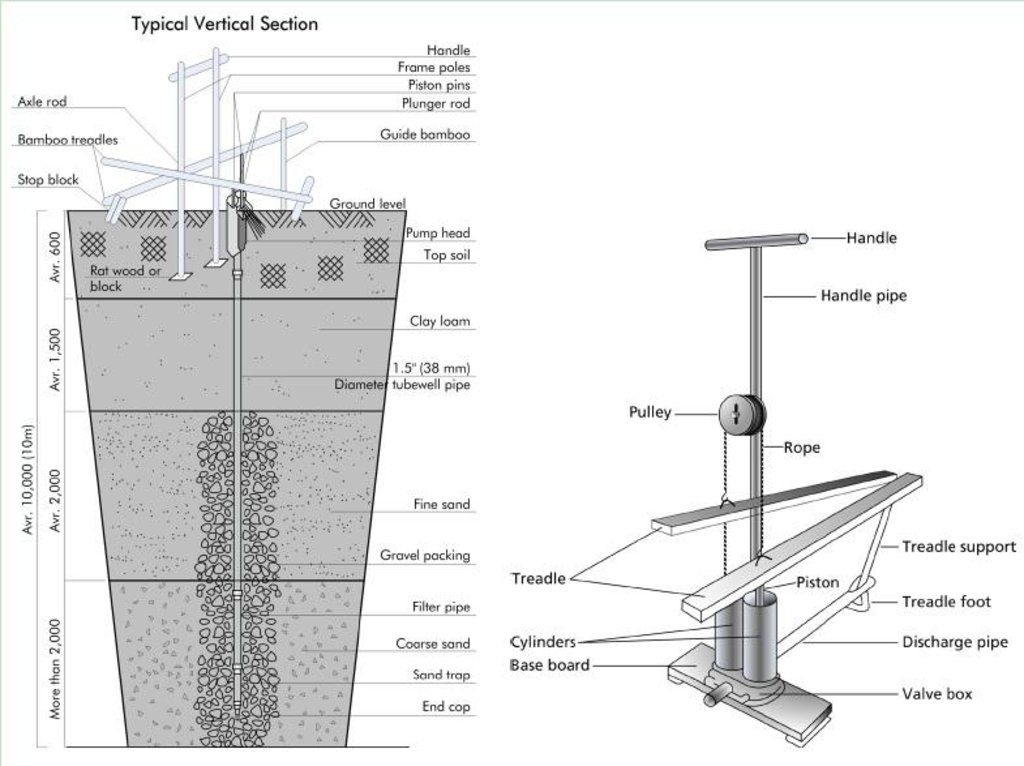

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Components of a treadle pump

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: low

Technical knowledge required for Field Technician:

Main technical functions: increase / maintain water stored in soil, Increase supply of water

Secondary technical functions: improvement of topsoil structure (compaction), improvement of subsoil structure (hardpan), spreads water

Author:

Purusottam Gupta, AK Thaku

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Waterpump

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

5.33

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | The site first needs to be evaluated in order to verify whether sufficient groundwater is available. | |

| 2. | The pump should be installed by a trained technician. |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Evaluate site and installing pump | persons/day/unit | 3.0 | 5.3333 | 16.0 | 100.0 |

| Construction material | Various materials | unit | 1.0 | 43.0 | 43.0 | 100.0 |

| Total costs for establishment of the Technology | 59.0 | |||||

| Total costs for establishment of the Technology in USD | 59.0 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | The pump needs to be maintained on a regular basis and, if possible, an extra set of spare parts should be kept on hand. A trained technician should be consulted for major repairs | |

| 2. | Routine maintenance activities are: Repairing or replacing the treadle frame |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Maintaining pump | persons/day/unit | 2.0 | 4.0 | 8.0 | 100.0 |

| Construction material | Various material | unit | 1.0 | 5.0 | 5.0 | 100.0 |

| Total costs for maintenance of the Technology | 13.0 | |||||

| Total costs for maintenance of the Technology in USD | 13.0 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

This is an average cost estimate, the actual cost will be a function of the soil type, how far the water table is below the surface, and the type and quality of the materials used (metallic vs. non-metallic, timber vs. bamboo) and the cost of labour.All costs and amounts are rough estimates by the technicians and authors.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- sub-humid

Thermal climate class: subtropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility is medium

Soil drainage / infiltration is good

Soil water storage capacity is high

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

poor/ none

Water quality (untreated):

for agricultural use only (irrigation)

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

- animal traction

Indicate other relevant characteristics of the land users:

Population density: > 500 persons/km2

Annual population growth: 1% - 2%

50% of the land users are average wealthy.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- communal (organized)

5.9 Access to services and infrastructure

All services access (low to moderate):

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

product diversity

Comments/ specify:

Increase crop diversification

production area

land management

Comments/ specify:

Farming can continue through period of drought

Water availability and quality

irrigation water availability

Income and costs

farm income

workload

Socio-cultural impacts

cultural opportunities

recreational opportunities

conflict mitigation

situation of socially and economically disadvantaged groups

livelihood and human well-being

Comments/ specify:

Increased farm income helps to improve the lives and livelihoods of smallholder farmers, and of other socially and economically disadvantaged groups

Ecological impacts

Water cycle/ runoff

water quantity

surface runoff

Soil

soil moisture

Other ecological impacts

natural water table if water is continuously drawn

the land close to the pump area remains wet and swampy

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| seasonal rainfall extremes | well |

Comments:

A larger bore (12.7 cm) treadle pump can be used to access deeper in the water table where more water may be available

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

positive

6.5 Adoption of the Technology

Comments:

There is a strong trend towards spontaneous adoption of the Technology

Comments on adoption trend: Land users are quick to adopt this technology voluntarily even without any external support.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

It meets the need for a low-cost irrigation measure and is accessible to farmers How can they be sustained / enhanced? Sustained effort by the government to disseminate information, assist INGOs and local people to get started. |

|

Can be manually operated and does not require any sophisticated or skilled manpower How can they be sustained / enhanced? Make it even easier, simpler, and cheaper to buy and maintain by introducing improved methods and techniques |

|

Does not require electricity or any other external form of energy so it is easy to implement even in remote places How can they be sustained / enhanced? Continue efforts at research and development to make the pumps even more effective |

|

It is an affordable technology for growing vegetables. Purchase and installation are within the means of most farmers and it is easy to maintain. Technical know-how for installation is available locally. How can they be sustained / enhanced? Continue research and development to make pumps even more effective. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Requires manpower. It irrigates only a limited area. | Continue research and development to make it even simpler to use, possibly even by those who are not so physically fit. |

| Requires continuous inspection and maintenance and a supply of spare parts (washer, check valve, bamboo poles) | Continue research and development to make it even more robust without the need for vigilant maintenance. |

| Over time, the pumps pump less water, there is frothing, and sand is also lifted | The joints and sockets need tightening. The right place should be selected for boring and, after installation; the area needs to be packed with gravel. |

| At times the pump has trouble lifting water, it is not working properly | Check the treadle frame installation. Check that the size of the washer is appropriate. |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

Technical guideline for treadle pump installation and maintenance. Kathmandu, Nepal, IDE-Nepal

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules